Frequency selective surface with high angular stability

A frequency selective surface, high-angle technology, applied in the field of electromagnetic field and microwave, can solve the problem of low angular stability, and achieve the effect of reducing offset, reducing unit size, and improving angular stability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

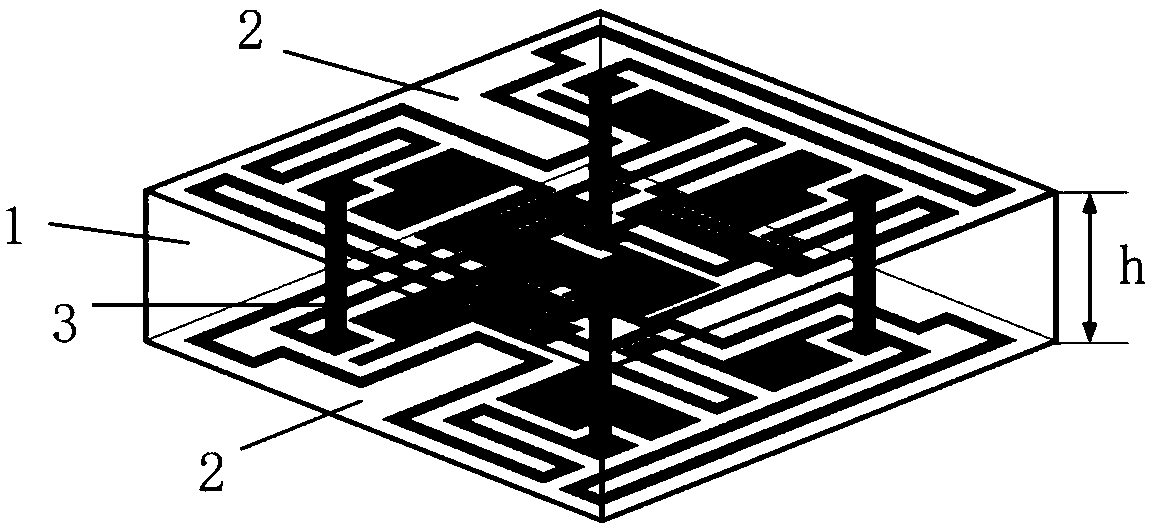

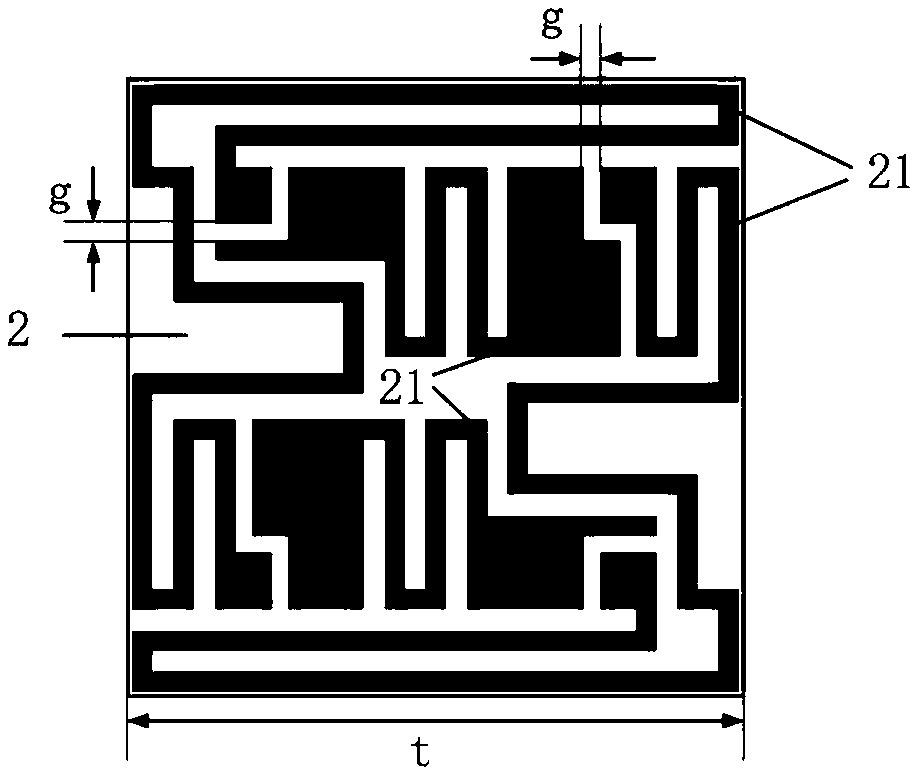

[0029] refer to figure 1 , a frequency selective surface unit with high angle stability, the frequency selective surface unit includes a dielectric substrate 1 , metal patches 2 printed on the upper and lower surfaces of the dielectric substrate 1 , and metallized via holes 3 .

