A kind of oxidized dumet silk and its forming processing method

A forming and processing technology, applied in electrical components, cable/conductor manufacturing, heat treatment equipment, etc., can solve problems such as environmental pollution, poor surface boron layer firmness, affecting product quality, etc., to avoid environmental pollution problems, Improves stable uniformity and avoids burnout or leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

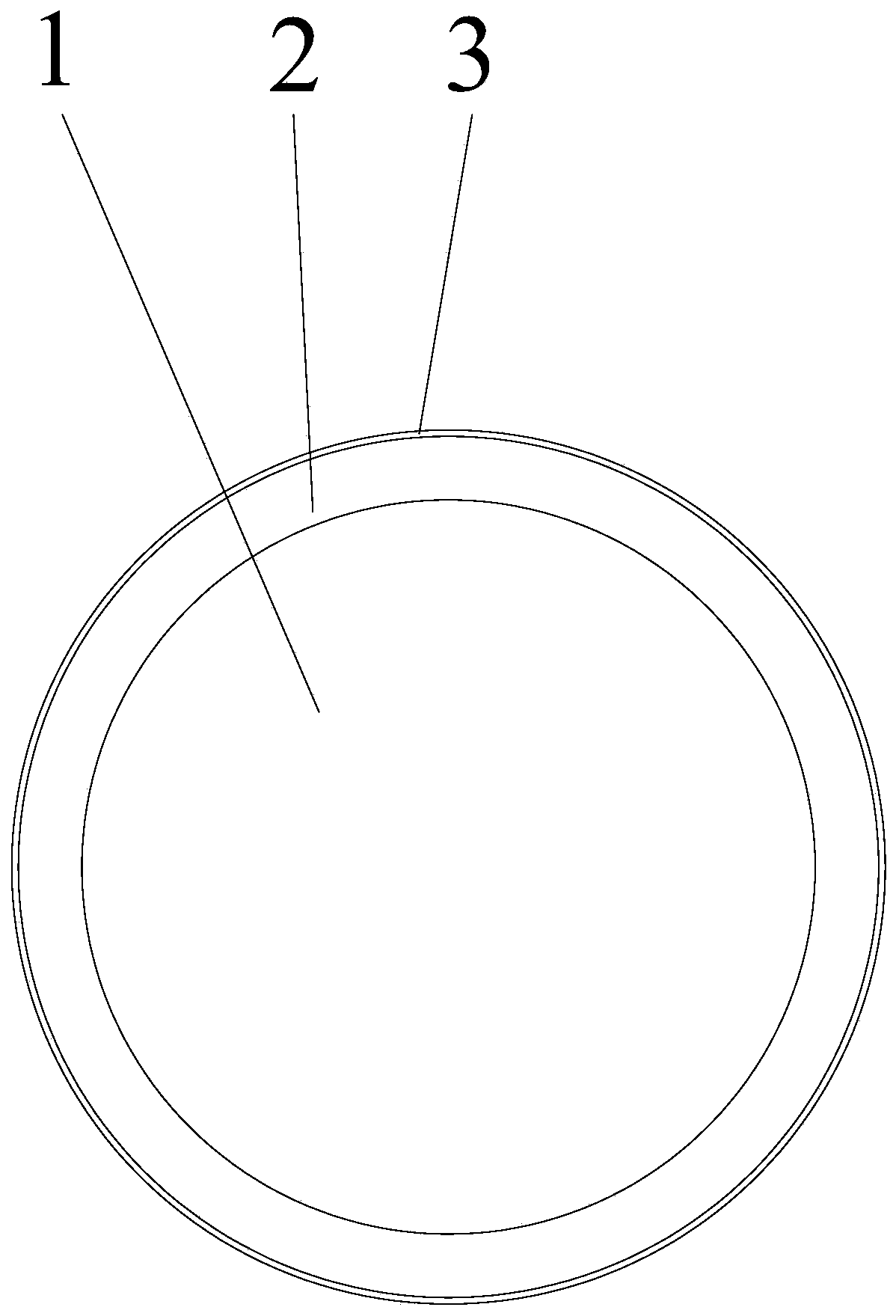

[0039] As shown in the figure, the present invention provides an oxidized Dumet wire, which includes a nickel-iron alloy core wire and a copper clad layer wrapped on the outside of the nickel-iron alloy core wire, a cuprous oxide layer is arranged outside the copper clad layer, and the copper clad layer is The thickness of the layer is 1 / 8 to 1 / 7 times the diameter of the nickel-iron alloy core wire. The preferred thickness of a single layer of copper clad layer is 0.125 times the diameter of the nickel-iron alloy core wire. The cuprous oxide layer is used for glass in the semiconductor industry. Capacitor mosaic in the sealed diode and the circuit board can be effectively sealed with the heated glass to achieve the sealing effect; the oxidized Dumet silk contains 30-32% Ni content and 16.8% Co content ~17.8%, the total amount of trace elements <0.1%, the Cu content is 18%~22%, and the rest is Fe element.

