High temperature resistant inserted type centrifugal fan

A centrifugal fan and plug-in technology, used in electromechanical devices, mechanical equipment, non-variable-capacity pumps, etc., can solve the problem that the cooling capacity of the fan does not meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

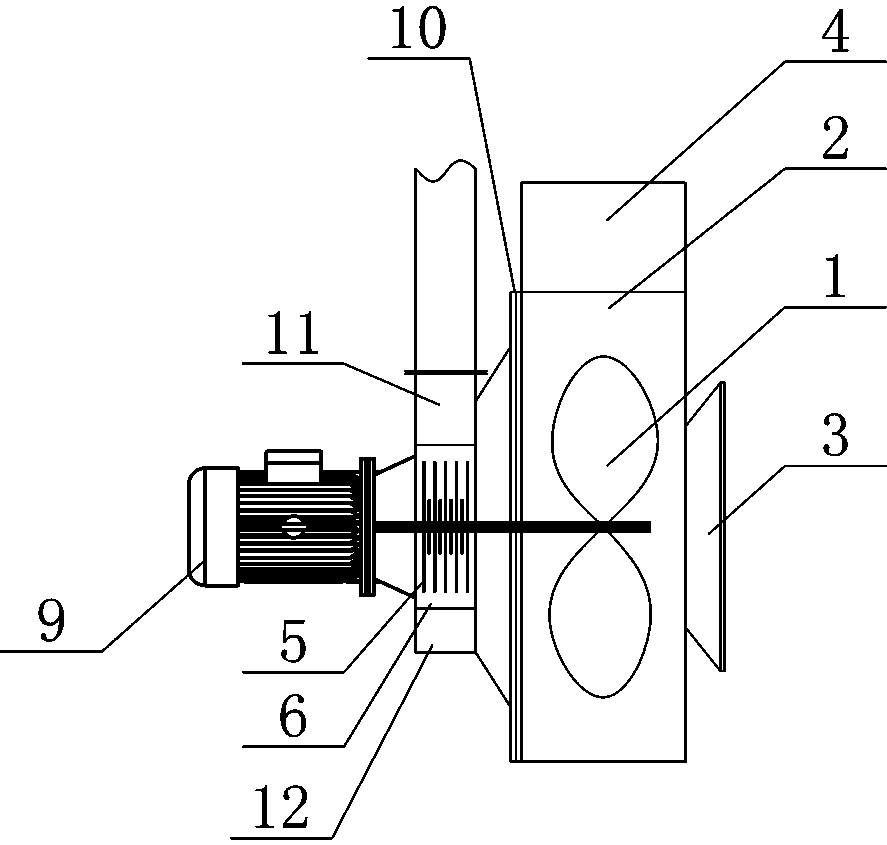

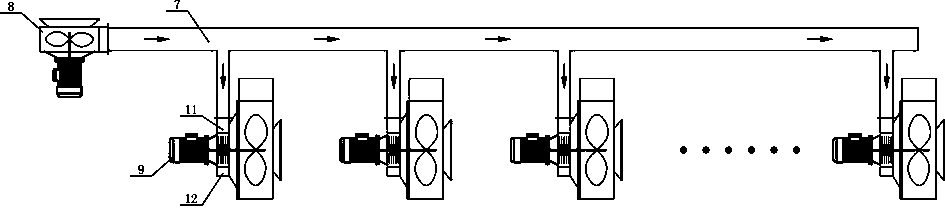

[0017] Depend on Figure 1-2 As shown in the figure, it includes a long-axis motor 9 with a long drive shaft, a main fan with a main fan impeller 1, a main fan volute 2, a fixed disk 10, a cooler, an air supply duct 7, and an air supply fan. 8. The main fan is arranged at the front end of the long drive shaft, and a cooler is arranged on the long drive shaft between the long shaft motor 9 and the main fan, and the cooler is composed of a cooling disc group 5 and a structural cavity 6; The disc group 5 is made of multiple metal plates with thermal conductivity and is crimped on the long drive shaft. It is a comb-shaped concentric heat sink composed of concentric discs with different diameters. The structural cavity 6 is provided with a cooling air inlet. 11 and the cylindrical metal member of the cooling air outlet 12; the air supply duct 7 is composed of a metal pipe connected to the air supply fan 8 at one end and the other end is connected to the cooling air inlet 11; the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com