Tunnel lining trolley with material distribution device

A technology of material distribution device and lining trolley, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve the problems of high labor intensity, low work efficiency, and slow cement conveying speed, and achieve the goal of reducing labor intensity and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

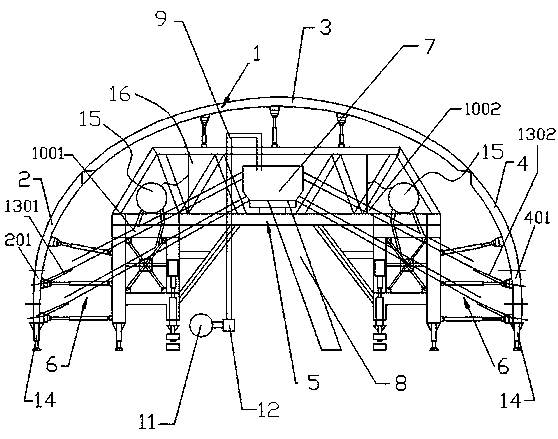

[0016] Attached below figure 1 The present invention is described in further detail.

[0017] as attached figure 1 As shown, the present invention is a tunnel lining trolley with a material distribution device, which includes an arc-shaped formwork unit 1, a skeleton unit 5 and an adjustment support unit 6; The first side template group 2, the top template 3 and the second side template group 4;

[0018] The adjustment support unit 6 is arranged between the skeleton unit 5 and the template unit 1, and is configured to push the first side template group 2, the top template group 3 and the second side template group 4 outward according to the size of the tunnel section. Move to make it stick to the lining of the tunnel; the skeleton unit 5 is equipped with a charging and distributing device 7 with stirring function, and the charging and distributing device 7 is connected with a A cement conveying device 8 for cement and a delivery pipe 9 for delivering water to the charging a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com