Lubrication improved step chain

A chain and step technology, which is applied in the direction of belt/chain/gear, chain elements, escalators, etc., can solve the problems of insufficient and effective lubrication, high maintenance cost, high manufacturing cost, etc., to improve lubrication effect, reduce maintenance cost, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

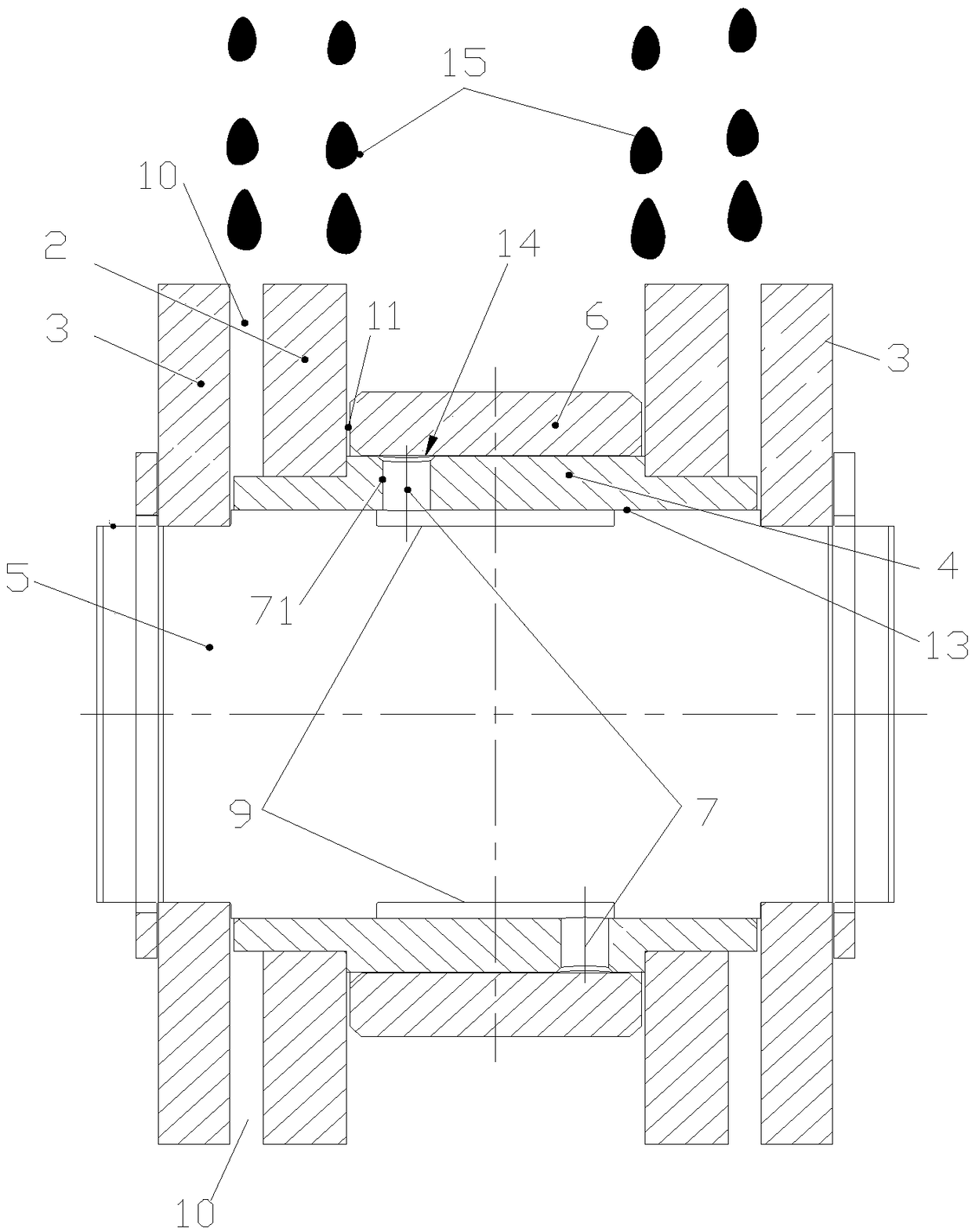

[0019] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

