Method for discriminating depth of nonconductor defect based on multi-pair electrode capacitance imaging detection technology

A technology of capacitive imaging and multiple pairs of electrodes, which is used in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as multi-time, only the upper or lower information of non-conductive materials, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

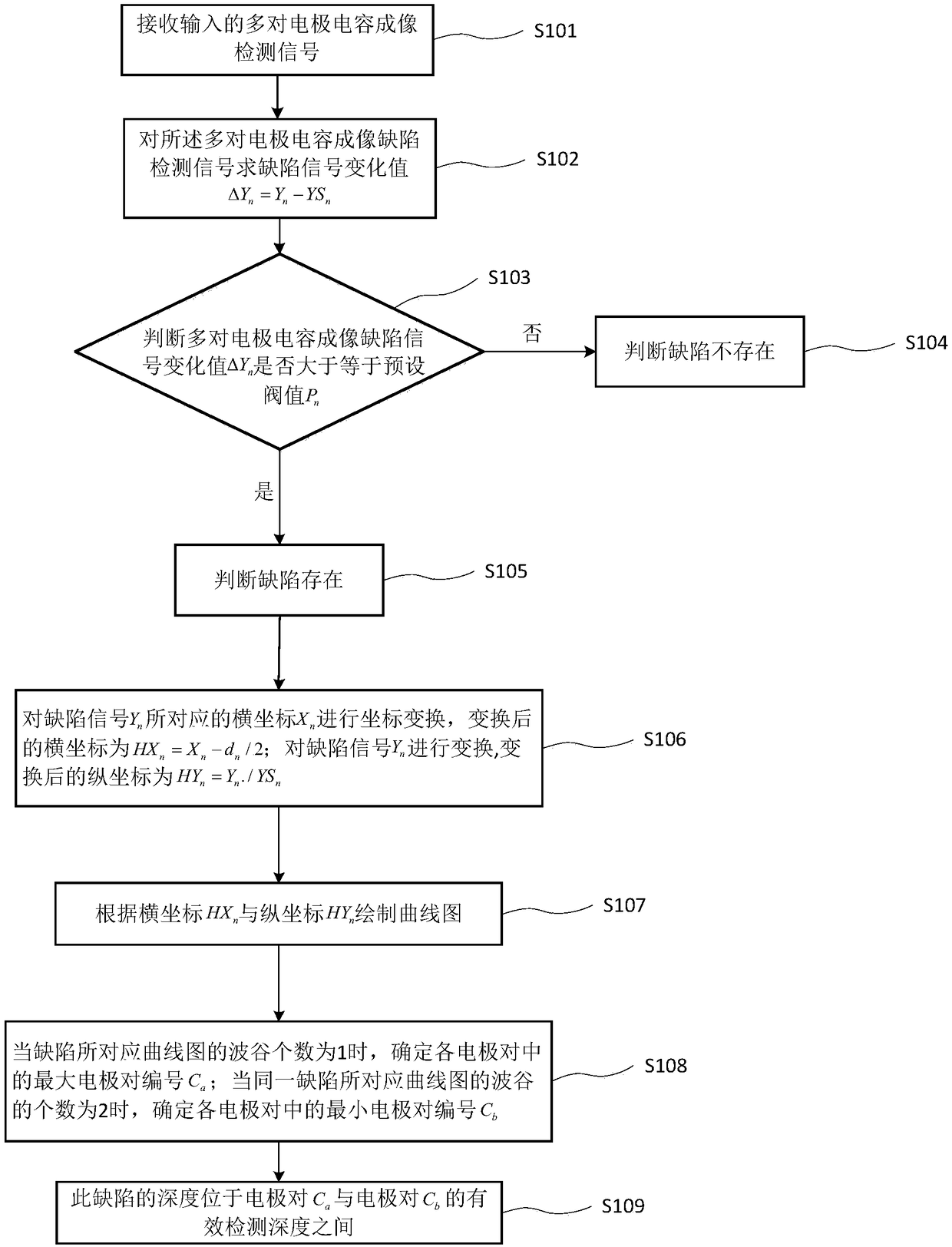

[0018] figure 1 Schematic diagram of a method for judging the depth of non-conductor defects based on multi-pair electrode capacitive imaging detection technology provided for the embodiment of the present invention Figure 1 , as shown, including:

[0019] S101. Receive input capacitance imaging detection signals of multiple pairs of electrodes, wherein the detection signals of capacitance imaging of multiple pairs of electrodes include each electrode pair (C 1 、C 2 ...C n ) to the detection signal (Y 1 , Y 2 、…Y n ) and each electrode pair (C 1 、C 2 ...C n ) to the detection signal of a non-defective test piece of the same material (YS 1 , YS 2 、…YS n ).

[0020] Specifically, the signal and mathematical processing software receives the input detection signal, wherein the input detection signal is the detection signal input by multiple pairs of electrode capacitive imaging detection probes at the same lift-off height L, and the detection signal includes the detec...

Embodiment 2

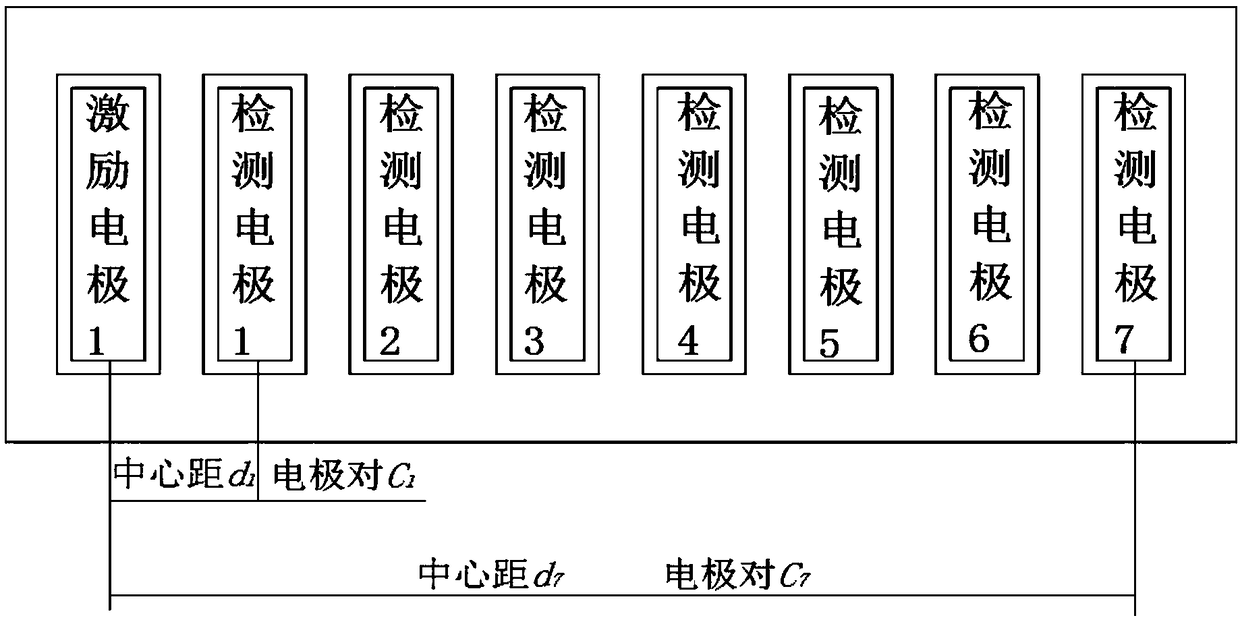

[0031] Based on a method for discriminating the depth of non-conductor defects based on multi-pair electrode capacitive imaging detection technology provided in Embodiment 1, this embodiment provides an experiment in which the number of multi-electrode plates is a specific value (for example, n=7 is used, and the following will not be redundant). Implement the method to verify the effectiveness of the method.

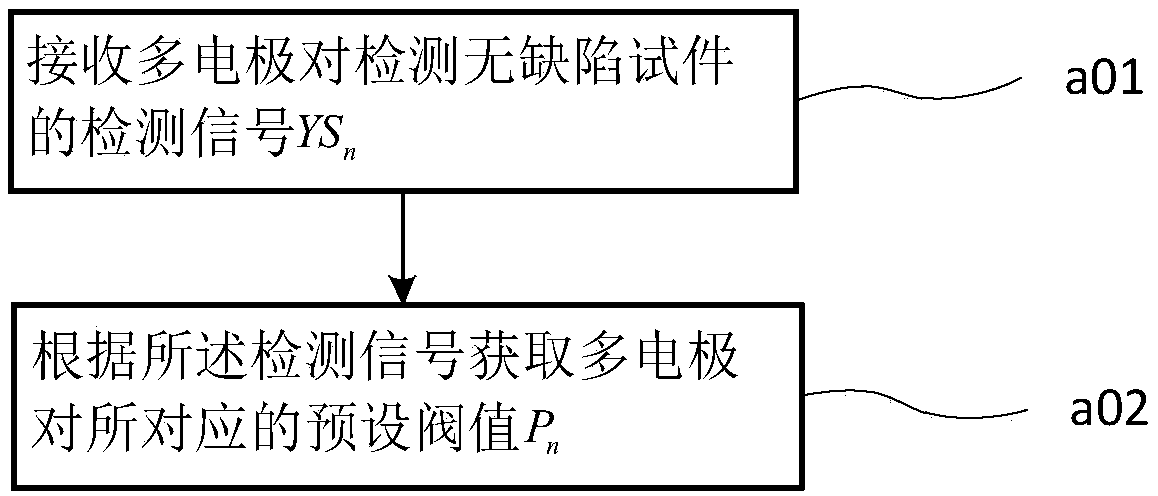

[0032] The receiving detection probe (such as image 3 Each electrode pair (C 1 、C 2 、C 3 、C 4 、C 5 、C 6 、C 7 ) for test pieces with defects (such as Figure 4 shown) detection signal (Y 1 , Y 2 , Y 3 , Y 4 , Y 5 , Y 6 , Y 7 ) and each electrode pair (C 1 、C 2 、C 3 、C 4 、C 5 、C 6 、C 7 ) to the detection signal of a non-defective test piece of the same material (YS 1 , YS 2 , YS 3 , YS 4 , YS 5 , YS 6 , YS 7 ); According to the multi-electrode pair (C 1 、C 2 、C 3 、C 4 、C 5 、C 6 、C 7 ) to detect the detection signal of the non-defective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com