Flow control valve

A flow control valve and valve body technology, which is applied in the direction of coolant flow control, valve details, multi-way valve, etc., can solve the problems of poor installation workability and achieve the effect of improving installation workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

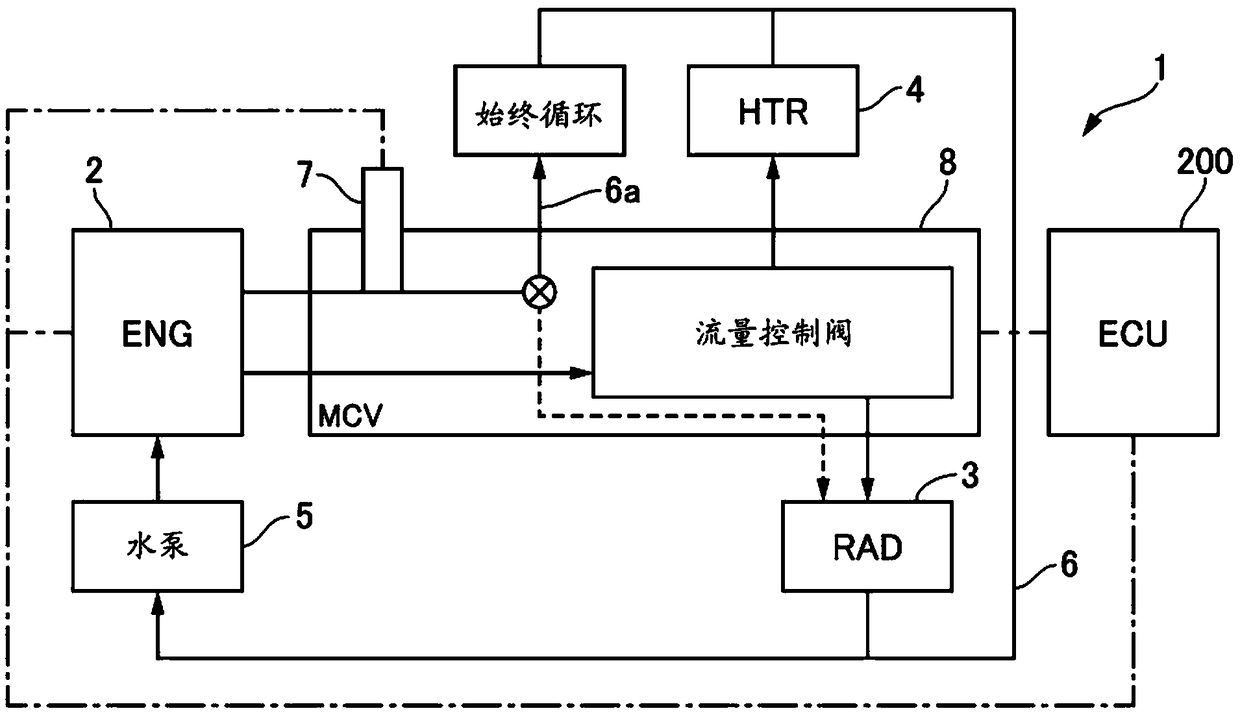

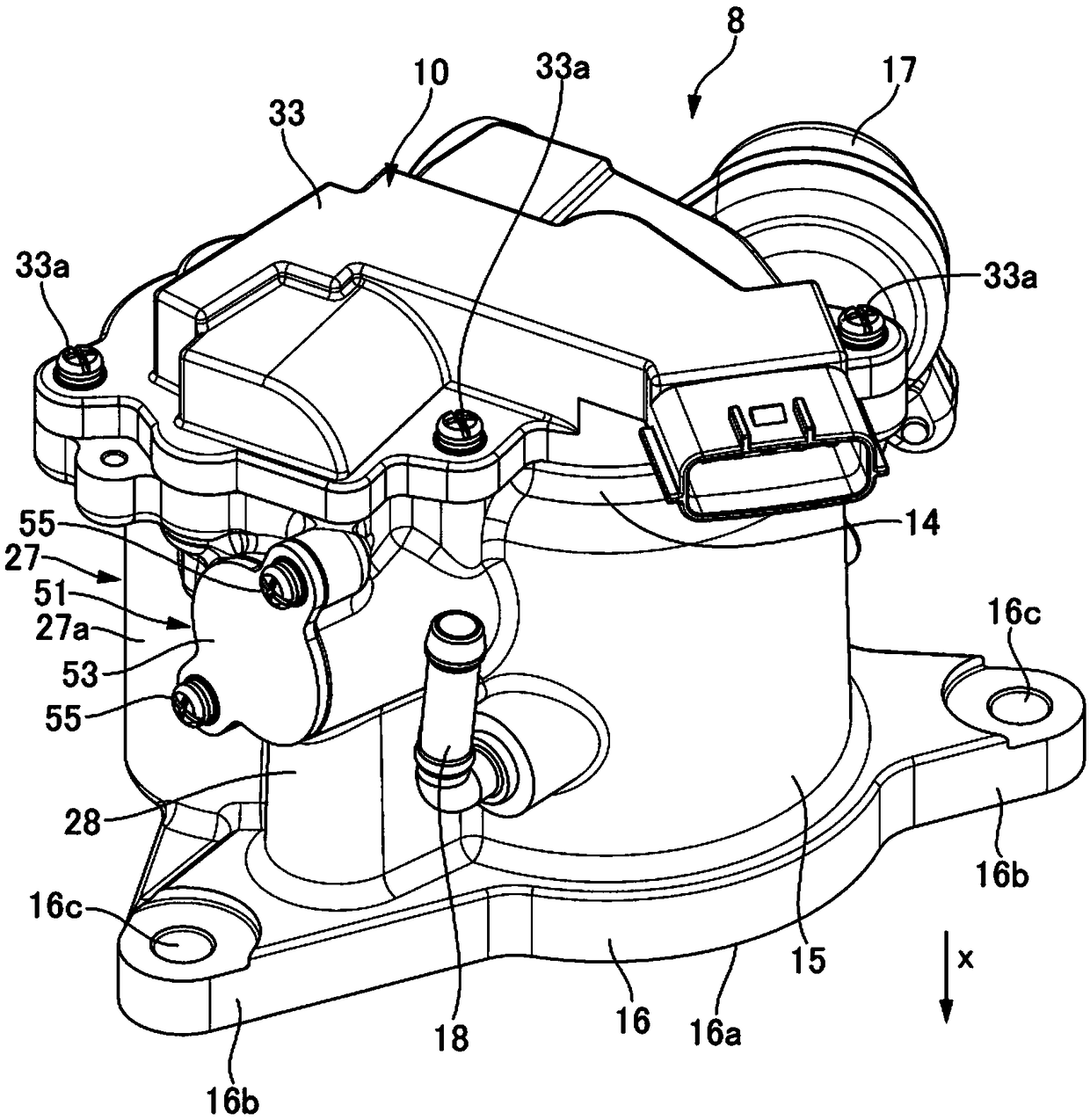

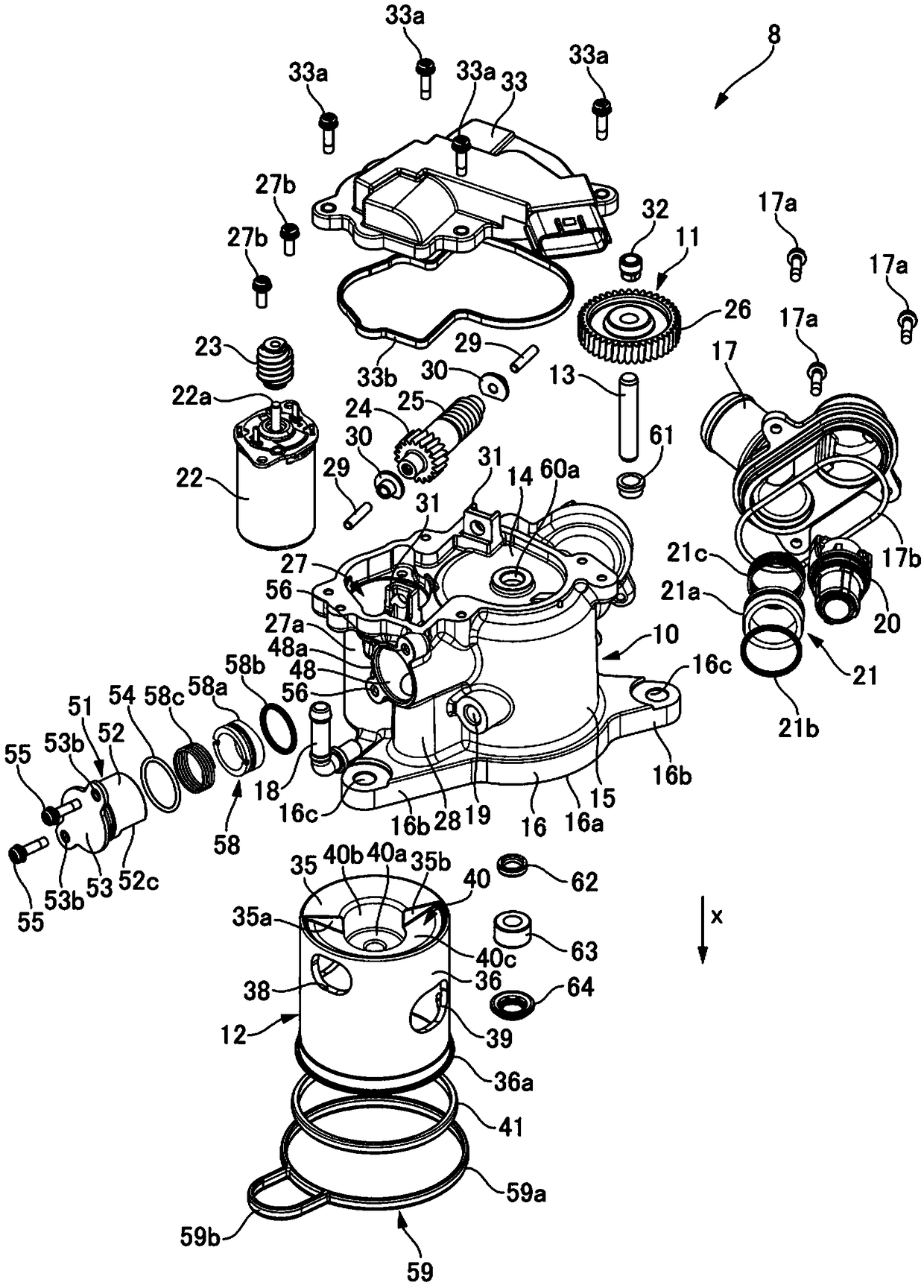

[0033] figure 1 It is a schematic diagram of the cooling system 1 of Embodiment 1.

[0034] The cooling system 1 according to the first embodiment has a circuit 6 for returning the cooling water cooled by the engine 2 as a heat source to the engine 2 via the water pump 5 after passing through a plurality of heat exchangers (radiator 3 and heater 4 ). The engine 2 is, for example, a gasoline engine, and is mounted on a vehicle. The radiator 3 cools the cooling water through heat exchange between the cooling water and the traveling wind. When the heater 4 heats the interior of the vehicle, the