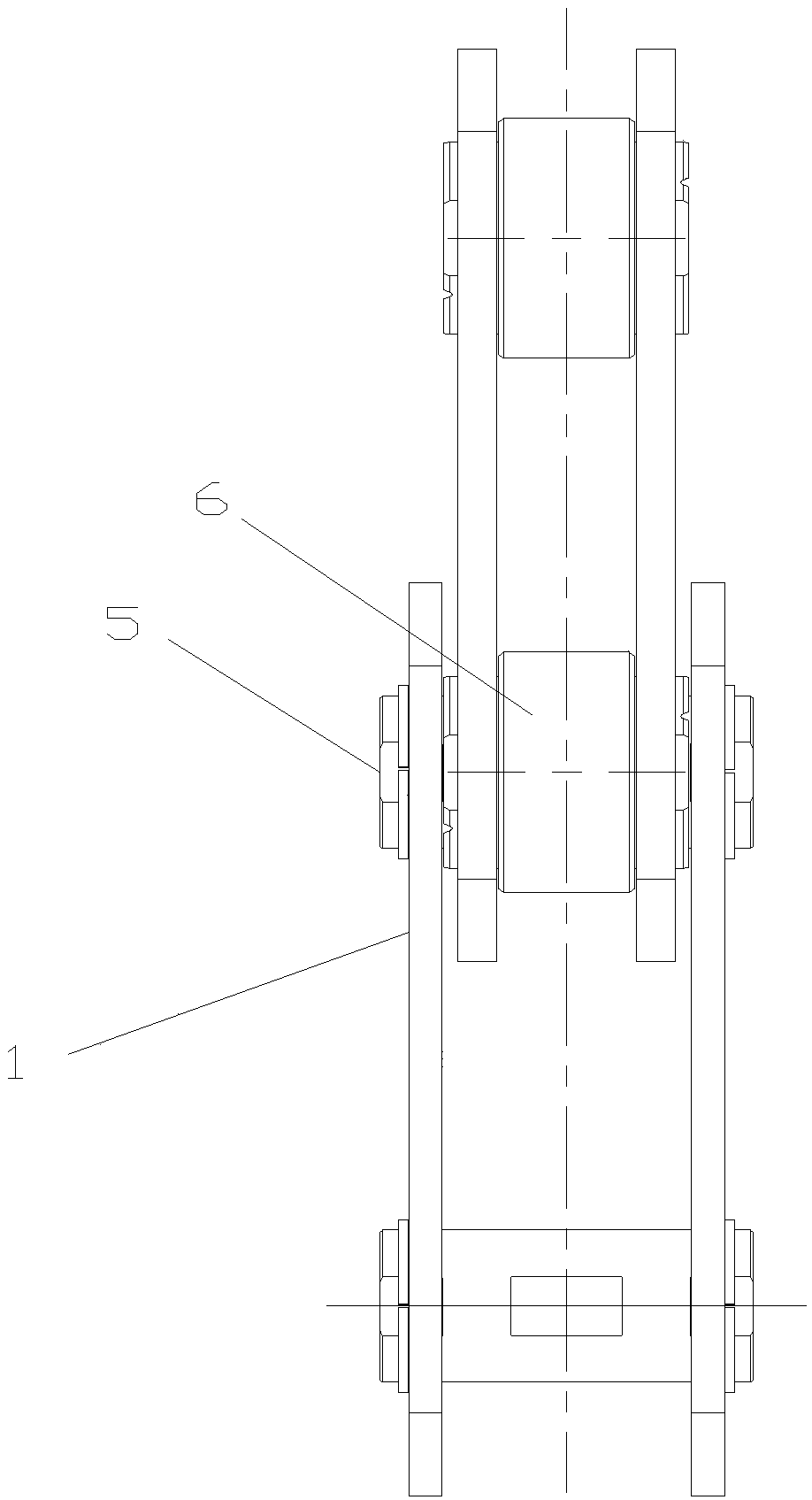

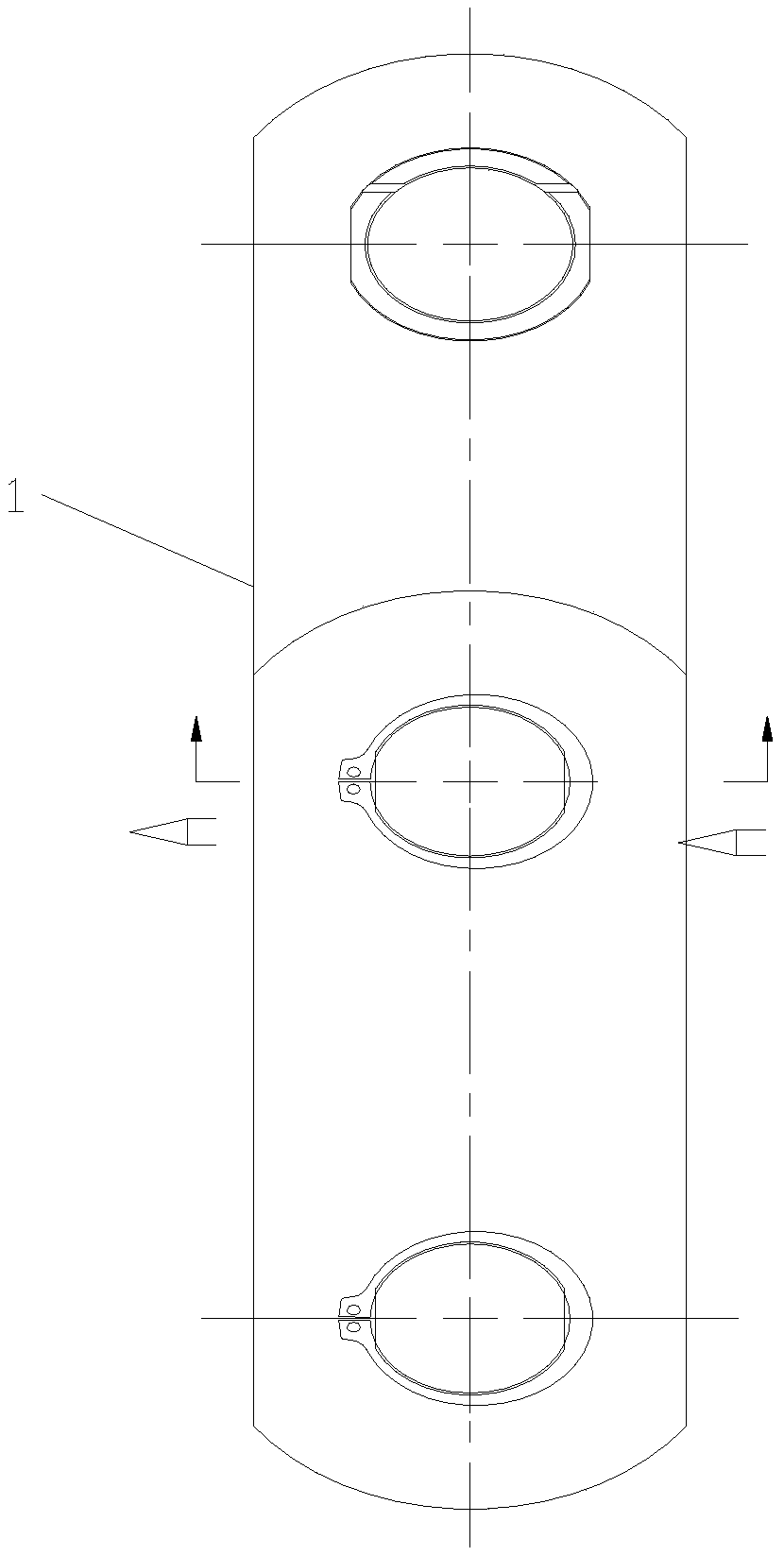

[0020] like Figure 1-5 As shown, a step chain with improved lubrication includes several hinges 1 connected by adjacent links. The hinge 1 includes a pair of inner chain plates 2, a pair of outer chain plates 3, and a sleeve 4 , the pin shaft 5 and the roller 6, the inner link plate 2 is in interference connection with the sleeve 4, the outer link plate 3 is in interference connection with the pin shaft 5, and the pin shaft 5 and the sleeve 4 are clearance-fitted to form a hinge kinematic pair, so The sleeve 4 and the roller 6 are in clearance fit, the inside of the sleeve 4 is provided with oil holes 7 on both sides, and the two ends of the sleeve 4 are provided with grooves 8, and the gap between the inner chain plate 2 and the outer chain plate 3 is There is a first side gap 10, a second side gap 11 is set between the inner chain p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com