Fine crystal and single crystal dual-function casting furnace, single crystal casting method and fine crystal casting method

A casting furnace, dual-function technology, applied in the direction of single crystal growth, chemical instruments and methods, crystal growth, etc., can solve the problem that the casting furnace cannot have the function of the single crystal furnace and the fine crystal furnace at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

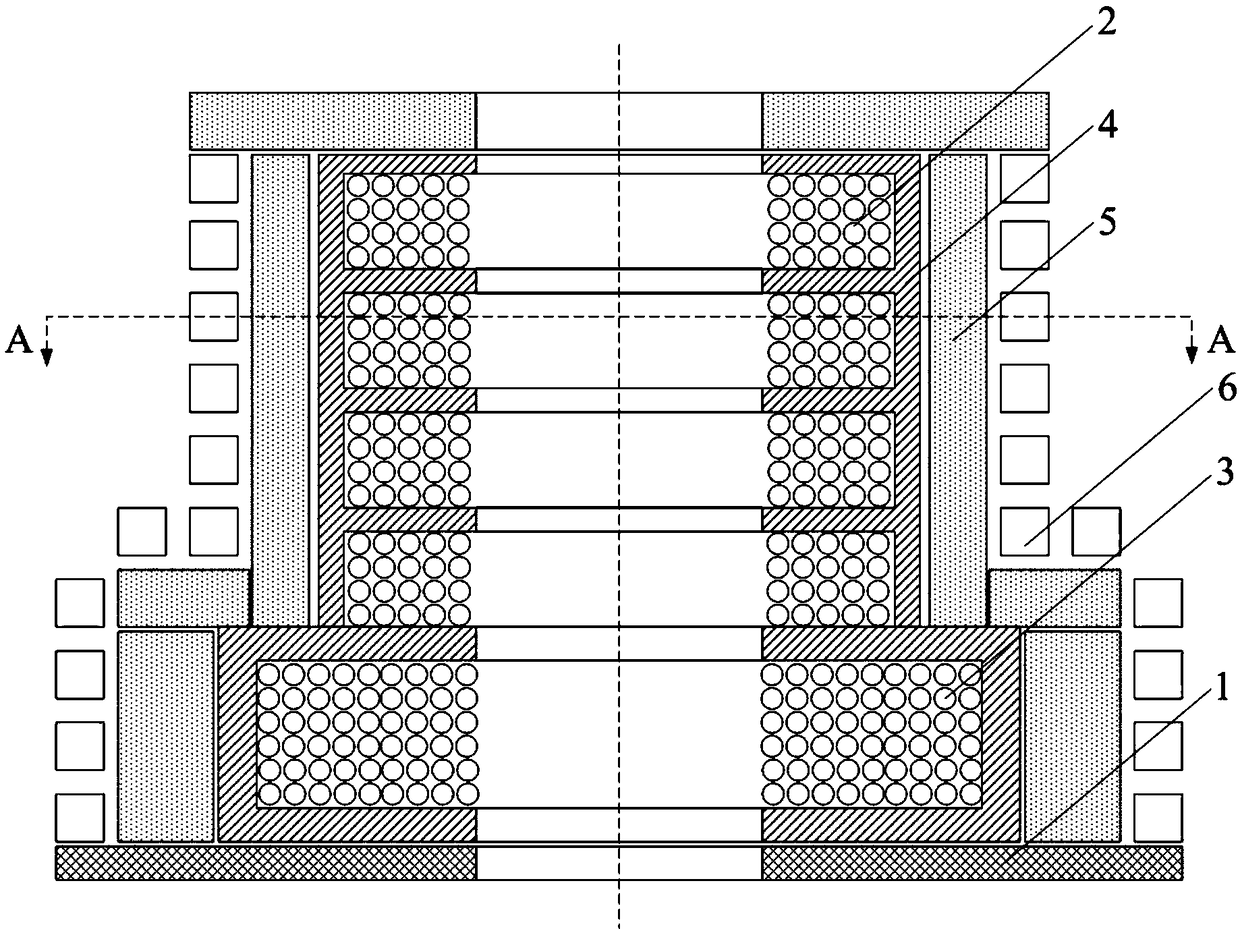

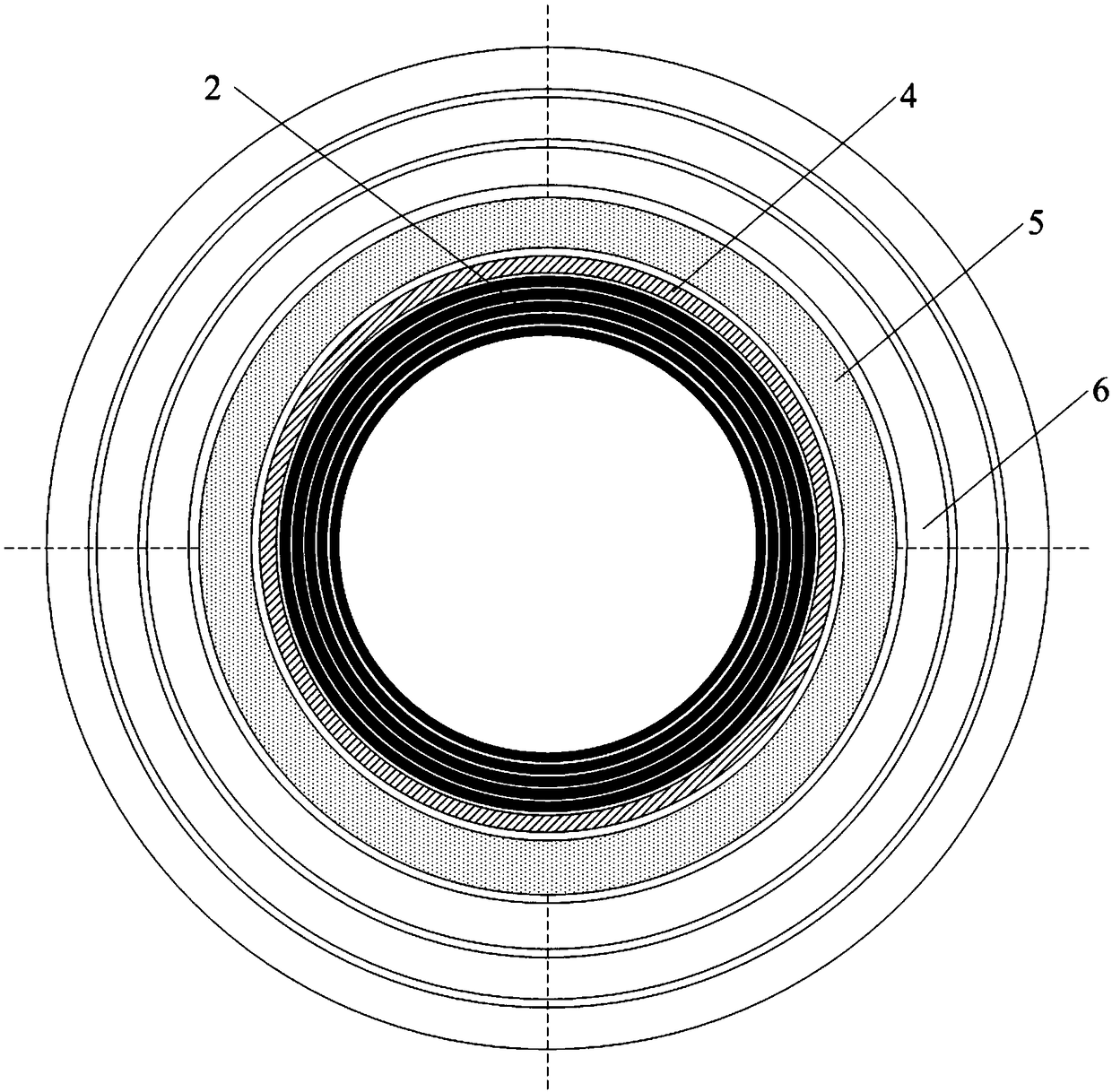

[0040] This embodiment provides a fine-grain, single-crystal double-function casting furnace, including a casting chamber and a drop-down water-cooled crystallizer (not shown) positioned at the bottom of the casting chamber; The ordinary single crystal furnace is the same, but its casting chamber structure and operation mechanism are completely unique, its structure is as follows Figure 1 to Figure 2 As shown, the casting chamber includes a first energized coil 2 and a second energized coil 3, the first energized coil 2 and the second energized coil 3 internal spaces constitute a static magnetic field application zone, and the static magnetic field application zone is also a temperature heating zone; the first The energization coil 2 and the second energization coil 3 are located in the load-bearing groove 4 respectively, and the first energization coil 2 is positioned above the second energization coil 3; Static magnetic field strength, the temperature inside the second ener...

Embodiment 2

[0064] This embodiment provides a fine-grain casting method. The fine-grain single-crystal dual-function casting furnace provided in Embodiment 1 is used. The fine-grain casting method includes the following steps:

[0065] Step 1: Place the mold in the area where the static magnetic field is applied, on the pull-down water-cooled crystallizer, and place the heat insulation layer between the mold and the pull-down water-cooled crystallizer;

[0066] Step 2: Put the master alloy in the melting crucible and add the required deoxidized carbon, and then check whether the temperature measuring device and the peephole are normal and available;

[0067] Step 3: Close the furnace door and vacuumize, the vacuum degree is ≤5Pa, the first energized coil and the second energized coil are energized, and the energized power is 100KW, so that the mold temperature is 1400°C, and the internal static magnetic field strength of the first energized coil reaches 2T. The static magnetic field stren...

Embodiment 3

[0075] This embodiment provides a single crystal casting method, using the fine-grain and single crystal dual-function casting furnace provided in Embodiment 1, the single crystal casting method includes the following steps:

[0076] Step A: Place the single crystal mold in the area where the static magnetic field is applied, on the pull-down water-cooled crystallizer, and clean up the space between the single crystal mold and the upper plane of the crystallizer, and there must be no substances that hinder heat transfer;

[0077] Step B: Place the master alloy in the melting crucible and add the required deoxidized carbon, and then check whether the temperature measuring device and the peephole are normally available;

[0078] Step C: Close the furnace door and vacuumize. The vacuum degree is ≤5Pa, which can ensure that the tungsten alloy coil is not oxidized. The overheating temperature requirement of most single crystal alloys is that the internal static magnetic field stren...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap