Screw-rod-driven roller bit

A technology of roller cone bit and screw drive, which is applied in the direction of drill bit, driving device for drilling in borehole, drilling equipment, etc. It can solve the problems of bit torque and speed weakening, small fluid displacement, unfavorable rock breaking, etc., to overcome High friction resistance and rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

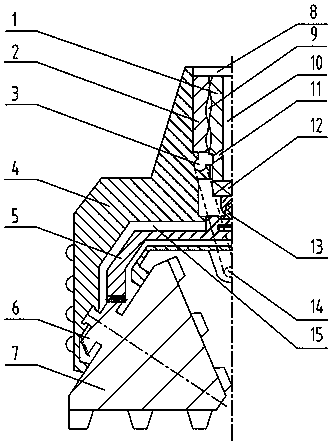

[0022] Refer to attached figure 1 , the screw driven roller cone bit of the present invention comprises a body 4, a roller cone 7, a water inlet 8 and a nozzle 14, a screw power motor is housed in the water inlet 8, and the stator 7 of the screw power motor is embedded in the inner wall of the water inlet 8 Above, the rotor 1 protrudes downwards into the body 4 . A sealed inner cavity 15 is arranged inside the body 4, and a transmission disc 5 is housed in the inner cavity 15, and the transmission disc 5 and the body 4 form a rotating and sealed fit. The rotor 1 is connected with the drive disc 5 through the coupling 12 and the cardan shaft 13 in turn, the upper end of the drive disc 5 is fixedly connected with the cardan shaft 13 to form a shaft drive to transmit torque, and the lower section is provided with teeth. The coupling 12 is a spline structure and transmits torque together with the cardan shaft 13 . There is a driven gear 6 at one end of the cone 7, and the driven...

Embodiment 2

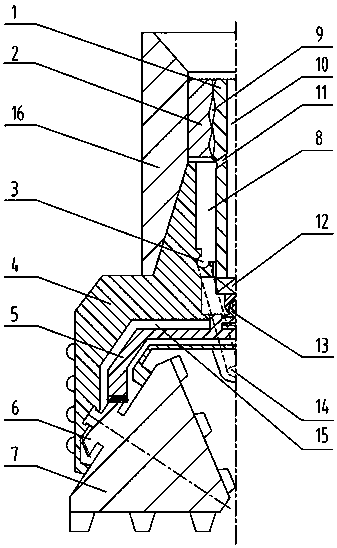

[0025] Another embodiment of the present invention refers to the attached figure 2 , The difference from Embodiment 1 is that the screw joint 16 is threaded above the drill bit, and the stator 2 is installed inside the screw joint 16 . In fact, the runner rubber of the stator 2 is directly vulcanized and molded on the inner wall of the screw nipple 16, and the rotor 1 is installed in the stator 2 and extends downward into the water inlet hole 8 of the drill bit to transmit torque to the drive disc 5. A bypass valve can also be added above the screw pup joint 16 to realize the internal and external pressure balance of the drilling tool when tripping.

[0026] The number of cones in the above-mentioned embodiments is one or more. It can be a single cone bit, a symmetrically arranged double cone bit, or a common three-cone bit. The number of cones can also be more than three.

[0027] The working process of the present invention is as follows: the screw-driven roller cone bit i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap