Device for filling packaging, in particular bottles or cups, with liquid to pasty food and beverages

A packaged, paste-like technology used in the field of bottle or cup equipment to solve problems such as maintenance, inspection and narrow specification changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

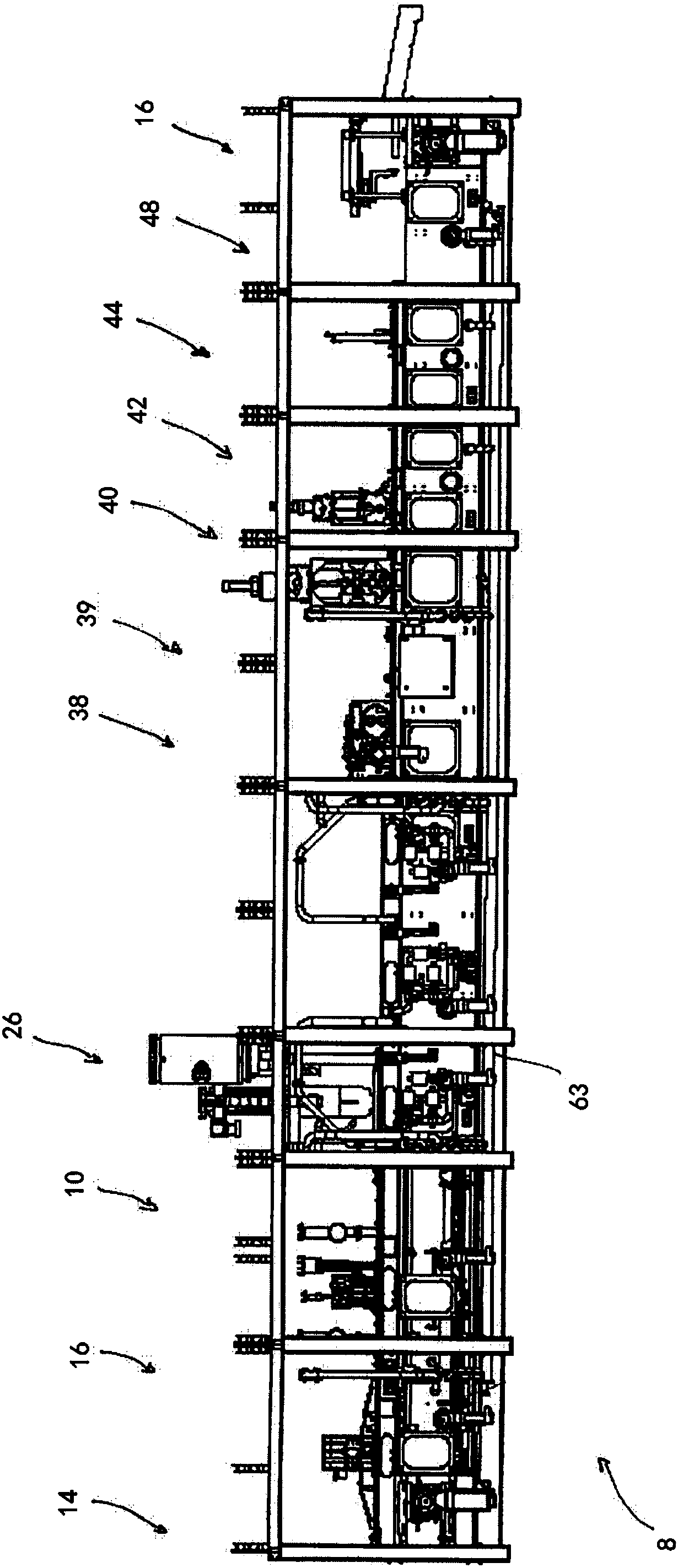

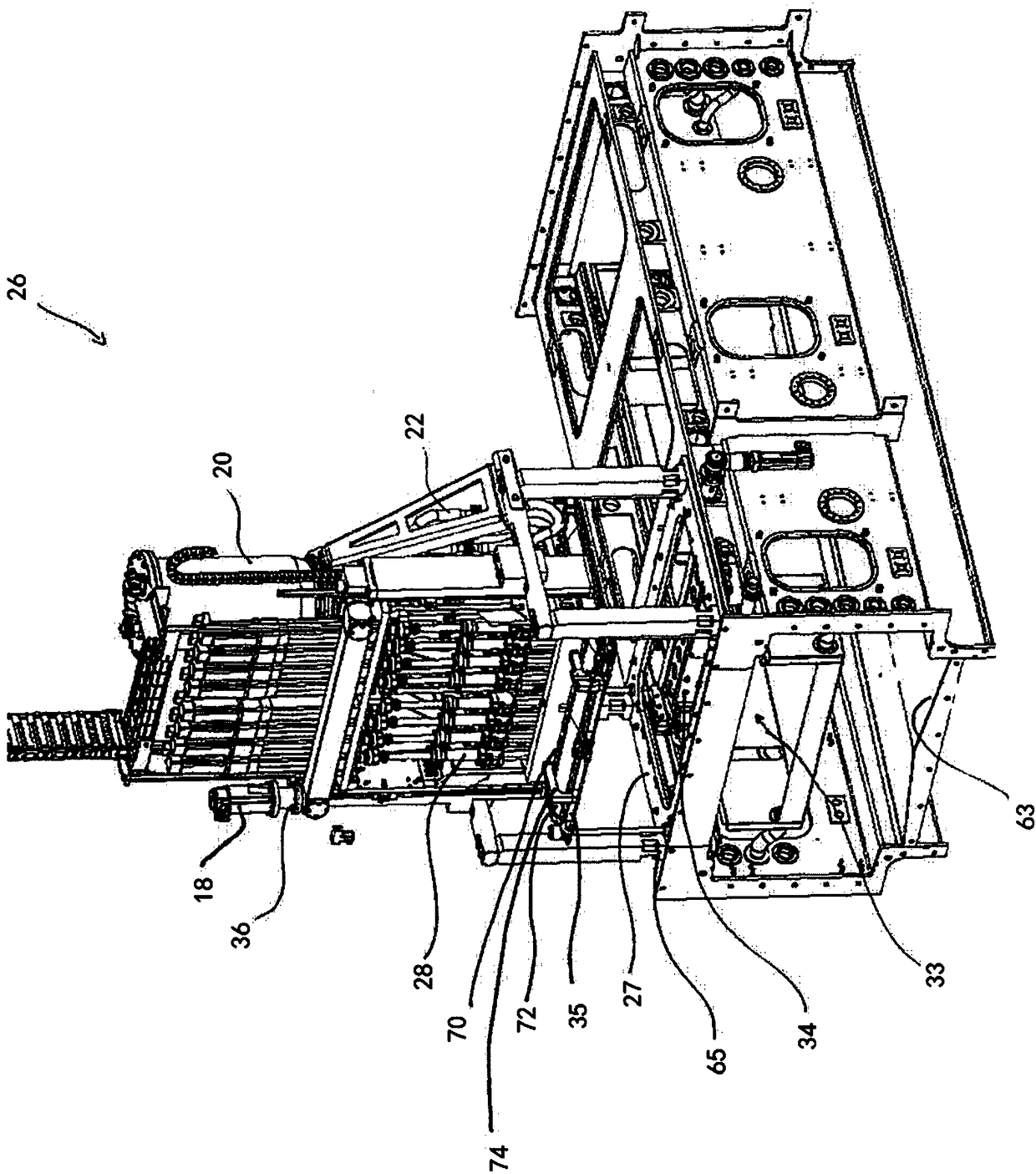

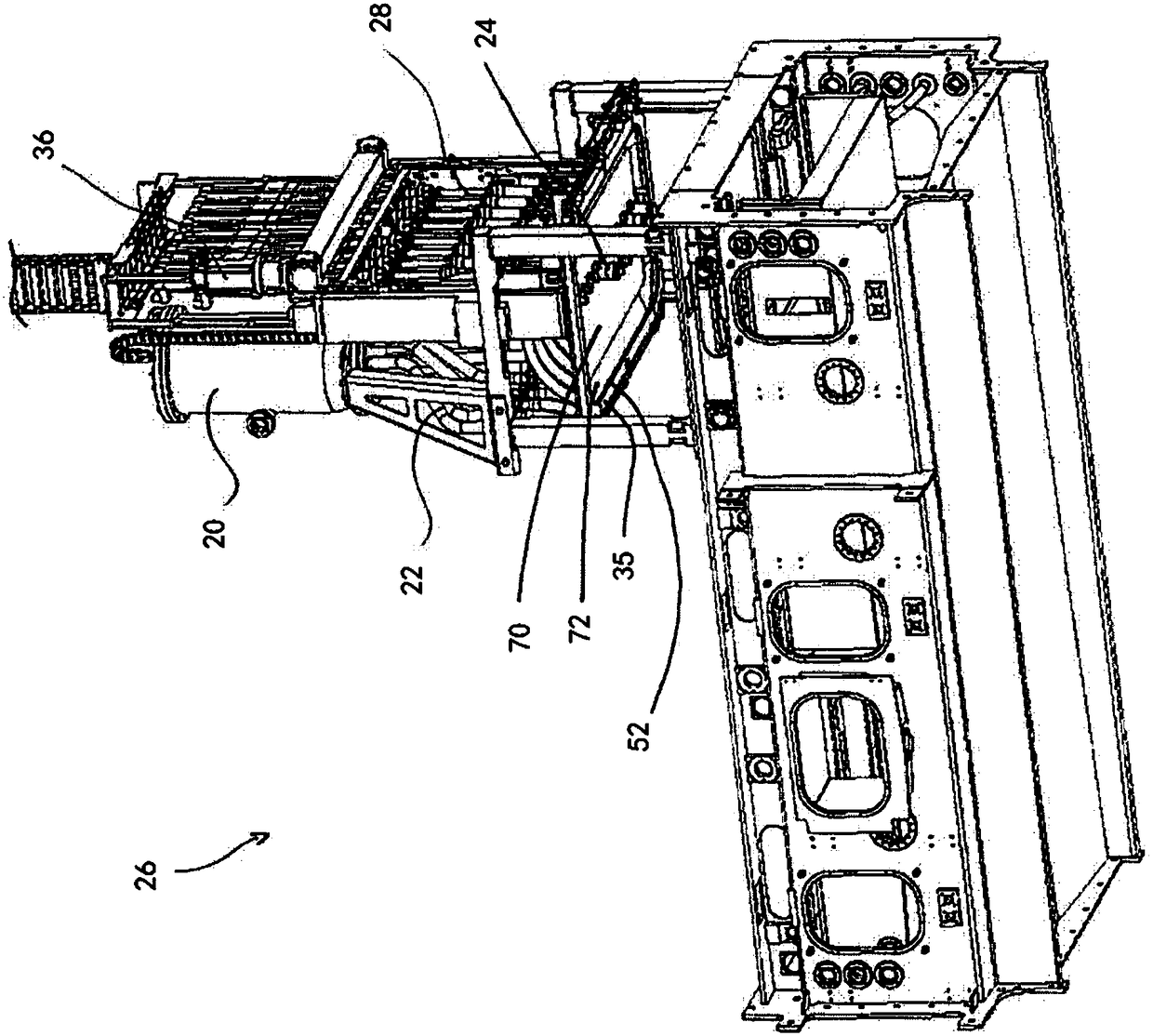

[0020] according to figure 1 The exemplary embodiment of the present invention shows a filling machine 8 or a device 8 for filling packages, in particular bottles or cups, with liquid to pasty food and beverages. Packages such as cups, bottles or the like are supplied to the sterilization module 10 via a package supply. This is an already prefabricated package. In this case, for example, stacks of cups can be automatically inserted into the pack supply device 14 . The package carrier equipped with the packages is moved by a conveyor system to different processing stations, such as a package supply unit, a sterilization unit, a dosing unit, a closing unit, a removal unit, etc. The conveyor system is embodied, for example, as an endless belt or chain. For this purpose, the conveyor system includes, for example, a drive module 16 , which includes, for example, a sprocket or a deflection device. A further drive module 16 for driving or deflecting the conveyor system is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com