cooling water is cooled by heat exchange between the cooling water and the air blown into the vehicle interior. The water pump 5 is rotationally driven by the driving force of the engine 2 and supplies cooling water from the radiator 3 and the heater 4 to the engine 2 . The circuit 6 has a normally open water channel 6a, which bypasses the heat exchangers 3, 4 and is used to circulate t...

Embodiment approach 2

[0072] Next, Embodiment 2 will be described. The basic structure of Embodiment 2 is the same as that of Embodiment 1, so only the parts that differ from Embodiment 1 will be described.

[0073] Figure 8 It represents MCV8 of Embodiment 2 Figure 4 The S6-S6 line view sectional view, Figure 9 It is a front view of the cover 51 of Embodiment 2. In the MCV8 of the second embodiment, the shape of the cover 51 is different from that of the first embodiment. The cover 51 has an R-shaped portion 65 inside it. The R-shaped portion 65 smoothly connects the inner peripheral surface of the cylindrical portion 52 and the inner side surface of the flange portion 53 with a curved surface having a predetermined curvature. The center of curvature of the R-shaped portion 65 is on the inner side of the cover 51 .

[0074] The flange portion 53 of Embodiment 2 has a rotationally asymmetric shape with respect to a point on the central axis O when viewed from the axial direction of the cyl...

Embodiment approach 3

[0079] Next, Embodiment 3 will be described. The basic structure of Embodiment 3 is the same as that of Embodiment 1, so only the parts that differ from Embodiment 1 will be described.

[0080] Figure 10 It represents MCV8 of Embodiment 3 Figure 4 The S6-S6 line view sectional view. The MCV 8 according to Embodiment 3 differs from Embodiment 1 in that the gap between the second opening 38 and the internal communication port 50 is not sealed. Specifically, MCV8 of Embodiment 3 does not have figure 1 and Image 6 The sealing member 58 shown in. Accordingly, cost reduction can be achieved by reducing the number of components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com