High-efficiency defective sock splitting device

A technology for socks and defective products, which is applied in the field of high-efficiency defective socks splitting devices, can solve problems such as low work efficiency, and achieve the effect of improving work efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

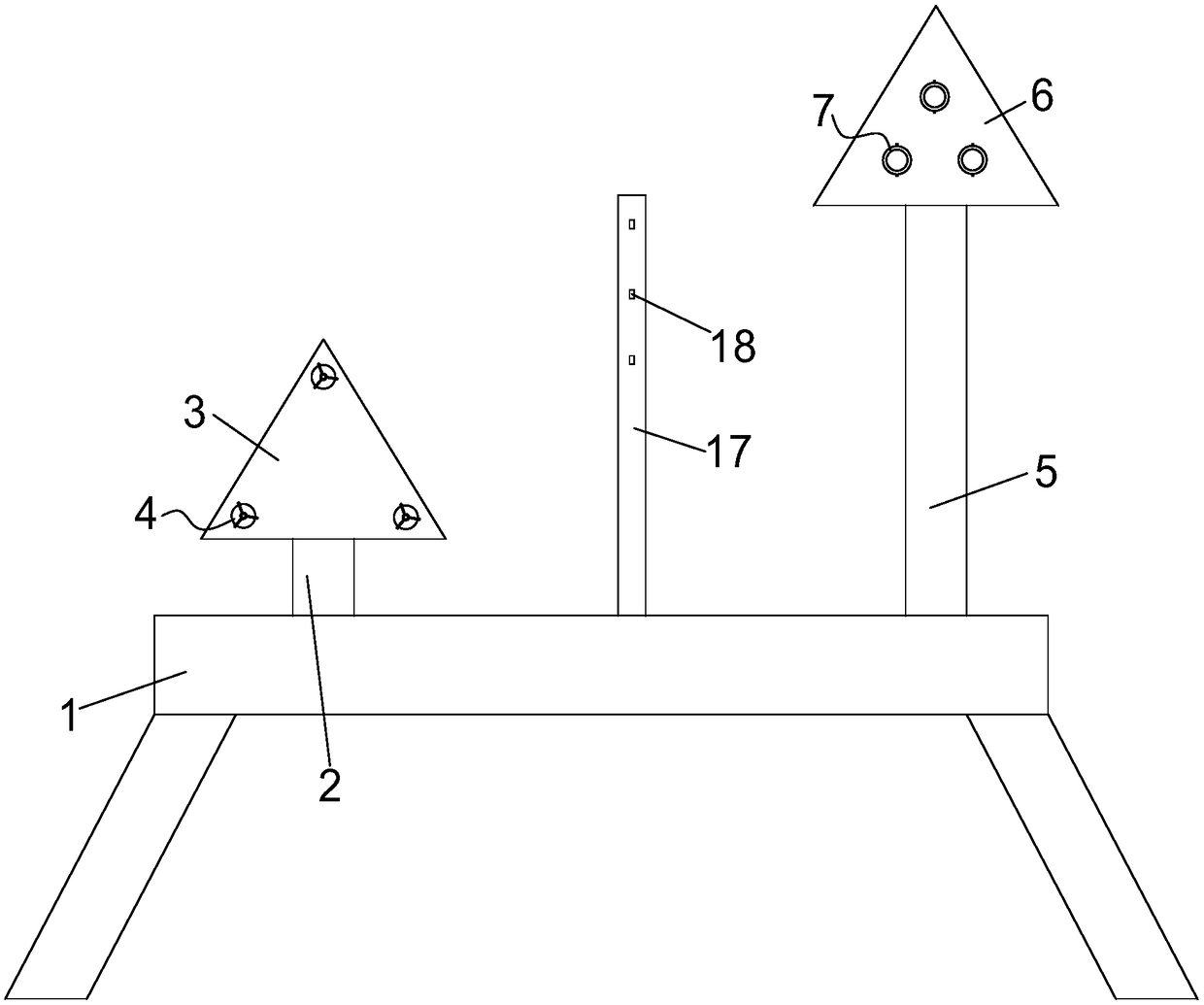

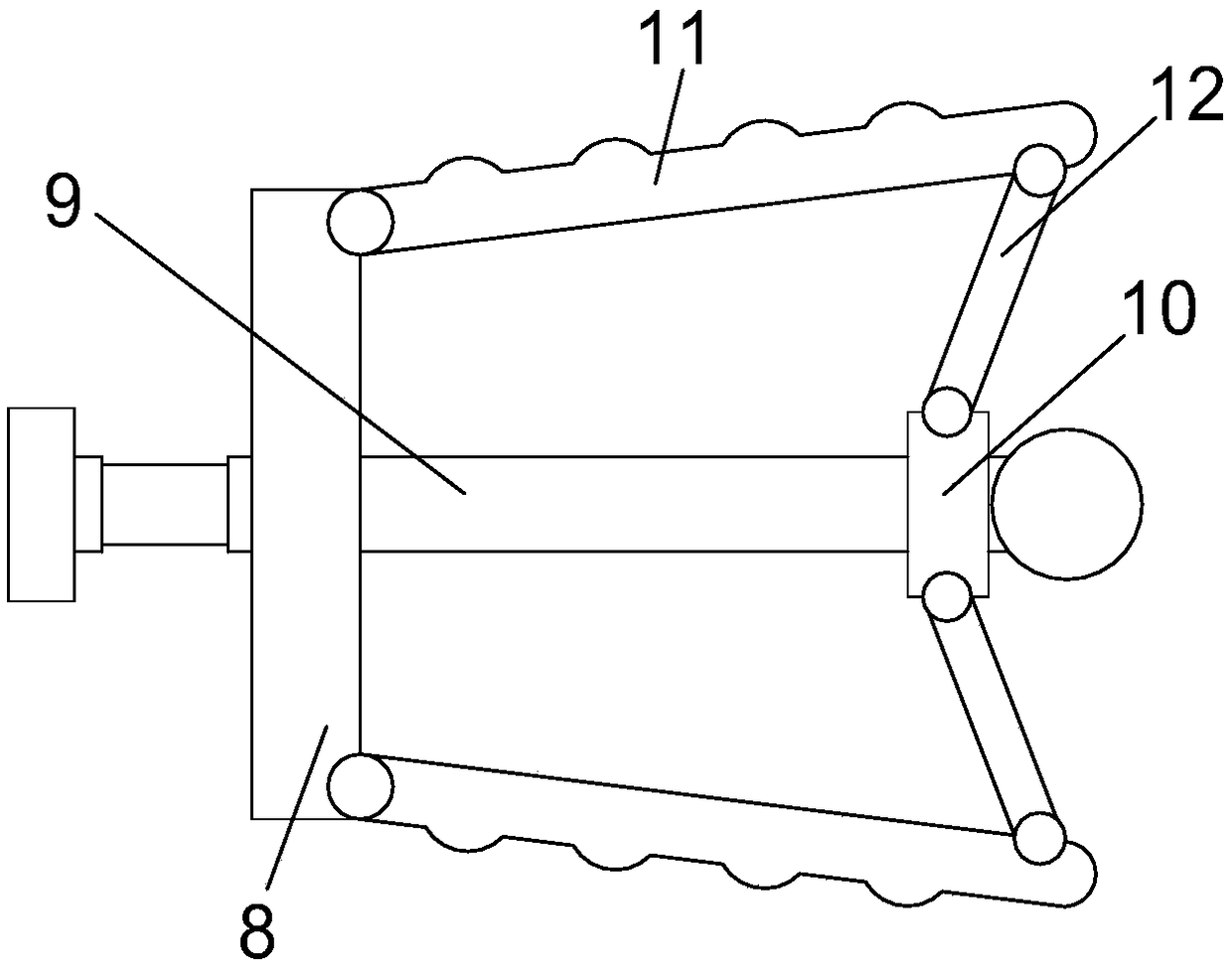

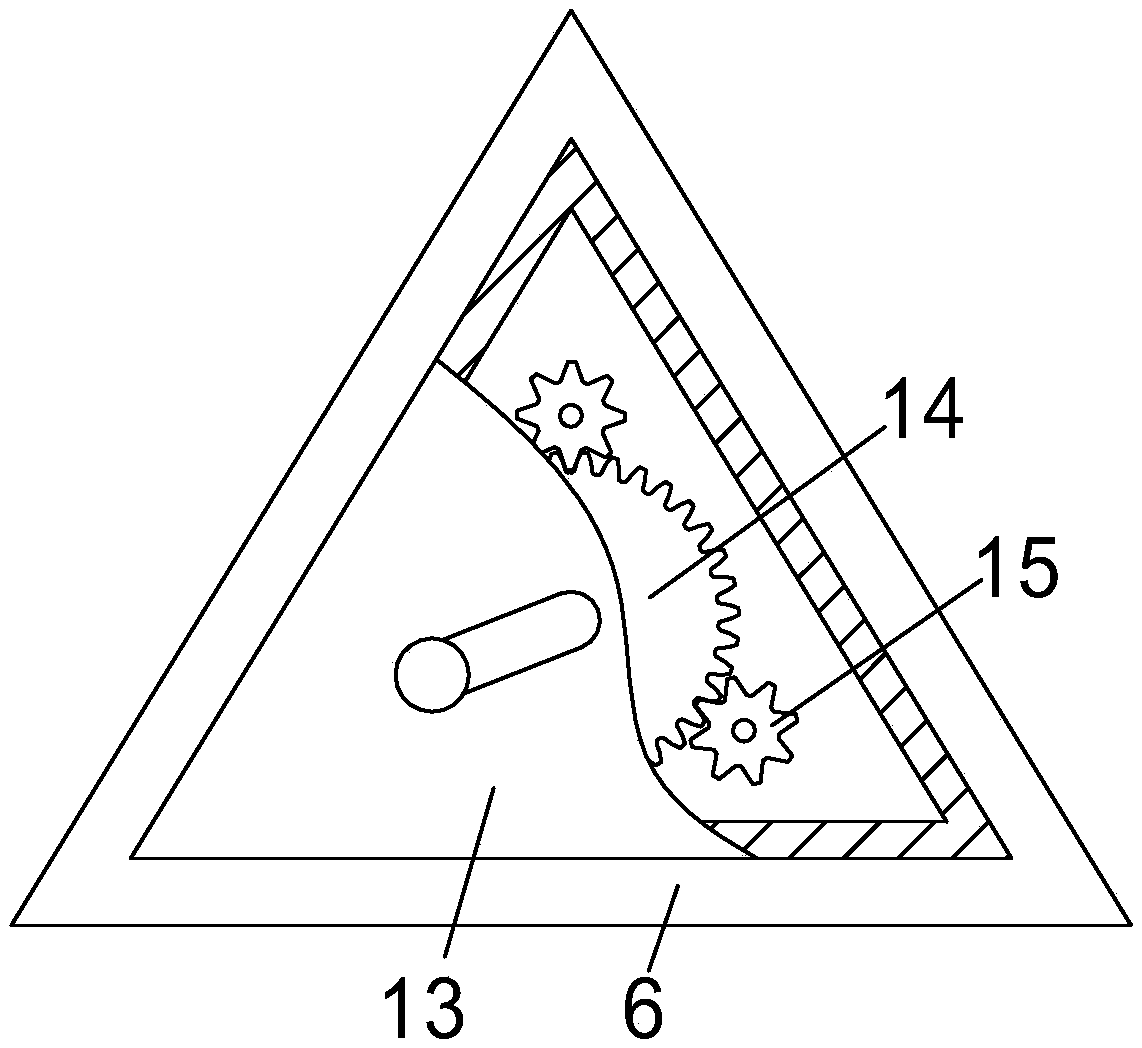

[0019] refer to Figure 1 to Figure 5 As shown: a high-efficiency defective socks splitting device, including a workbench 1, on which a fixed frame and a wire take-up frame are arranged side by side; the fixed frame includes a first triangular mounting plate 3 connected by a first support rod 2, Rotate on the first triangular mounting plate 3 and be provided with three telescopic adjustment fixed claws 4 for fixing socks; There are three take-up barrels 7 for rotation, and the three take-up barrels 7 are provided with a drive mechanism that drives them to rotate simultaneously; the telescopic adjustment fixed claw 4 includes a connecting plate 8 that is both rotatably clamped on the first triangular mounting plate 3, Connecting plate 8 is threadedly connected with screw mandrel 9, and one end of screw mandrel 9 passes through first triangular mounting plate 3 and is locked in rotation with first triangular mounting plate 3, and the other end of screw mandrel 9 is threadedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com