[0040] In this embodiment, nickel-iron-cobalt alloy is preferably used...

Embodiment 2

[0042] As shown in the figure, the present invention provides an oxidized Dumet wire, which includes a nickel-iron alloy core wire and a copper clad layer wrapped on the outside of the nickel-iron alloy core wire. For the cuprous oxide layer, the single layer thickness of the copper clad layer is 1 / 8 to 1 / 7 times the diameter of the nickel-iron alloy core wire. The preferred thickness of the single layer of the copper clad layer is 0.125 times the diameter of the nickel-iron alloy core wire. The copper layer is used in the glass-encapsulated diode in the semiconductor industry and the capacitance inlay of the circuit board. It can be effectively sealed with the heated glass to achieve the sealing effect; the oxidized Dumet silk component contains, Ni The content is 40-42%, the total amount of trace elements is <0.1%, the Cu content is 22-24%, and the rest is Fe element.

[0043] In this embodiment, nickel-iron alloy is used as the wire core material, and the Dumet wire formed ...

Embodiment 3

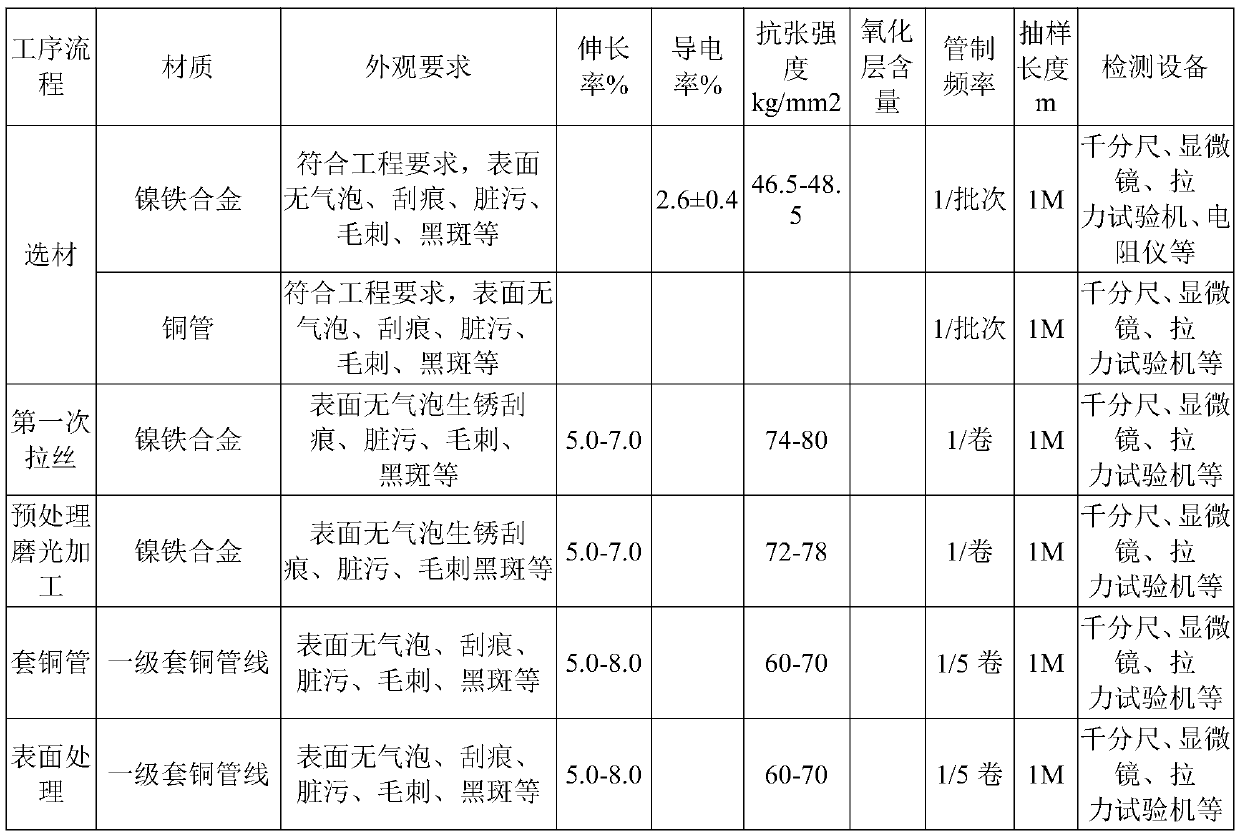

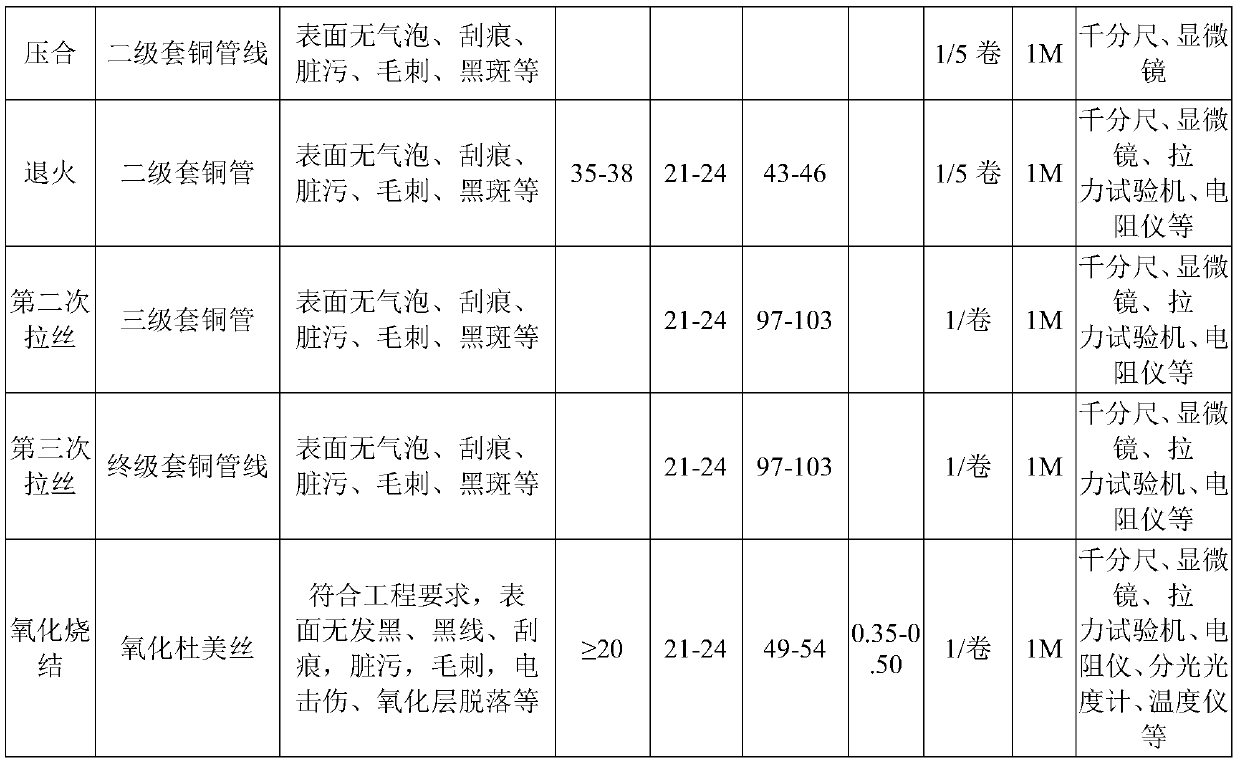

[0045] Based on embodiment 1 or 2, for preparing the oxidized dumet silk in embodiment 1 or 2, its manufacturing process is, comprises the following steps:

[0046] Step 1, material selection, select nickel-iron alloy rods and copper tubes made of nickel-iron alloy materials; carry out surface cleaning treatment on the nickel-iron alloy rods, including deoxidation, deburring and stain cleaning, and then dry; the nickel-iron alloy rods Meet the processing requirements, no bubbles, scratches, dirt, burrs, black spots, etc. on the surface; copper tubes meet the processing requirements, no bubbles, scratches, dirt, burrs, black spots, etc. on the surface; copper tubes meet the processing requirements, no bubbles on the surface , scratches, dirt, burrs, black spots, etc.; the surface of the copper tube meets the processing requirements without bubbles, scratches, dirt, burrs, black spots, etc.;

[0047] Step 2, the first wire drawing, using a wire drawing machine to thin the nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com