[0030] The dielectric substrate 1 adopts a square plate with a relative permittivity of 2.2, its side length is t=6.7mm, and its thickness is h=1.6mm.

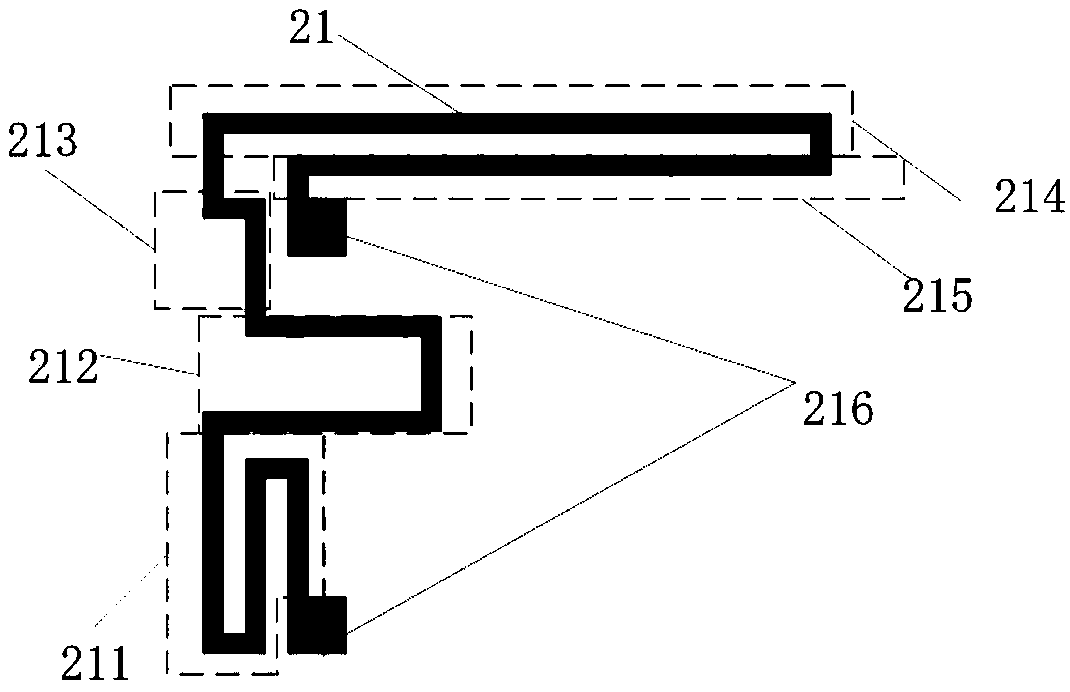

[0031] The pair of metal rings on the lower surface of the dielectric substrate 1 is located at a position where the projection of the pair of metal rings on the upper surface is rotated by 90 degrees on the lower surface, and the opening ends of the pair of split metal rings on the upper surface are aligned with the pair of metal rings on the lower surface. The corresponding positions of the open ends of the split metal ring pair are connected through the metallized via hole 3, and the connection line between the corresponding ports of the split meta...

Embodiment 2

[0045] The structure of this embodiment is the same as that of Embodiment 1, and only the following parameters have been adjusted:

[0046] The dielectric substrate 1 adopts a relative permittivity of 4.4, a length of t=8mm, a thickness of h=3mm, a length of the metal patch a of 7.9mm, a line width of w=0.1mm, g=0.1mm, r=0.25mm.

Embodiment 3

[0048] The structure of this embodiment is the same as that of Embodiment 1, and only the following parameters have been adjusted:

[0049] The dielectric substrate 1 adopts a relative dielectric constant of 4.4, a length of t=6mm, a thickness of h=3mm, a length of the metal patch a of 5.9mm, a line width of w=0.3mm, g=0.3mm, r=0.1mm.

[0050] Below by simulation experiment, the technical effect of the present invention is described further:

[0051] 1. Simulation conditions and simulation content:

[0052] The simulation utilizes the commercial software HFSS_15.0.

[0053] Simulation 1, the transmission coefficient curve of the TE wave in the embodiment 1 of the present invention is simulated from the incidence angle 0 ° ~ 87 °, and the results are as follows Figure 7 shown.

[0054] Simulation 2, the TM wave in the embodiment of the present invention 1 is simulated from the transmission coefficient curve of the incident angle 0 ° ~ 87 °, the result is as follows Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com