Dust protection device for oil paint production

A protective device and dust protection technology, which is applied in the direction of dust removal, liquid separation agent, cleaning method and utensils, etc., can solve problems such as single function, unfavorable lung health, and insufficient dust protection device, so as to achieve the effect of protecting physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

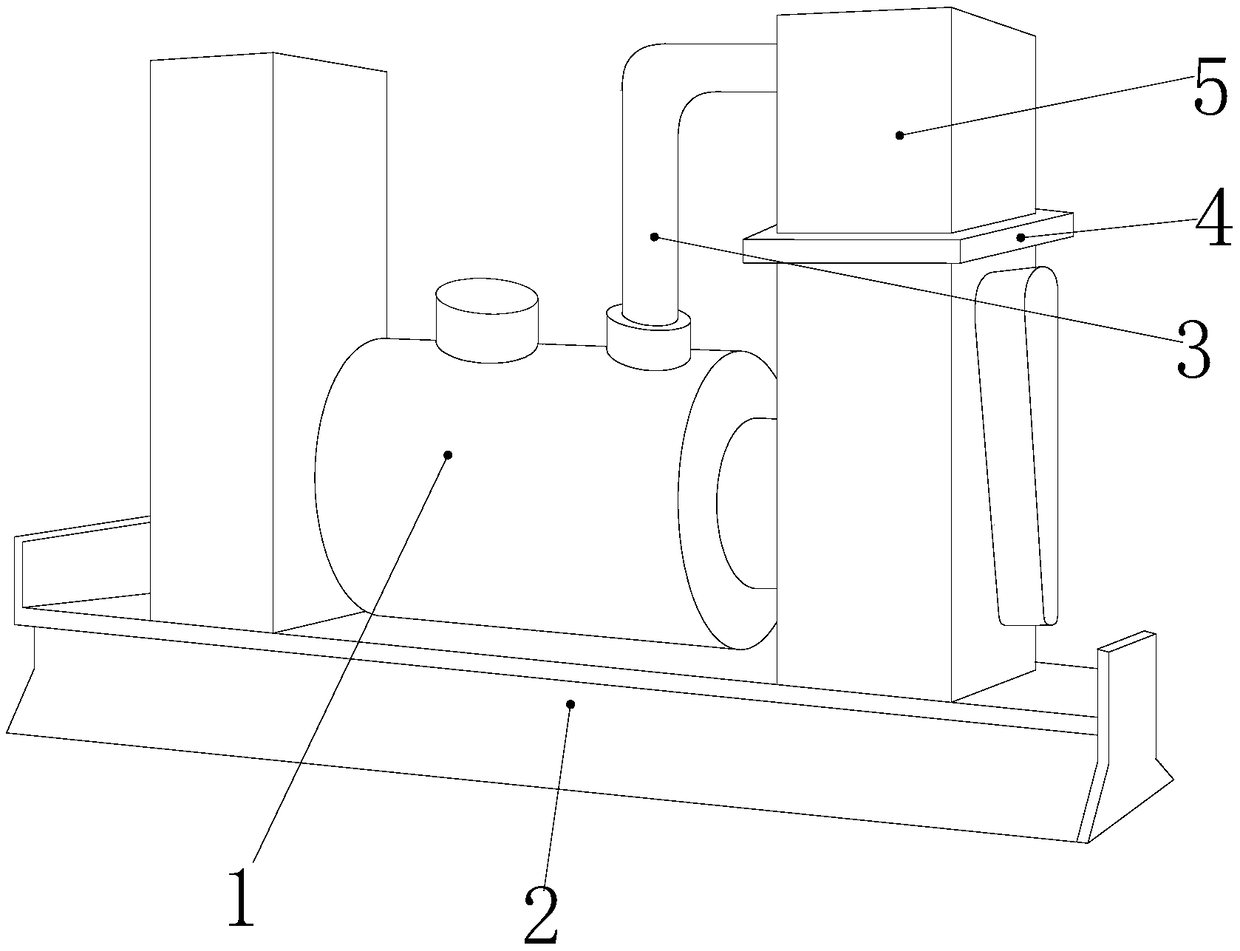

[0026] see Figure 1-Figure 5 , the present invention provides a dust protection device for paint production. Its structure includes a production chamber 1, a base 2, an exhaust pipe 3, a connecting seat 4, and a dust protection device 5. The production chamber 1 is arranged on the base 2 and connected to the base 2. Fixed connection, the connection seat 4 is fixed on one side of the base 2, the dust protection device 5 is fixed on the connection seat 4, one end of the exhaust pipe 3 communicates with the production chamber 1, and the other One end communicates with the dust protection device 5;

