Stable-control load shedding method based on electrolytic aluminum control characteristics

A technology of controlling characteristics and load shedding, which is applied in the direction of climate sustainability, AC network voltage adjustment, power network operating system integration, etc., and can solve problems such as high power supply reliability requirements, safety accidents, and affecting grid flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

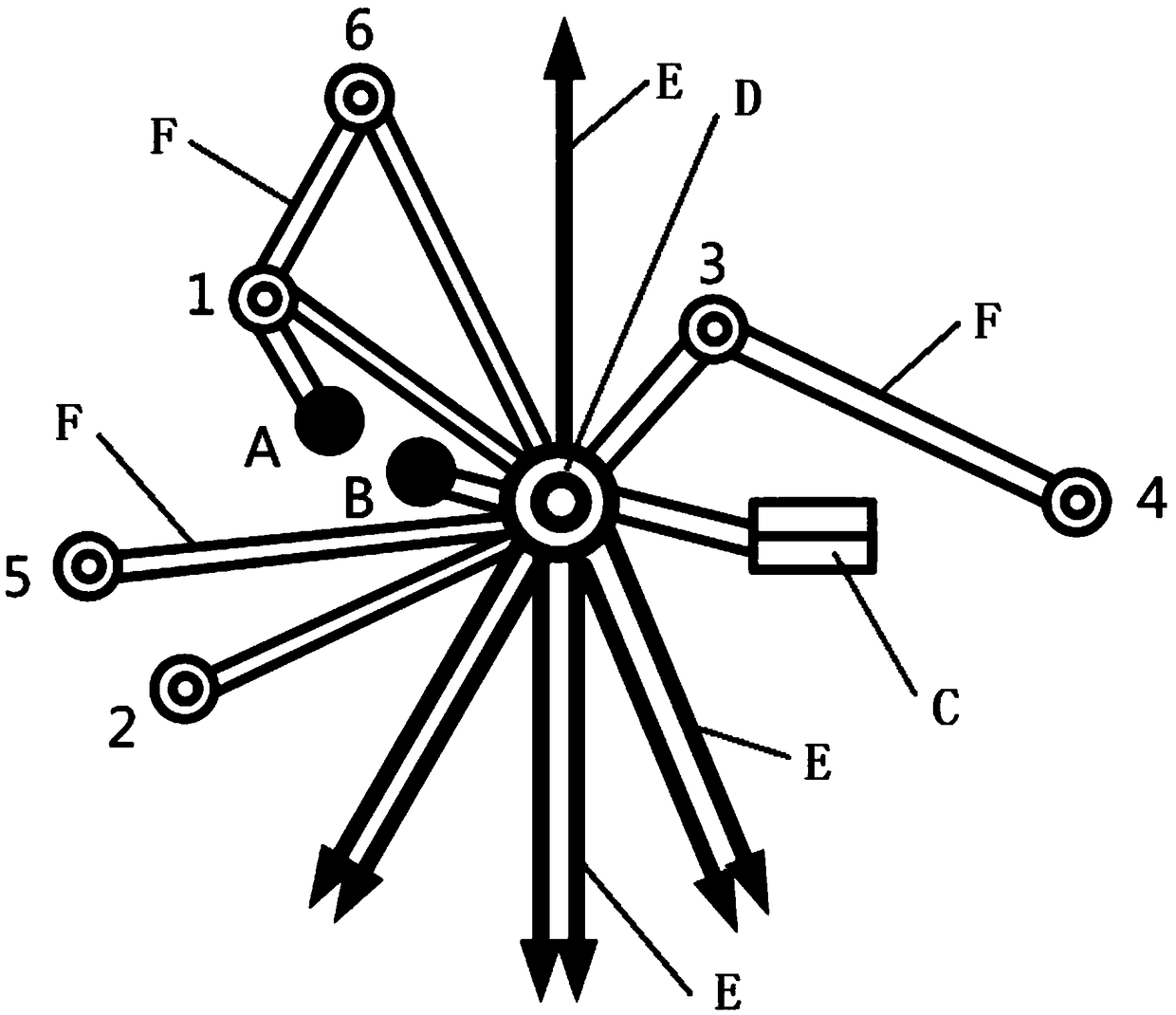

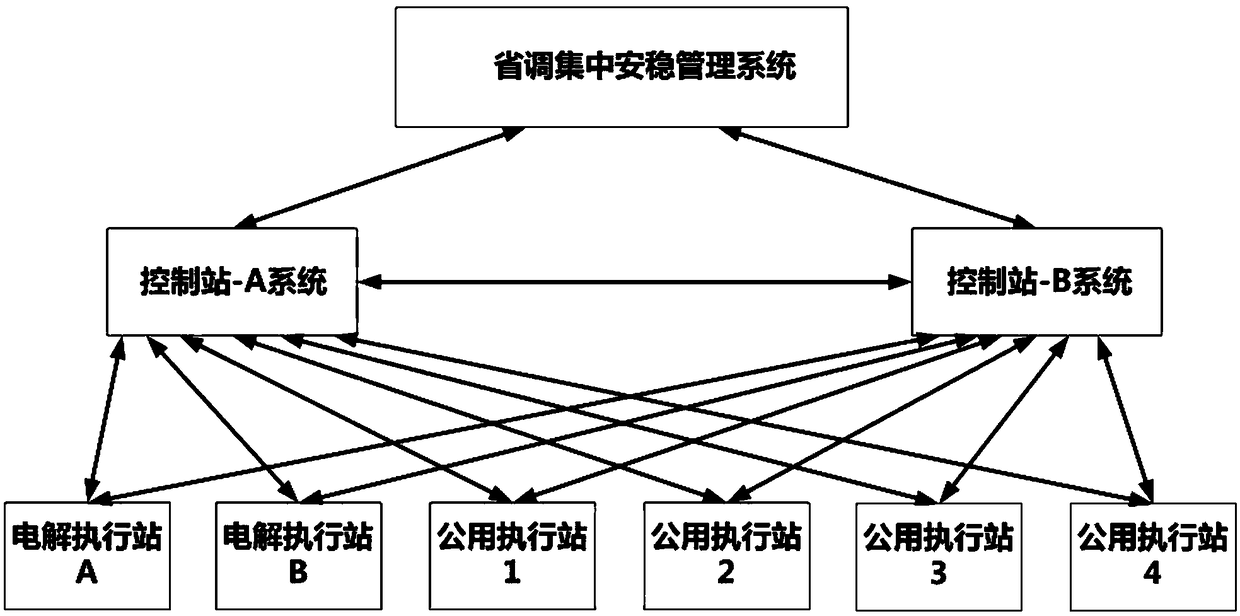

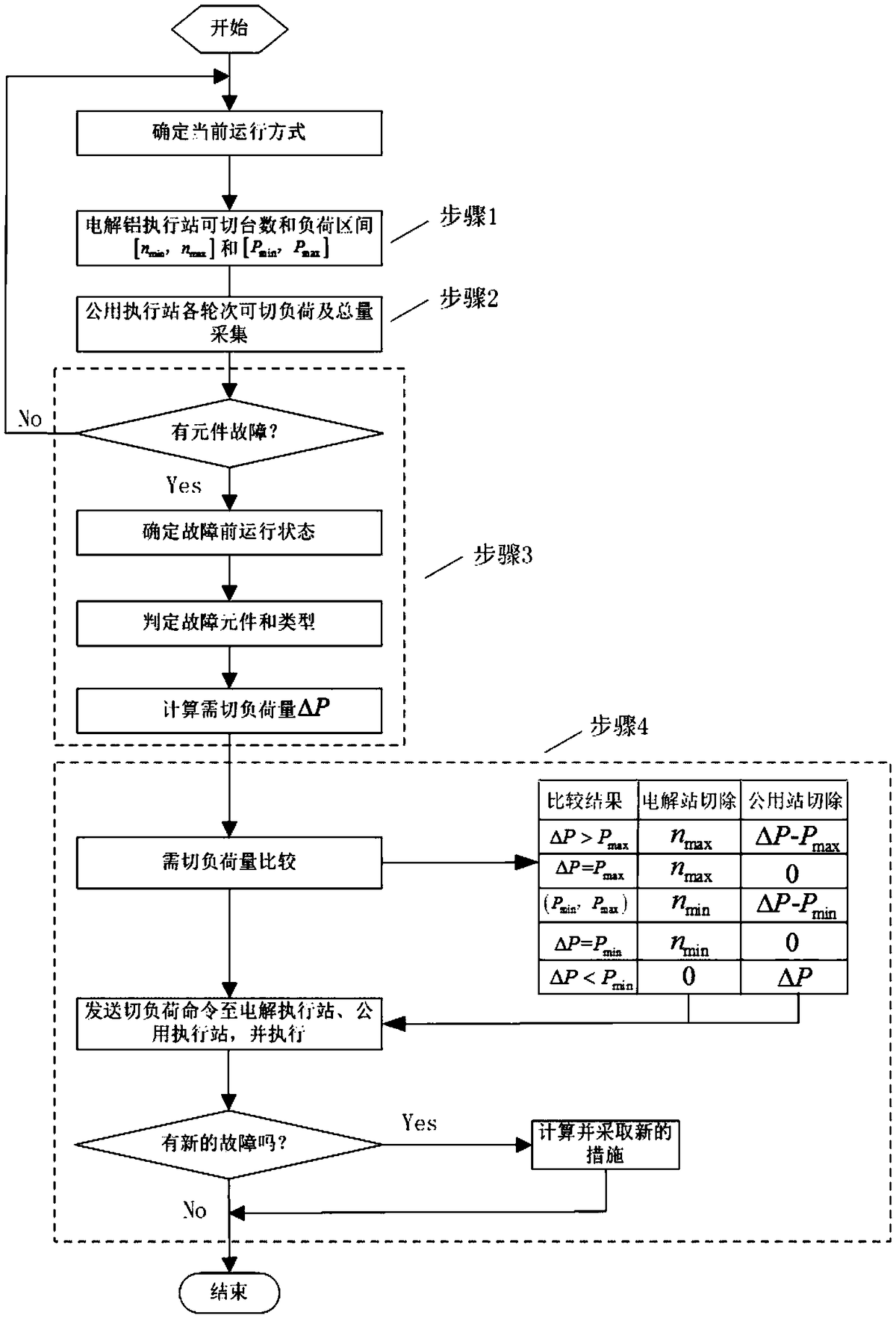

[0062] An embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiment of the present invention to explain the principle of the present invention.

[0063] The invention discloses a stable control load shedding method based on the control characteristics of electrolytic aluminum, which is characterized in that the method includes the following steps:

[0064] Step 1: Calculation of the interval of the number of rectifier units that can be removed by the electrolysis execution station and the interval of the load that can be shed;

[0065] Step 2: The load shedding and total amount collection of each round of the public execution station;

[0066] Step 3: Detect whether there is a component failure and calculate the total load to be shed;

[0067] Step 4: Compare the total amount of load that needs to be she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com