Crocheting machine

A crochet machine and encoder technology, applied in the field of crochet machines, can solve the problem of high cost, achieve the effect of convenient and adjustable speed, and ensure smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

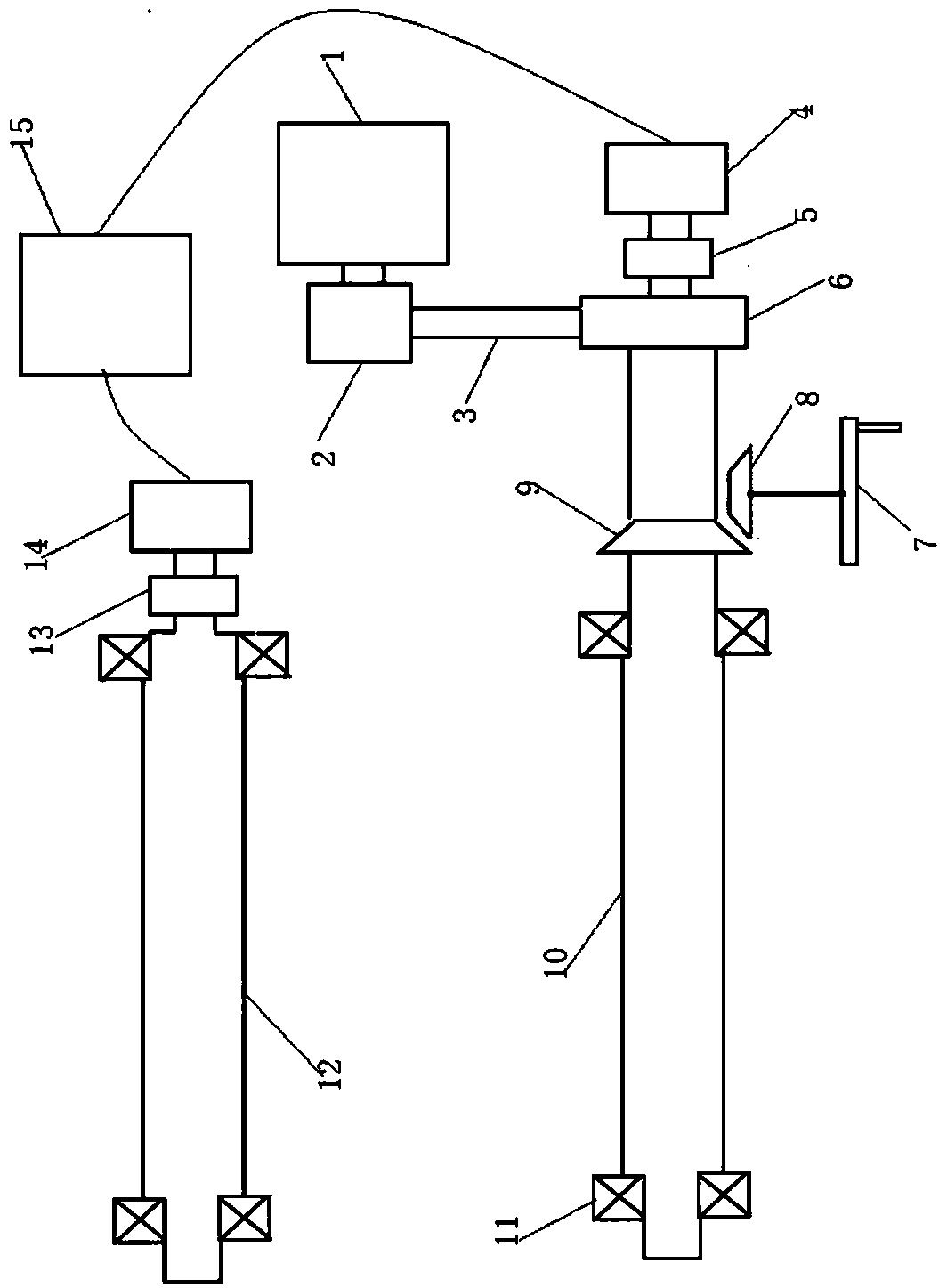

[0011] a crochet machine, see figure 1 : it includes a main shaft 10 and a weft yarn shaft 12, the main shaft 10 is connected to the output end of the main motor 1, one end of the main shaft 10 is connected to the encoder 4 through the first shaft coupling 5, and the signal output end of the encoder 4 is externally connected to the driver 15, The driver 15 is built with an output speed coefficient setting, the signal output end of the driver 15 is connected to the servo motor 14, the output end of the servo motor 14 is connected to the input end of the weft yarn shaft 12, the first bevel gear 9 is set on the main shaft 10, and the external The second bevel gear 8 meshes with the first bevel gear 9 , and a rotating handle 7 is arranged on the central axis of the second bevel gear 8 .

[0012] The output end of the main motor 1 is equipped with a main motor pulley 2, and the outer ring part of the input section of the main shaft 10 is equipped with a corresponding main shaft pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com