Power grid layout structure and system based on ice-melting function

A technology for arranging structure and melting ice, which is applied in the installation of electrical components, cables, overhead installation, etc. It can solve the problems of short ice melting distance, on-site icing, and long time consumption, so as to extend the ice melting distance and reduce the circuit impedance. , the effect of increasing the ice melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

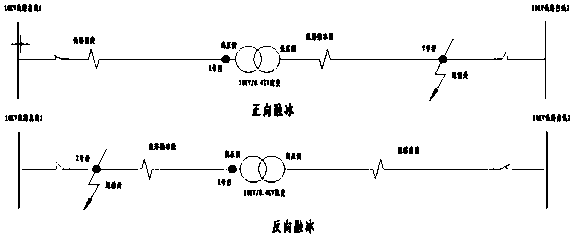

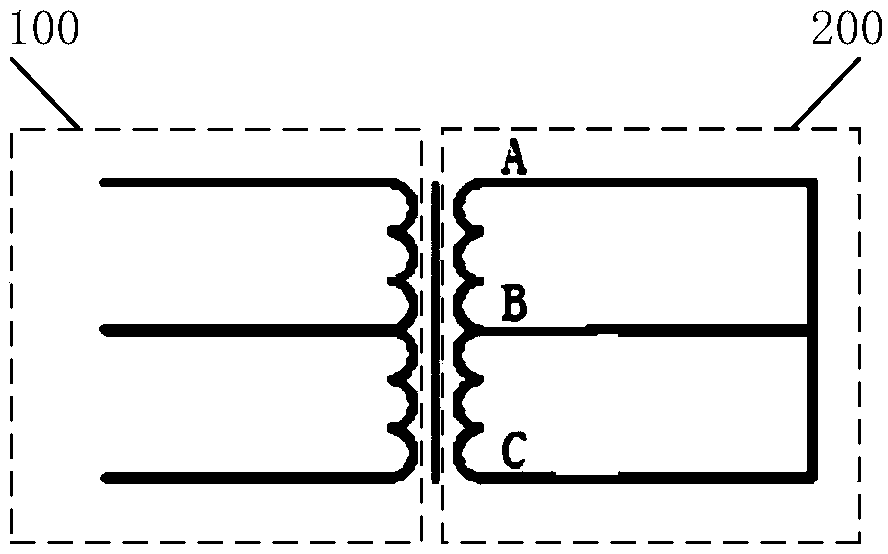

[0046] In the embodiment of the present invention, the voltage on the non-ice-melting side of the transformer is the voltage that provides the ice-melting power supply, and the ice-melting side provides the ice-melting voltage. Here, what affects the ice-melting distance is the ice-melting voltage on the ice-melting side. However, it should be noted that the non-ice-melting side actually only represents the input side of electric energy, and the ice-melting side is the output side of the power supply. In practical applications, the non-ice-melting side can also be used as the ice-melting side, or the ice-melting side The side is the ice-melting side, that is, the ice-melting side can be either the primary side of the transformer or the secondary side of the transformer. For the convenience of expression and understanding, the embodiment of the present invention uses the ice-melting side as one end of the output ice-melting voltage to melt the ice.

[0047] The grid layout stru...

Embodiment 2

[0068] refer to Figure 5 As shown, the 10kv / 0.4kv distribution transformer is used as the ice melting transformer, 0.4kv is the ice melting voltage, the ice melting wire is LGJ-70, the wire impedance is 0.587Ω / km, the distribution transformer capacity is 200KVA, and the three-phase direct short circuit is full load Melting ice, the melting distance is 1.36km, the principle is as follows Figure 8 shown.

[0069] The power grid layout system based on the ice melting function of the present invention includes the power grid layout structure based on the ice melting function as described above, and also includes:

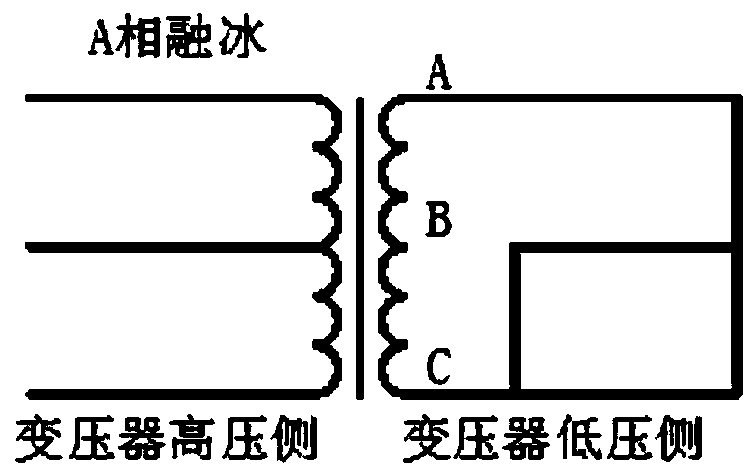

[0070] The transformer's A-phase ice-melting side line, B-phase ice-melting side line and C-phase ice-melting side line are switched in turn and connected in parallel to reduce the total impedance of the circuit, so as to extend the ice-melting distance of the wire by 1.33 times, and the ice-melting distance is extended from the original 1.36km to 1.8km, the princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com