Accurate measurement method for escaping ammonia after SCR device in thermal power plant

A thermal power plant, accurate measurement technology, applied to the analysis of materials, instruments, etc., can solve the problems of large cross-sectional area of the downstream flue, uneven velocity distribution, complex smoke flow field, etc., and achieve good reproducibility and accurate measurement results The effect of being accurate and avoiding the deviation of flue gas composition measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

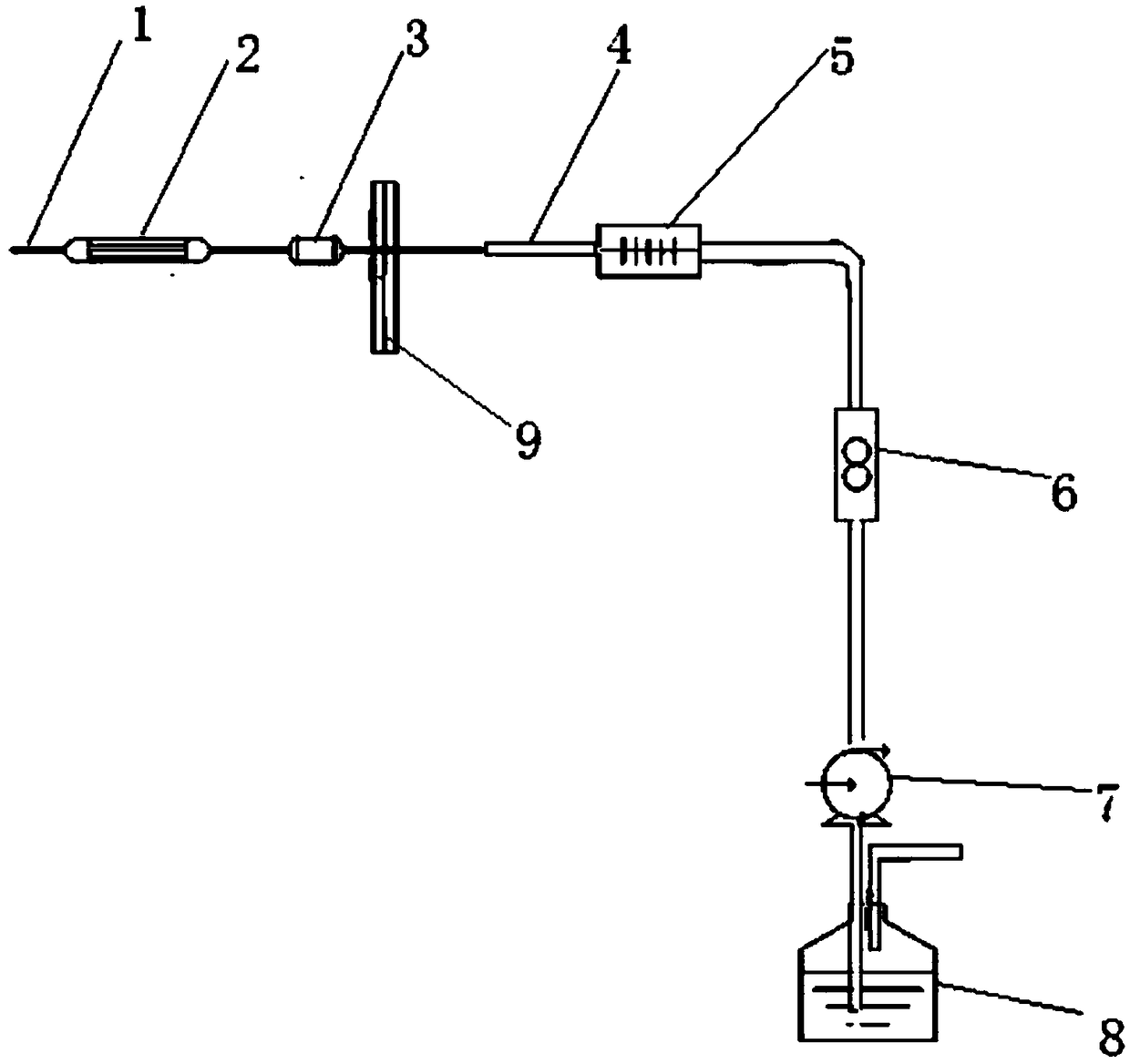

[0022] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

[0023] Such as figure 1 Shown, a kind of thermal power plant SCR device back escape ammonia accurate measurement method, comprises the following steps:

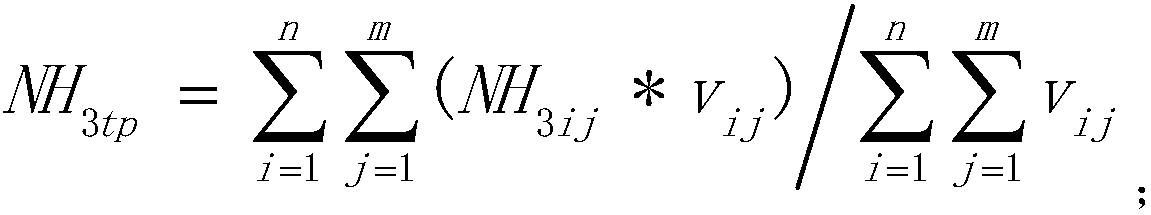

[0024] (1) Choose a rectangular flue section as the measurement plane between the outlet of the SCR device and the inlet of the air preheater, and divide the section of the flue into m×n measuring points;

[0025] (2) Put the sampling gun 1 into a certain measuring point and fix it on the furnace wall 9, turn on the air pump 7, and the flue gas slowly enters the sampling g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com