A forward series control system and method for three DC motors

A DC motor, series control technology, applied in the control system, motor speed or torque control, electrical components, etc., can solve the problems of imperfect performance, many functional modules, expensive prices, etc., to save costs and improve Economical, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

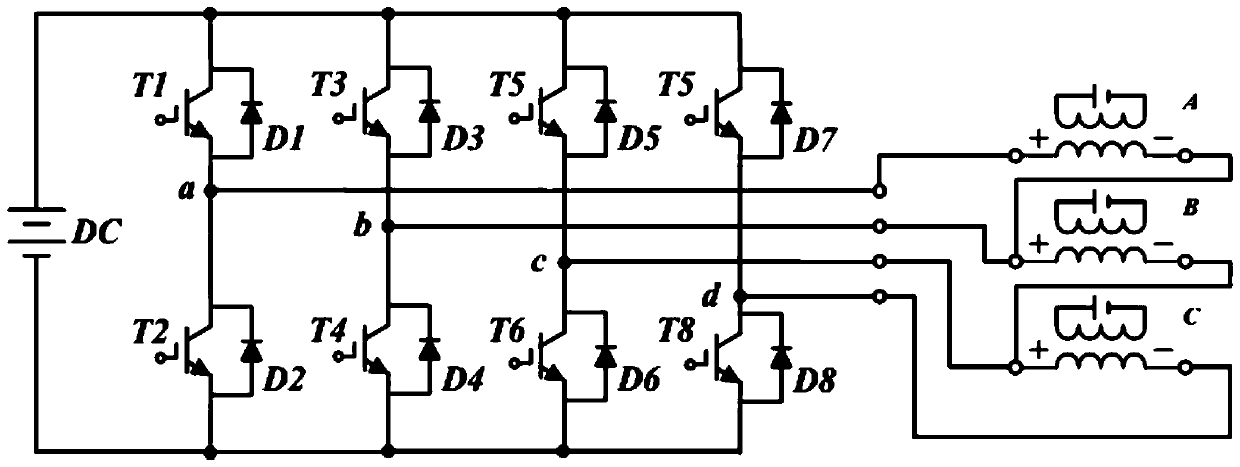

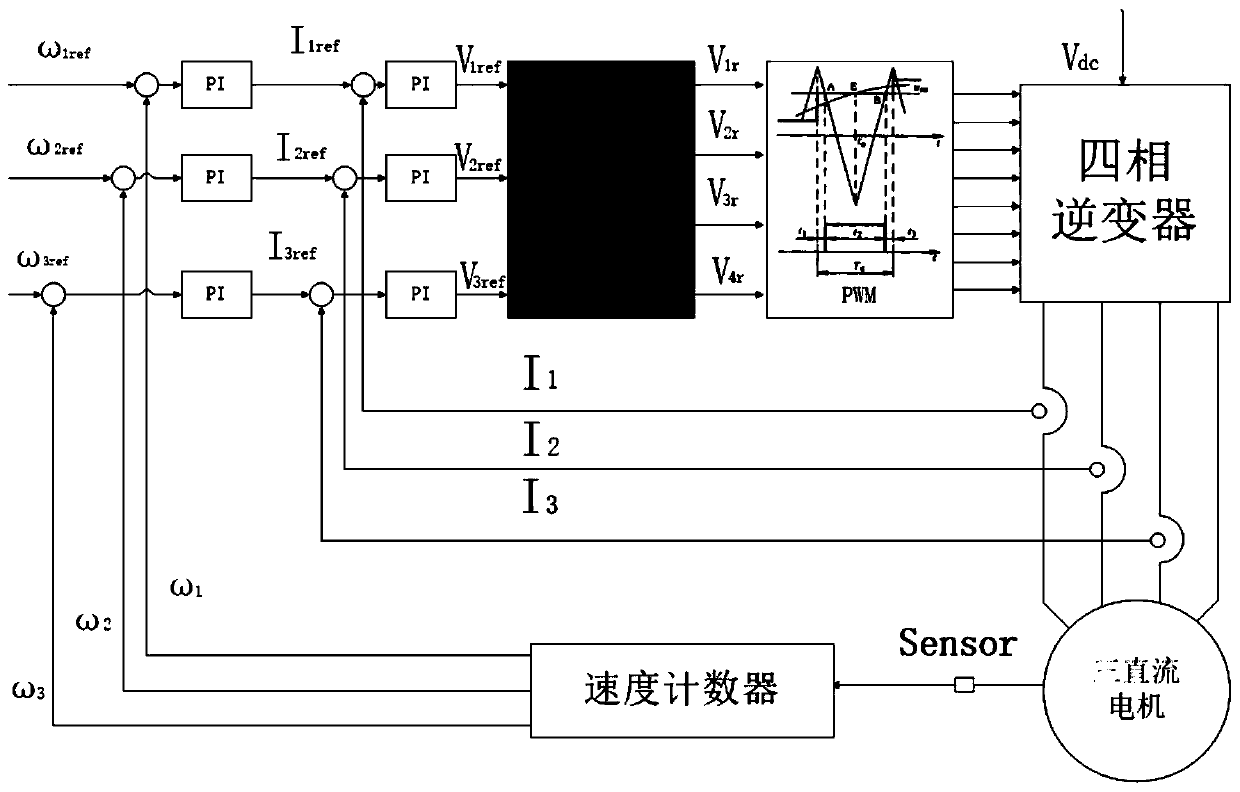

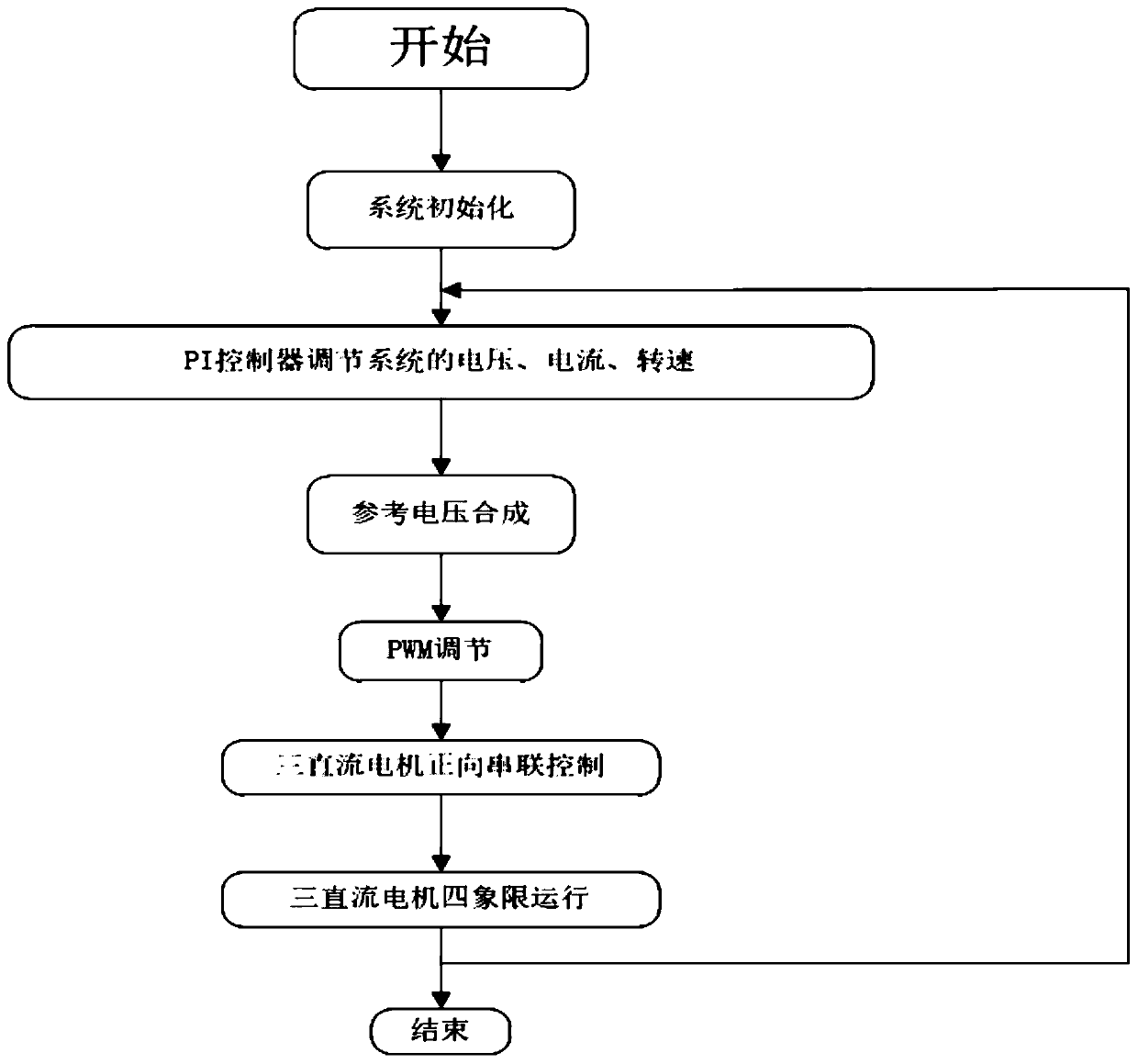

[0044] see figure 1 , a forward series control system of three DC motors in the present invention, three DC motors are forwardly connected in series, the voltages of the three DC motors are adjusted in a steady state, the voltage is synthesized in a reference voltage synthesizer, and the output voltage waveform Perform PWM pulse adjustment to obtain PWM duty cycle, compare the DC motor operating voltage with the size of the DC power supply, and realize the four-quadrant control of the three DC motors.

[0045] Including 8 IGBT modules, DC power supply, three DC motors A, B, C, and 8 IGBT modules, which are connected in series in pairs to form four bridge arms connected in parallel at both ends of the DC power supply, and three DC motors A, B , C pass through the corresponding coupled inductance element in turn through the speed sensor, current sensor and speed adjustment module, and then respectively through the two-stage PI controller and the reference voltage synthesizer, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com