Electric furnace flip type counter-rotating quenching structure

A flip-type, electric furnace technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of inconvenient material feeding and automatic unloading, and achieve the effect of convenient unloading, convenient connection, and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

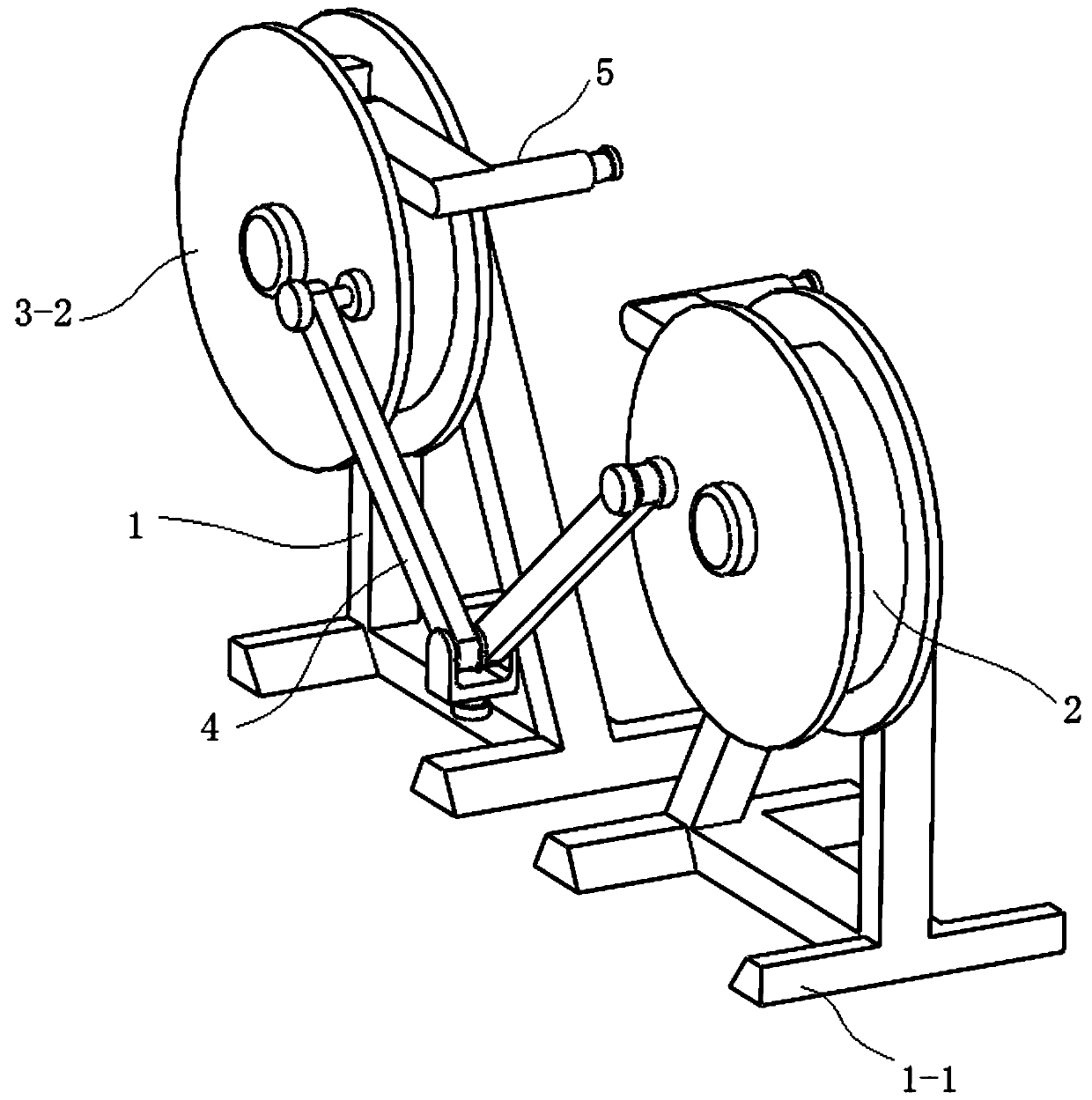

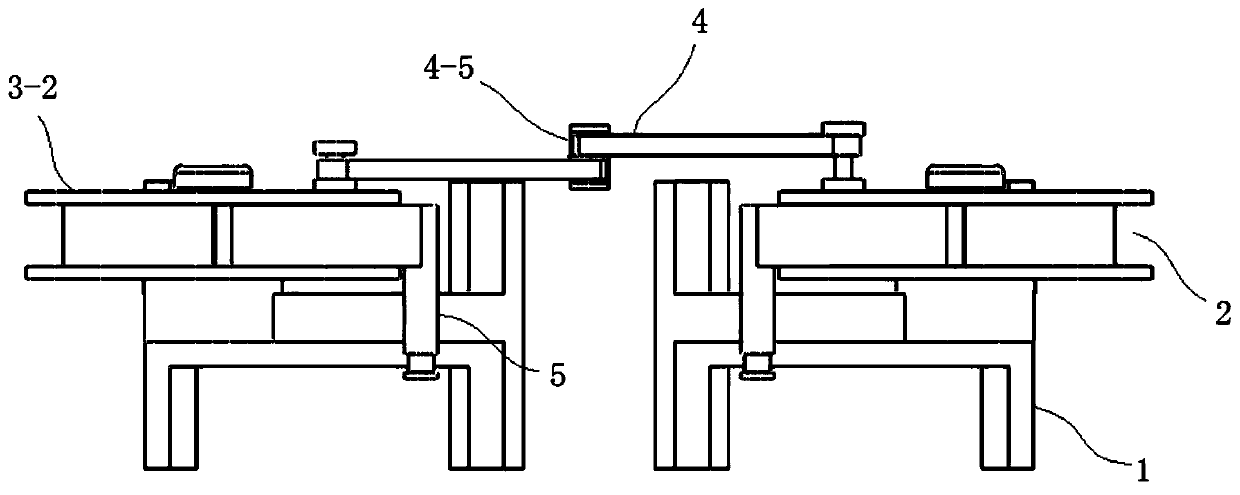

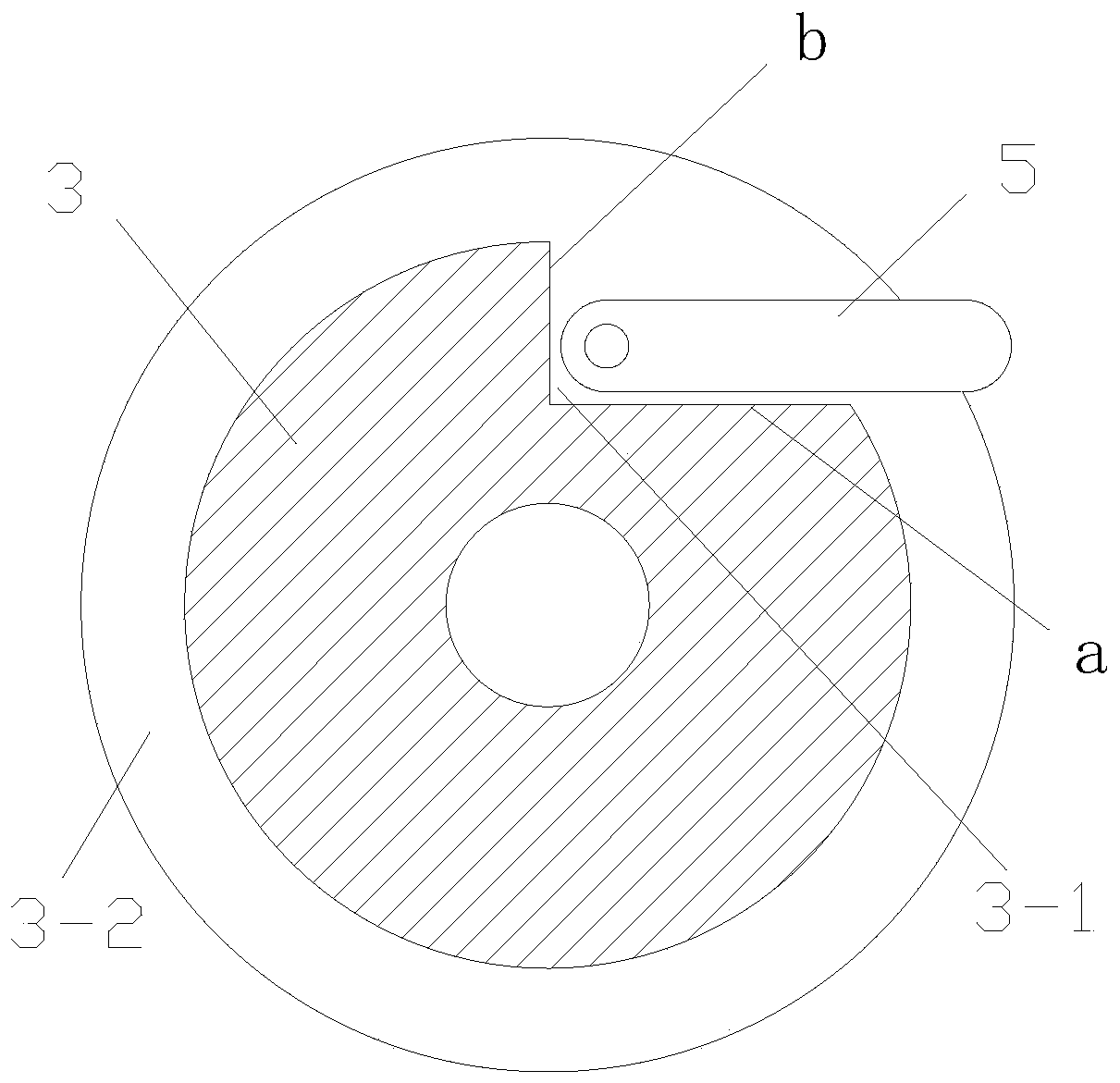

[0027] Such as Figure 1-2 Shown is an electric furnace flip-type counter-rotating quenching structure, including a bracket 1, and also includes a set of counter-rotating structures 2 and a driving motor arranged on the same side of the bracket 1. The counter-rotating structure 2 is composed of two counter-rotating wheels 3 and counter-rotating The connecting rod mechanism 4 between the rotating wheels and the turning material lifting rod 5 arranged on the counter rotating wheels 3 constitute, the driving motor is connected with the connecting rod mechanism 4, the counter rotating wheels 3 are vertically spaced apart and the surface of the counter rotating wheels is connected with the connecting rod. The rod mechanism 4 is connected, and the overturning lifting rod 5 is arranged around the counter-rotating wheel 3 and is connected in rotation with the counter-rotating wheel 3. The driving motor is connected with the middle part of the link mechanism 4 and drives the counter-rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com