Rice screening and bagging device

A bagging device and rice technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problem of low purity of screening, and achieve the effect of simple structure and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

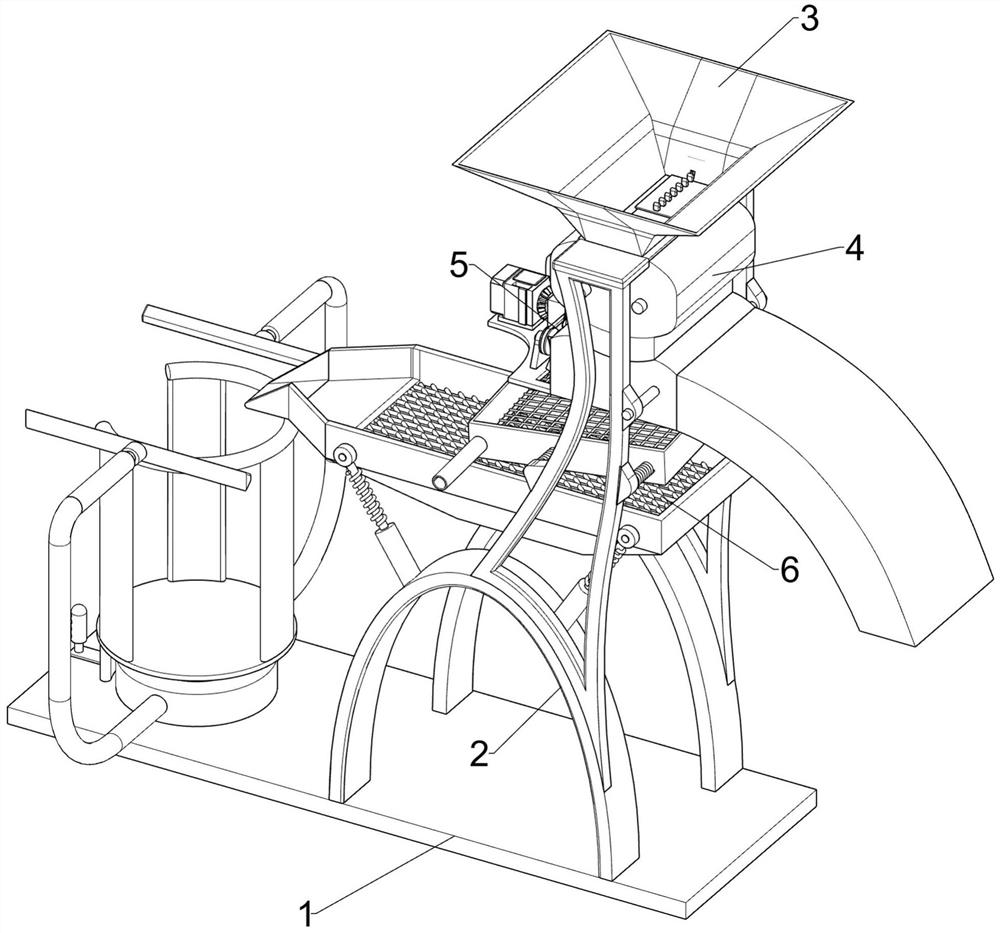

[0025] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, a rice screening and bagging device includes a base 1, a mounting frame 2, a lower hopper 3, a skin breaking mechanism 4, a winnowing mechanism 5 and a screening mechanism 6, and the top of the base 1 is symmetrically provided with a mounting frame 2, two A lower hopper 3 is arranged between the mounting frame 2 tops, and a skin breaking mechanism 4 is arranged on the tops of the two mounting frames 2. The skin breaking mechanism 4 cooperates with the lower hopper 3, and the skin breaking mechanism 4 bottom is provided with a winnowing mechanism 5, and the winnowing mechanism 5 cooperates with breaking skin mechanism 4, is provided with screening mechanism 6 between two installation frames 2 bottoms, and screening mechanism 6 is coordinated with breaking skin mechanism 4 transmissions.

