A defect detection method and device

A detection method and defect technology, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of low accuracy of detection methods, and achieve the effect of solving low accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

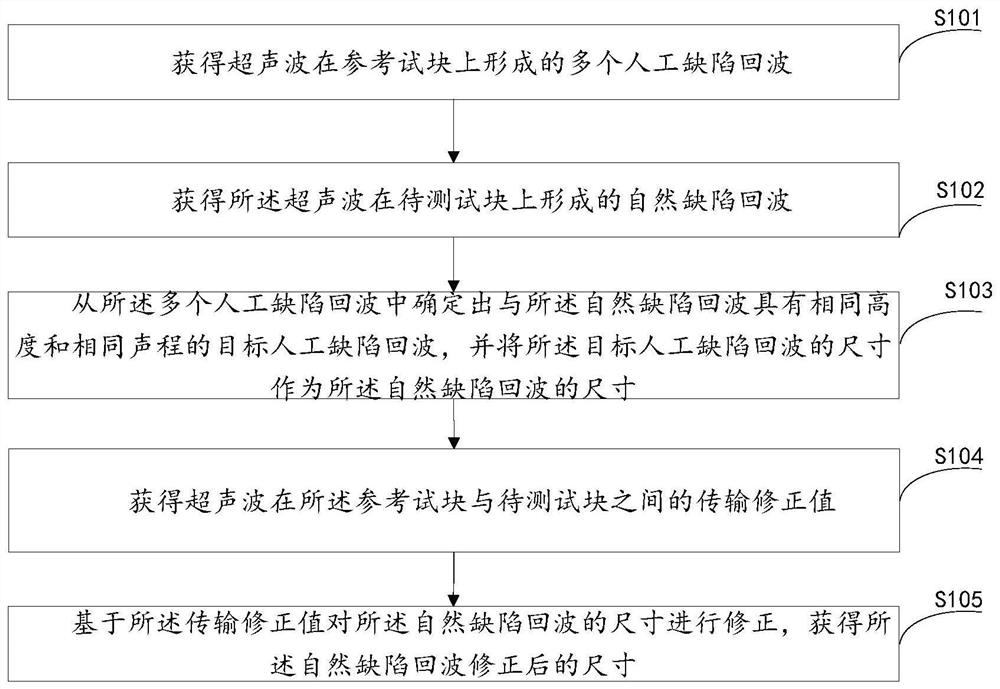

[0091] This embodiment provides a defect detection method, such as figure 1 As shown, the method includes:

[0092] First, step S101 is executed: multiple artificial defect echoes formed by ultrasonic waves on the reference test block are obtained.

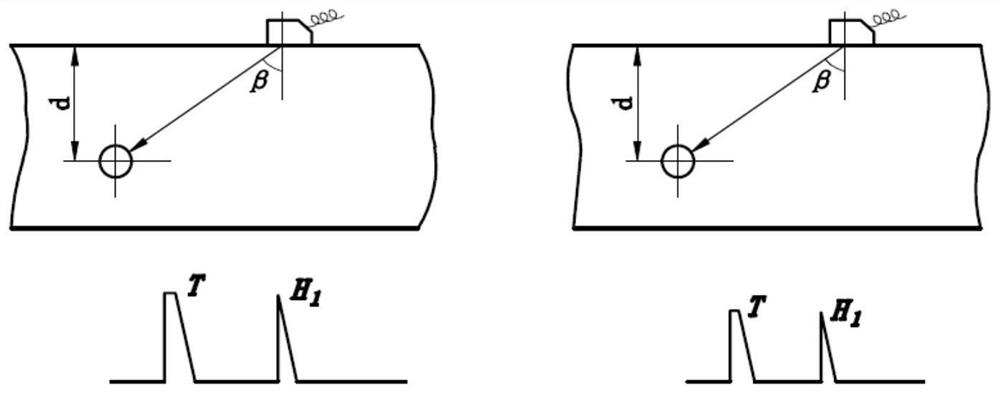

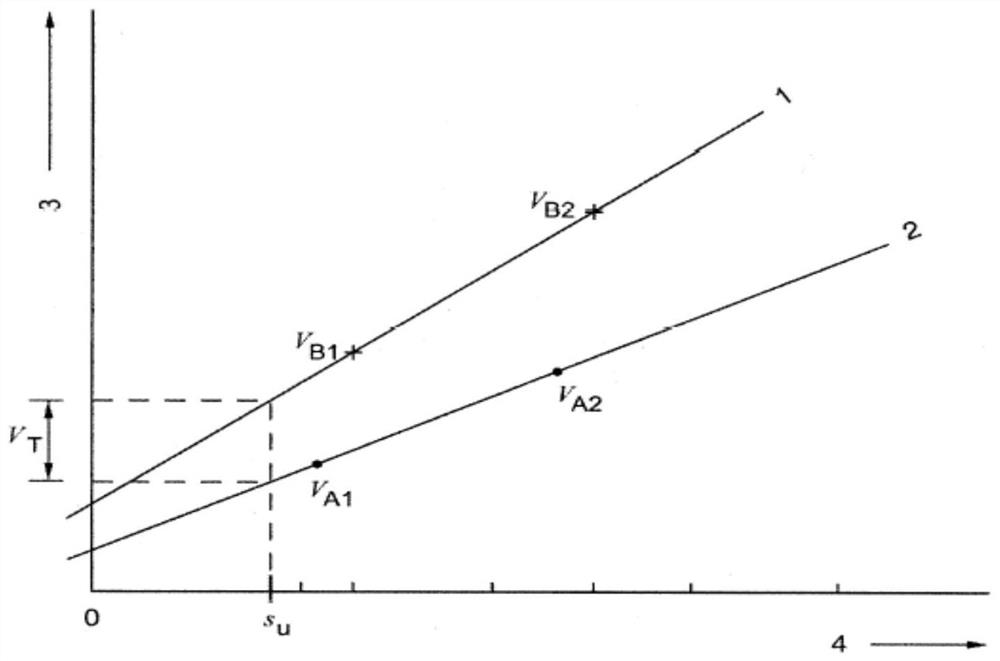

[0093] Specifically, ultrasound is a sound wave with a frequency higher than 20,000 Hz. It has good directionality and strong penetrating ability. The lower limit of ultrasonic frequency is greater than the upper limit of human hearing. Ultrasonic testing is an important testing method in the field of nondestructive testing. In a specific implementation process, the defect echo can be obtained by reflecting the pulse emitted by the ultrasonic probe in the reference test block, wherein the artificial defect can be obtained by machine processing or manual production. Multiple artificial flaw echoes can be obtained on one reference test block or on different reference test blocks. In order to facilitate detection, different artifi...

Embodiment 3

[0189] Based on the same inventive concept, Embodiment 3 of the present invention provides a computer-readable storage medium 500, please refer to Figure 5 , on which a computer program 511 is stored, and the method in Embodiment 1 is implemented when the program is executed.

[0190] For example, the above program is configured to perform the following steps:

[0191] Obtain multiple artificial defect echoes formed by ultrasonic waves on the reference test block;

[0192] Obtaining the natural defect echo formed by the ultrasonic wave on the block to be tested;

[0193] A target artificial defect echo having the same height and the same sound path as the natural defect echo is determined from the plurality of artificial defect echoes, and the size of the target artificial defect echo is used as the natural defect echo the size of the wave;

[0194] obtaining a transmission correction value of the ultrasonic wave between the reference test block and the block to be tested;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com