Frequency converter cabinet body with adjustable heat dispersion

A heat dissipation and cabinet technology, applied in the modification of power electronics, AC motor control, output power conversion device, etc., can solve the problem of unsatisfactory heat dissipation function, achieve good heat dissipation performance and protect facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

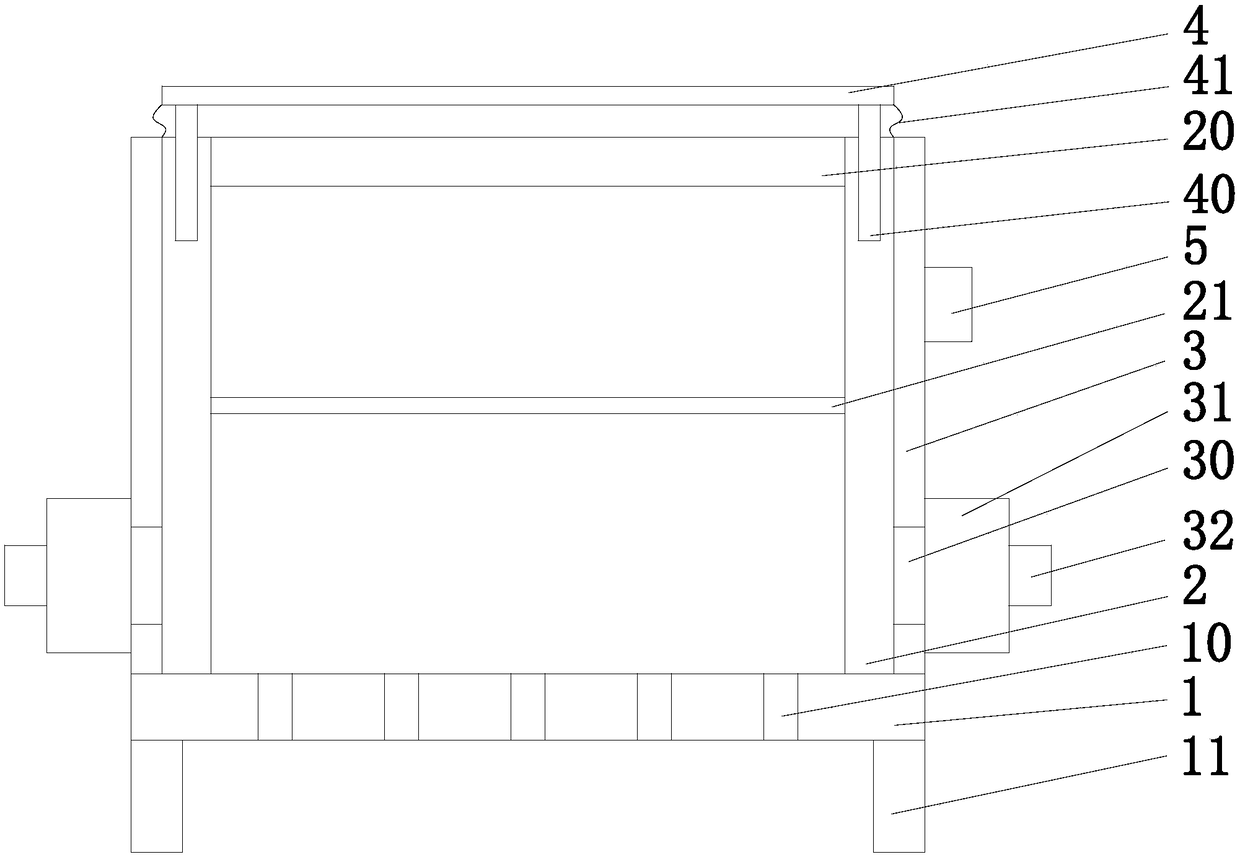

[0015] Refer to figure 1 , The present invention is a variable frequency cabinet cabinet with adjustable heat dissipation, comprising a bottom plate 1, a column 2, a connecting rod 20, an outer cover 3, a top plate 4, a fan 31, a lifting column 40, a gauze ring 41, and a control device 5. The bottom plate 1 is a rectangle, each of the four corners of the upper end surface of the bottom plate 1 is fixed with a column 2 and the top ends of the columns 2 are connected by connecting rods 20. There are four connecting rods 20, four connecting rods 20 and four pillars 2 The top ends together constitute a rectangular frame. The outer cover 3 is a rectangular parallelepiped cover with both upper and lower ends open. The outer cover 3 surrounds the four uprights 2, and the outer cover 3 is fixed to the upright 2 and the connecting rod 20 by a number of screws. Fans 31 are fixed on the outer walls of the left and right sides of the outer cover 3, and air inlet windows 30 matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com