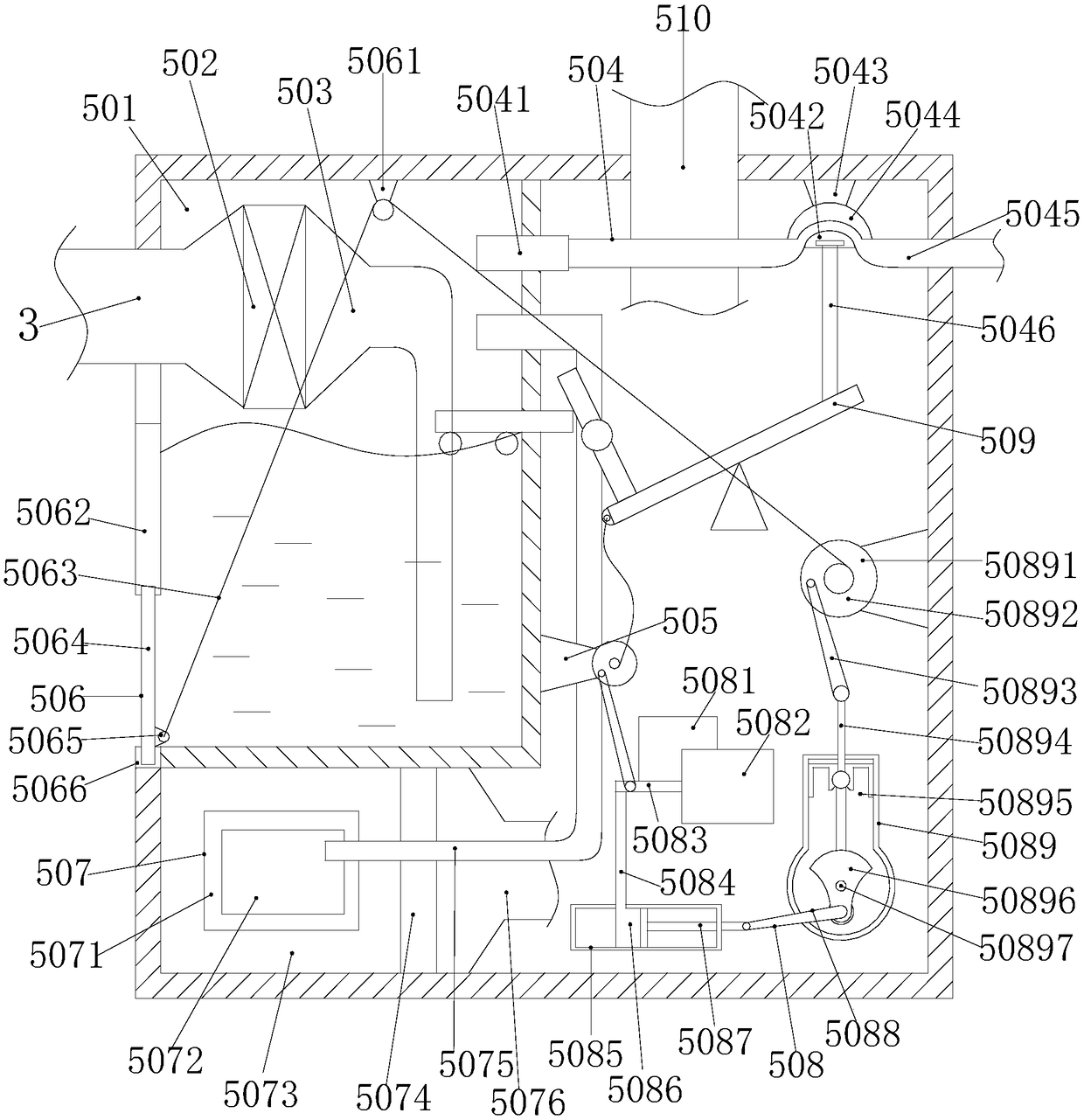

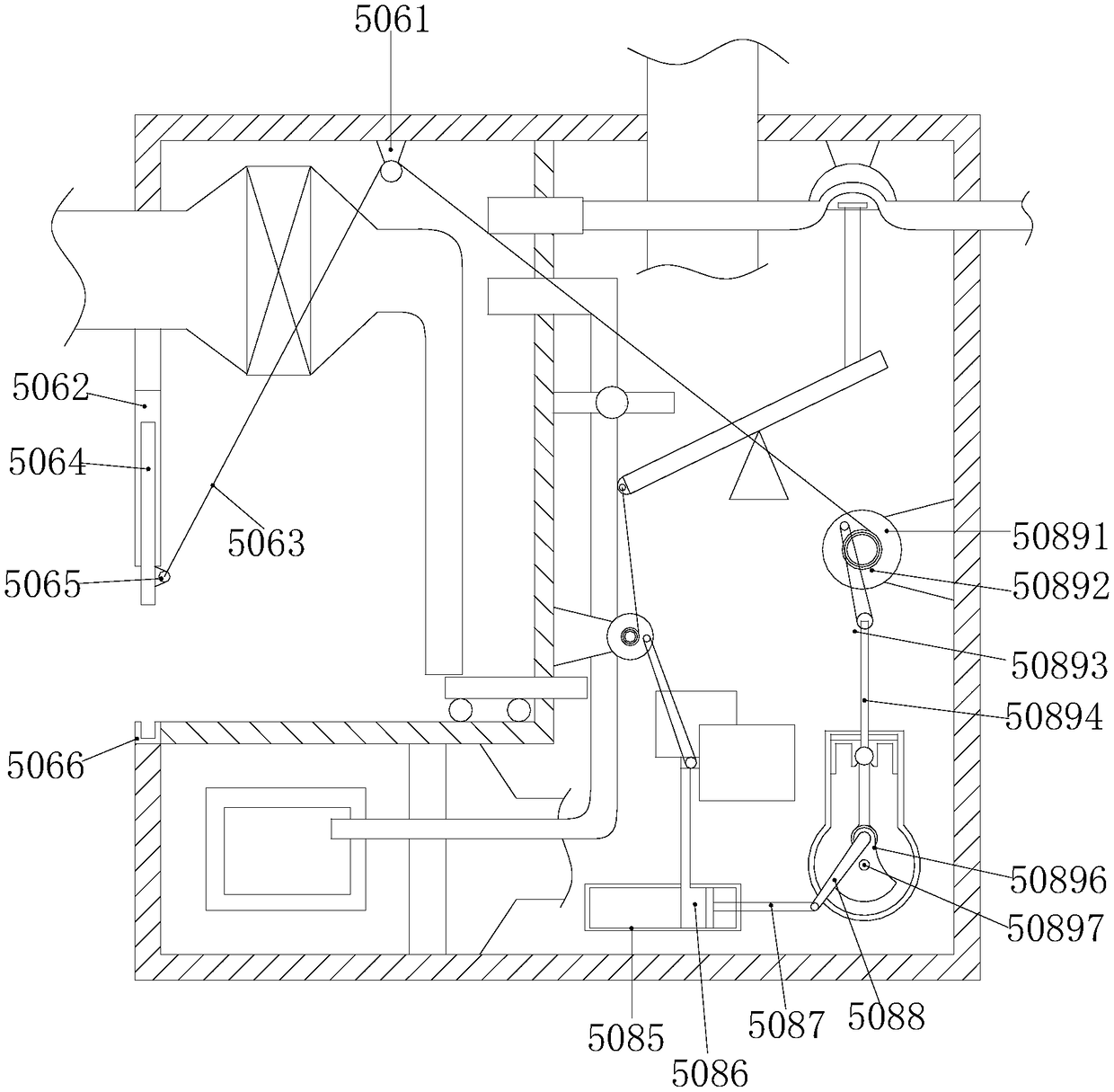

[0027] The dust protection device 5 is driven by a dust precipitation chamber 501, a wind wheel 502, a connecting pipe 503, a water inlet control device 504, an auxiliary control mechanism 505, a drainage mechanism 506, a formaldehyde removal device 507, a driving mechanism 508, and a water inlet control device. Composed of structure 509 and output pipeline 510;

[0028] The connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap