Casting valve and coating device with same

A coating device and casting technology, applied in the field of casting valve and coating device, can solve the problems of unstable casting of the casting valve, improve the uniformity of coating, reduce the generation of droplets, and achieve strong continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

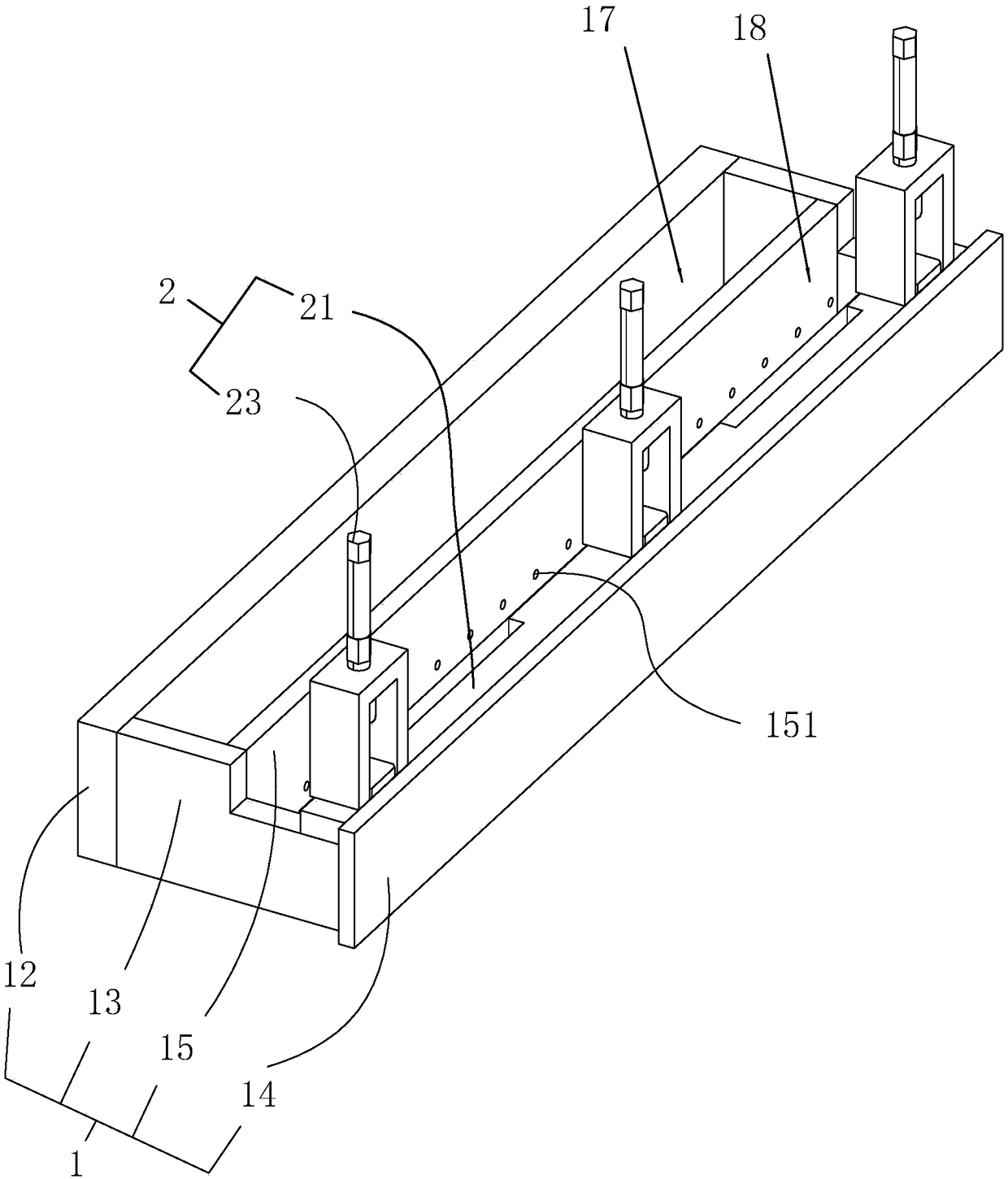

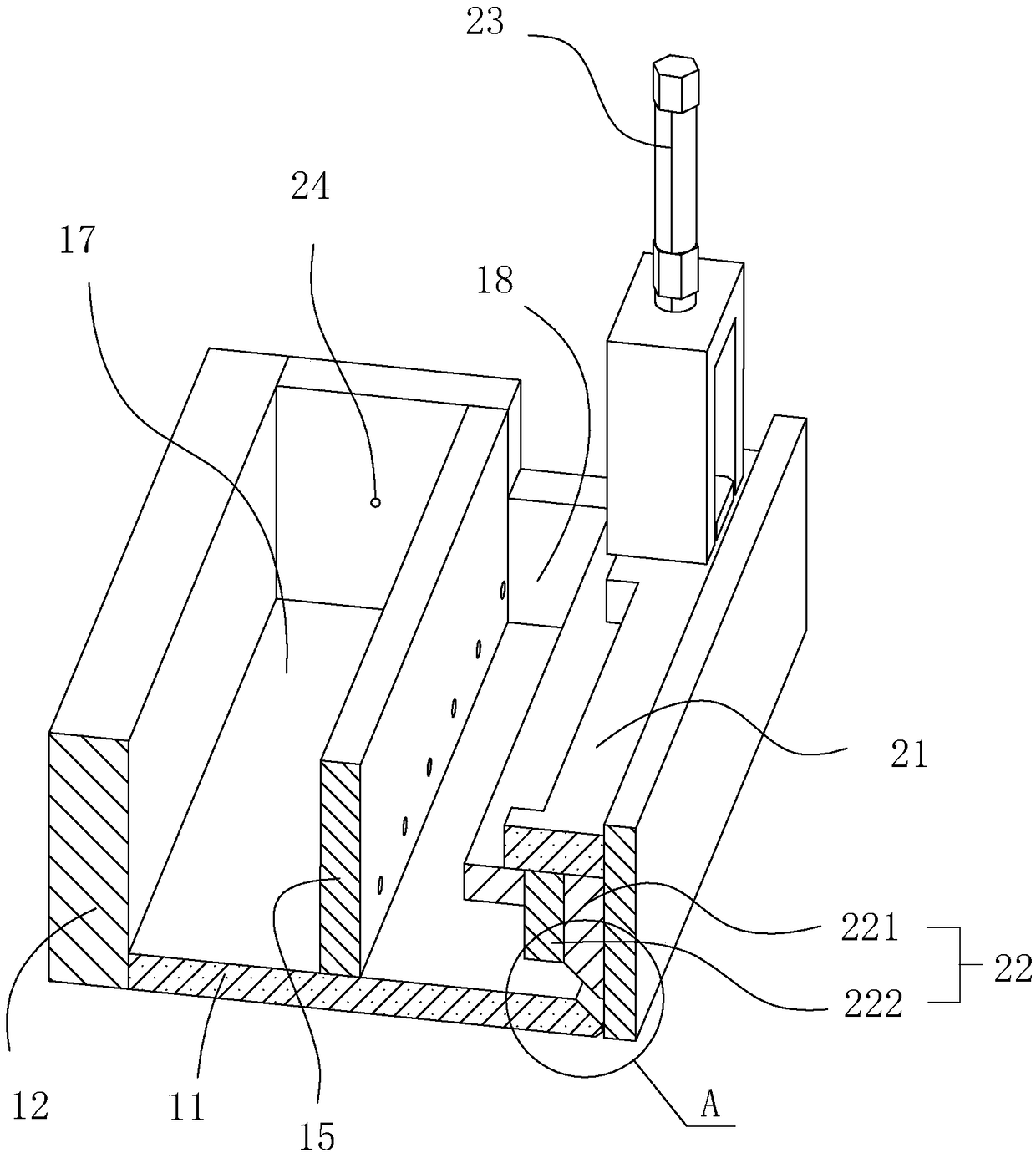

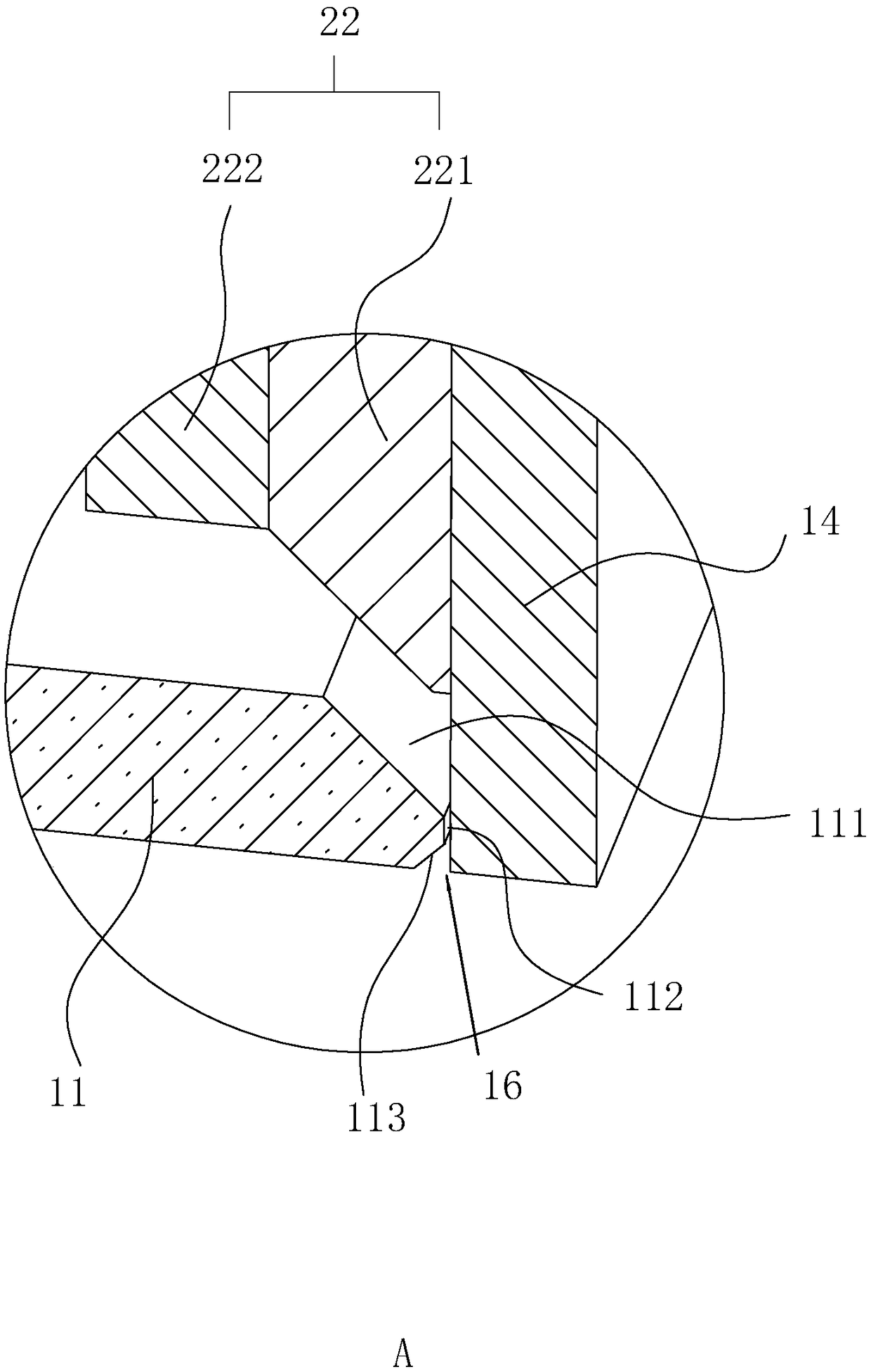

[0040] Embodiment 1: casting valve and the coating device with the casting valve, such as figure 1 and figure 2 As shown, it includes a substrate 1 and a valve 2 , and the valve 2 controls the opening and closing of the liquid outlet 16 of the substrate 1 .

[0041] The base 1 includes a bottom plate 11, a vertical plate 12, a side plate 13 and an end plate 14 that mutually surround a chamber with an upward opening, and also includes a partition that stands in the chamber