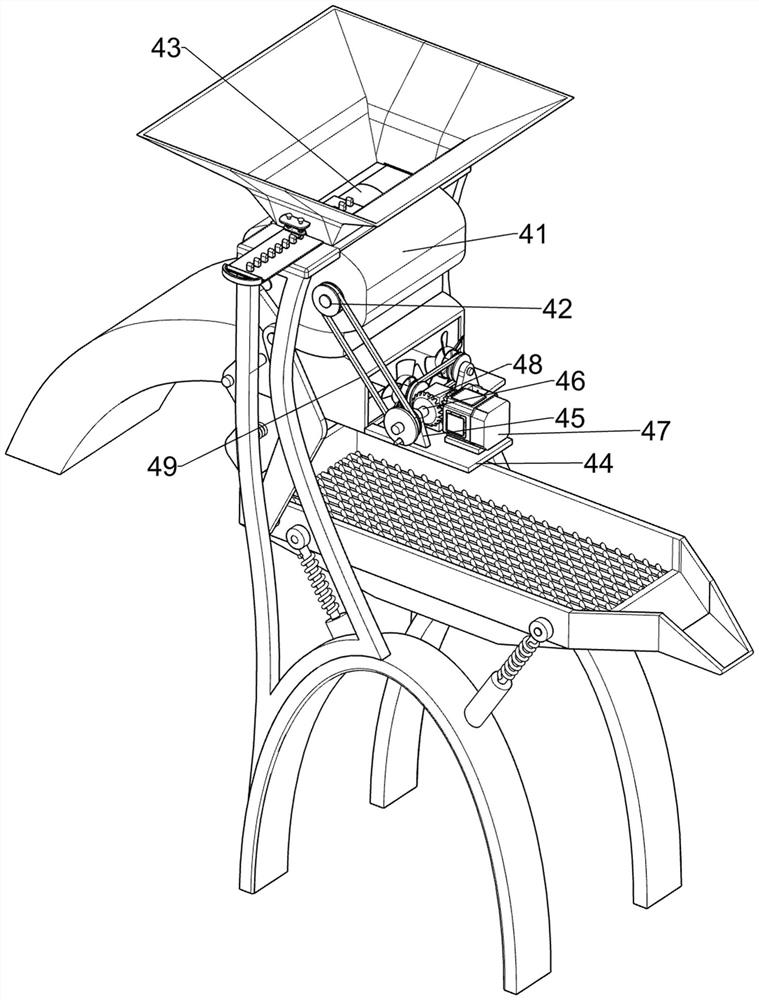

[0026] The broken skin mechanism 4 includes a processing cylinder 41, a rotating shaft 42, a broken skin roller 43, a ...

Embodiment 2

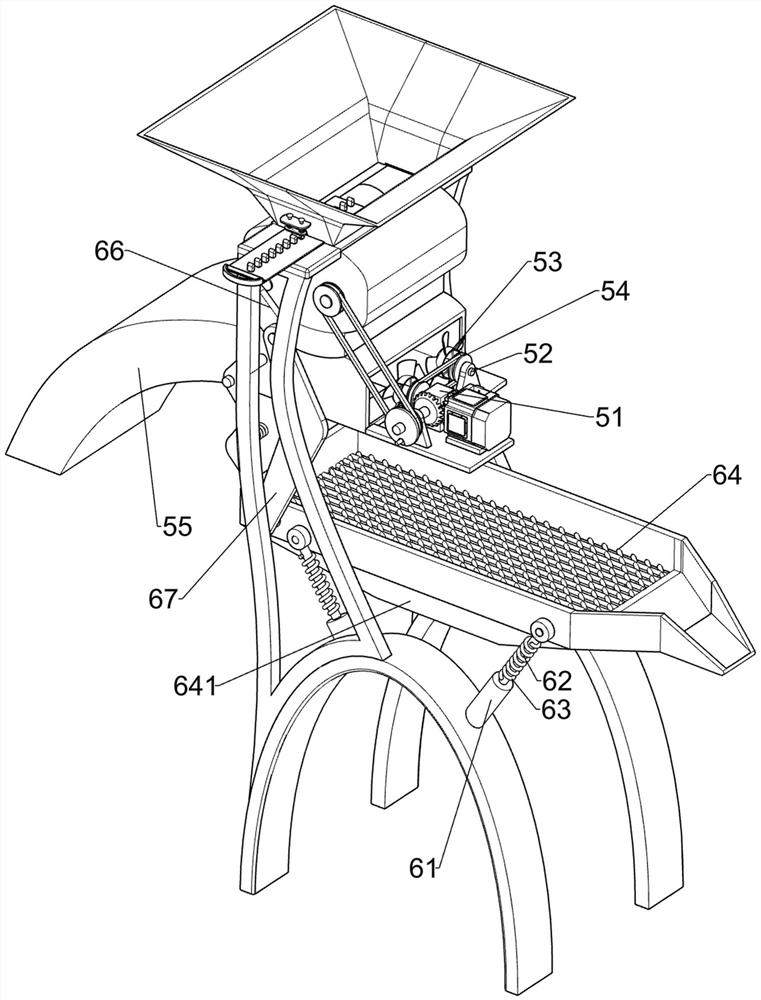

[0031] Such as Figure 4 and Figure 5As shown, on the basis of Embodiment 1, it also includes a second elastic member 7, a screening frame 8, a top block 9, a disc 10 and a cam 11, and the opposite ends of the middle parts of the two installation frames 2 are provided with a second elastic member 7. The second elastic member 7 is a tension spring, a screening frame 8 is arranged between the second elastic members 7, a top block 9 is arranged on the side wall of the screening frame 8, a disc 10 is arranged at the end of the first rotating shaft 46, A cam 11 is arranged on the left side of the rear side wall of the disc 10, and the cam 11 cooperates with the top block 9.

[0032] The first rotating shaft 46 drives the disc 10 and the cam 11 to perform circular motion. When the cam 11 squeezes the top block 9, the top block 9 drives the screening frame 8 to vibrate, and the second elastic member 7 deforms. When the cam 11 does not squeeze the top block 9 , the second elastic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com