Water paint assembly as well as preparation method and application thereof

A water-based paint and package technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of affecting the environment and human health, affecting the health of hot water users, and the protective paint needs to be improved, so as to improve storage stability, Environmental pollution and human health hazards are small, and the paint film dries quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

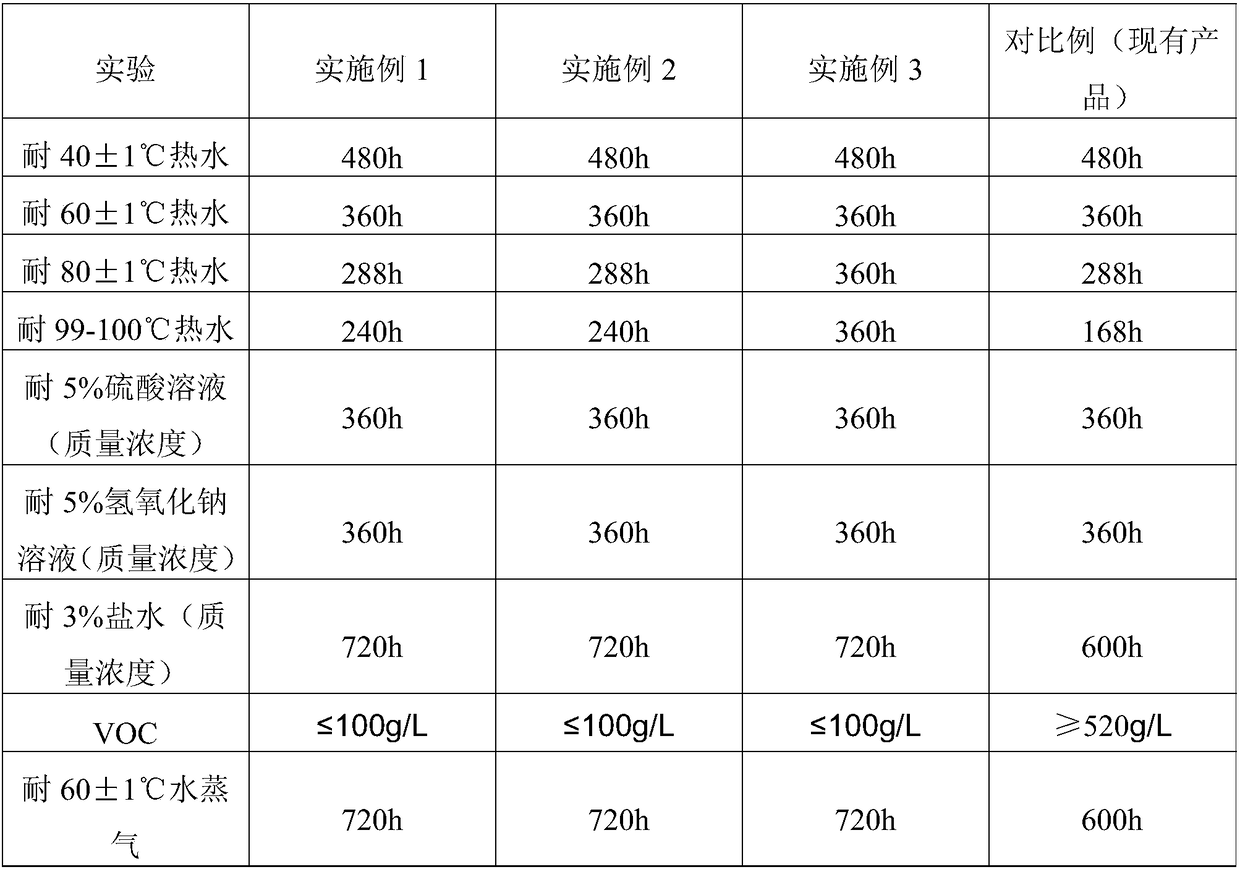

Examples

Embodiment 1

[0088] formula:

[0089] The first water paint component in the water paint kit includes:

[0090] The aqueous epoxy emulsion of 28 parts by weight;

[0091] The water-based acrylic modified epoxy emulsion of 40 parts by weight;

[0092] 3.5 parts by weight of environmentally friendly co-solvent;

[0093] The neutralizing agent of 0.05 weight part;

[0094] The dispersant of 1.5 parts by weight;

[0095] The defoamer of 0.3 parts by weight;

[0096] The substrate wetting agent of 0.2 weight part;

[0097] The anti-settling agent of 0.3 weight part;

[0098] 10 parts by weight of deionized water;

[0099] The thickener of 0.5 weight part;

[0100] 1 part by weight of anti-flash rust agent;

[0101] The rheology agent of 0.5 weight part;

[0102] The coupling agent of 0.8 weight part;

[0103] 0.2 parts by weight of leveling agent;

[0104] 5 parts by weight of rutile titanium dioxide;

[0105] 3 parts by weight of phthalocyanine green; and

[0106] 6 parts by weig...

Embodiment 2

[0125] formula:

[0126] The first water paint component in the water paint kit includes:

[0127] The aqueous epoxy emulsion of 30 parts by weight;

[0128] The water-based acrylic modified epoxy emulsion of 45 parts by weight;

[0129] 4.5 parts by weight of environmentally friendly co-solvent;

[0130] The neutralizing agent of 0.1 weight part;

[0131] 2.0 parts by weight of dispersant;

[0132] The defoamer of 0.5 weight part;

[0133] 0.3 parts by weight of substrate wetting agent;

[0134] The anti-settling agent of 0.38 weight part;

[0135] 14 parts by weight of deionized water;

[0136] The thickener of 1.5 parts by weight;

[0137] The anti-flash rust agent of 1.2 parts by weight;

[0138] The rheological agent of 1.2 parts by weight;

[0139] The coupling agent of 1.2 parts by weight;

[0140] 0.3 parts by weight of leveling agent;

[0141] 5.5 parts by weight of rutile titanium dioxide;

[0142] 3.2 parts by weight of phthalocyanine green; and

[014...

Embodiment 3

[0162] formula:

[0163] The first water paint component in the water paint kit includes:

[0164] The aqueous epoxy emulsion of 29 parts by weight;

[0165] The water-based acrylic modified epoxy emulsion of 43 parts by weight;

[0166] 4 parts by weight of environmentally friendly co-solvent;

[0167] The neutralizing agent of 0.07 weight part;

[0168] The dispersant of 1.8 parts by weight;

[0169] The defoamer of 0.4 weight part;

[0170] 0.25 parts by weight of the substrate wetting agent;

[0171] The anti-settling agent of 0.34 parts by weight;

[0172] 12 parts by weight of deionized water;

[0173] 1 part by weight of thickener;

[0174] The anti-flash rust agent of 1.1 parts by weight;

[0175] 0.9 parts by weight of rheological agent;

[0176] The coupling agent of 1 weight part;

[0177] 0.25 parts by weight of leveling agent;

[0178] The rutile type titanium dioxide of 5.25 parts by weight;

[0179] 3.1 parts by weight of phthalocyanine green; and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap