Anti-shaft-wrapping structure and anti-shaft-wrapping method of concrete mixer

A concrete mixer and mixing shaft technology, which is applied to mixer accessories, mixers, cement mixing devices, etc., can solve problems such as shaft wrapping and lack of special research, reducing the number of cleanings, saving maintenance costs for mechanical parts, and mixing efficiency. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

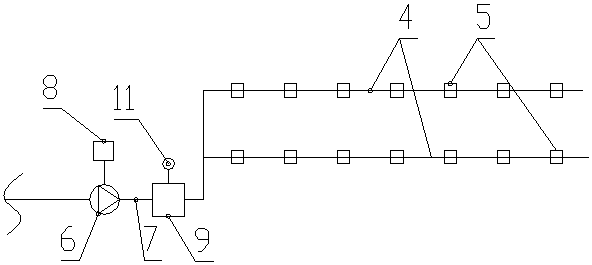

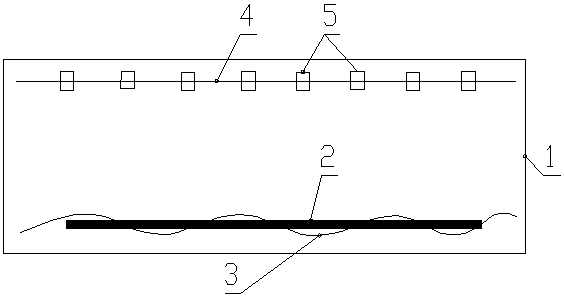

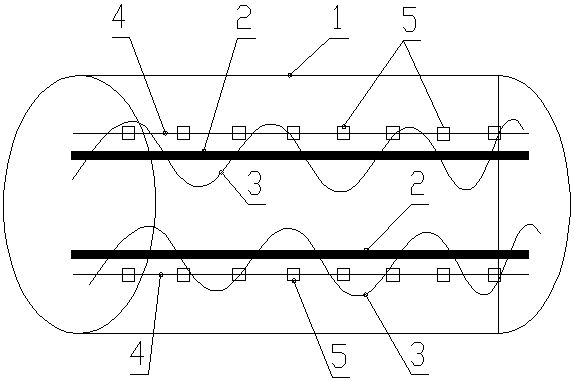

[0040] Such as Figure 1 to Figure 6 As shown, the anti-wrapping shaft structure of the concrete mixer of the present invention includes a mixing tank 1 of the mixer, and two mixing shafts 2 are arranged side by side on the same horizontal plane in the mixing tank 1, and each mixing shaft 2 is provided with a spiral mixing blade 3;

[0041] A flushing water pipe 4 is arranged on the top of each stirring shaft 2, and a plurality of nozzles 5 are installed at intervals on each flushing water pipe 4. The water spraying area forms a cone-shaped area from top to bottom, and the angle α between the two busbars on the same vertical section of the cone-shaped area is 65±2 degrees; this angle can ensure that the agitator shaft that cannot be washed in the past can be washed 2 dead angle, flush the stirring shaft 2 without dead angle.

[0042] A flushing water pump 6 is arranged outside the mixing tank 1, and the water inlet of the flushing water pump 6 is connected to an external wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com