and divides the chamber into a liquid storage tank 17 and a casting tank 18. The plate 15 and the separator 15 are parallel to the vertical plate 12 and the end plate 14 , and the end plate 14 is located on the side of the casting tank 18 away from the liquid storage tank 17 .

[0042] The upper opening of the liquid storage tank 17 is the liquid inlet, and the lower part of the partition plate 15 is arranged with a plurality of connecting holes 151 connecting the liquid storage tank 17 and the casting tank...

Embodiment 2

[0046] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that the valve 2 also includes a second valve plate 25 that slides along the surface of the partition 15 to cover the connecting hole 151 and is fixed on the base 1 to drive the second valve plate 25 moves the second push cylinder 26 .

[0047] The second valve plate 25 and the first valve plate 22 both can finish opening and closing action simultaneously, also can finish opening and closing action respectively; The amount of solution can always be kept at a constant liquid level at the bottom, and can also be kept at a constant flow rate; when it is respectively opened and closed, quantitative coating can be completed, that is, when the liquid outlet 16 is closed, the solution begins to accumulate in the casting tank 18, Then, the contact holes 151 are closed during coating.

Embodiment 3

[0048] Embodiment 3: as Figure 5 As shown, the difference from Embodiment 1 or 2 is that the end plate 14 and the bottom plate 11 are abutted and closed, the end plate 14 is lower than the other side walls of other casting grooves 18, and the ends of the end plate 14 are respectively provided with Inclined inner guide surface and outer guide surface; when closed, the end of the first valve plate 22 abuts against the inner guide surface and the outer guide surface at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com