Vibration roller unmanned driving method applied to hydraulic engineering construction

A technology of unmanned driving and water conservancy engineering, applied in roads, road repairs, roads, etc., can solve the problems of high quality rolling construction, harsh rolling operation conditions, high precision rolling operation, etc., to improve easy maintenance Sexuality, improved control level, and the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

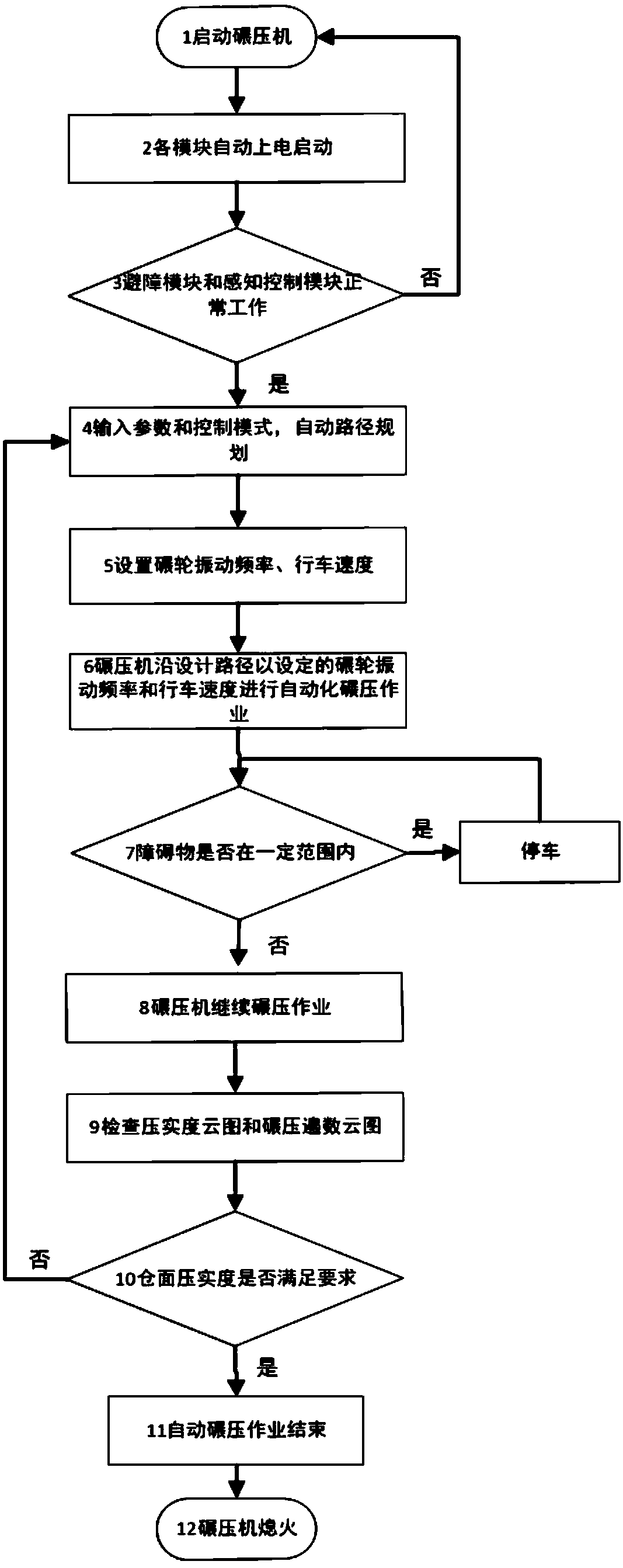

[0051] Example: such as figure 2 As shown, the present invention is applied to the unmanned driving method of the vibratory rolling machine in the construction of water conservancy projects, and specifically includes the following steps when carrying out the construction operation of a warehouse surface:

[0052] 1), the operator manually starts the rolling machine;

[0053] 2), the onboard controller, obstacle avoidance module and perception control module are automatically powered on and started: the power lines of the onboard controller, obstacle avoidance module and perception control module are connected to the onboard power supply of the rolling machine. When the rolling machine is powered on, The onboard controller, obstacle avoidance module and perception control module are automatically powered on and started.

[0054] 3) Observe whether the obstacle avoidance module and the perception control module are working normally through the onboard controller: if there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com