Counterweight device for detecting ballast test through engineering pile foundation

A technology of counterweight device and engineering pile, which is applied in the test of foundation structure, foundation structure engineering, construction, etc. It can solve the problems of scratches on the load-bearing box, counterweight boxes that cannot be tightly embedded with each other, and a single type of storage slot. , to achieve the effect of improving service life and aesthetics, good safety and assembly, safe and easy to assemble and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

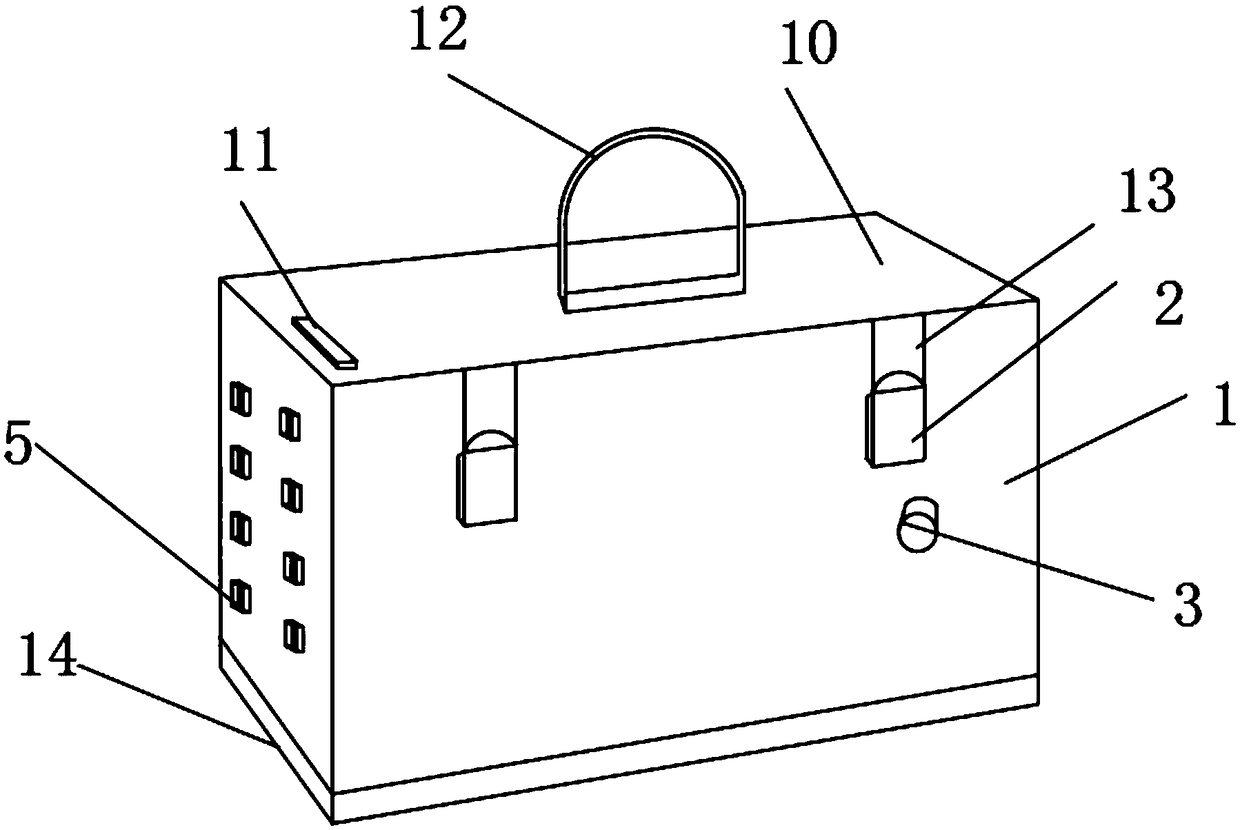

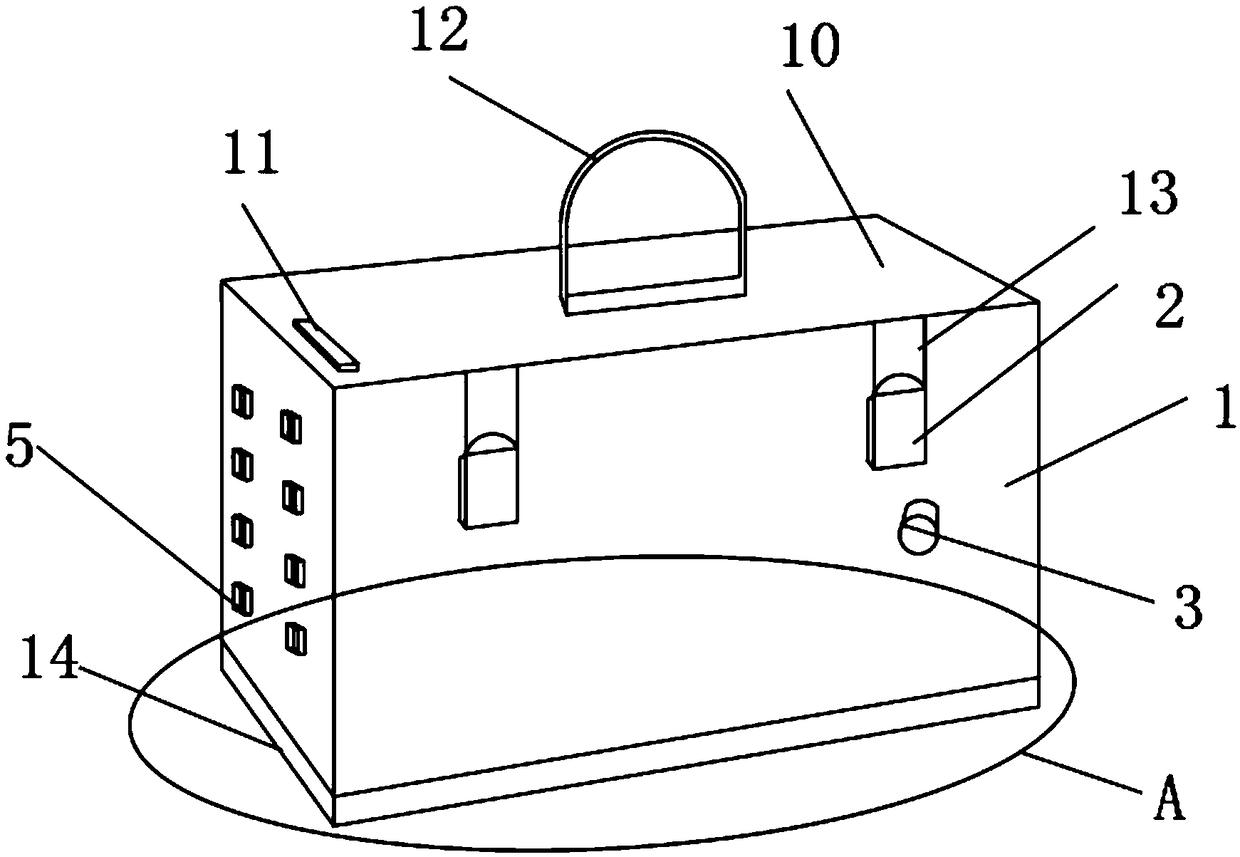

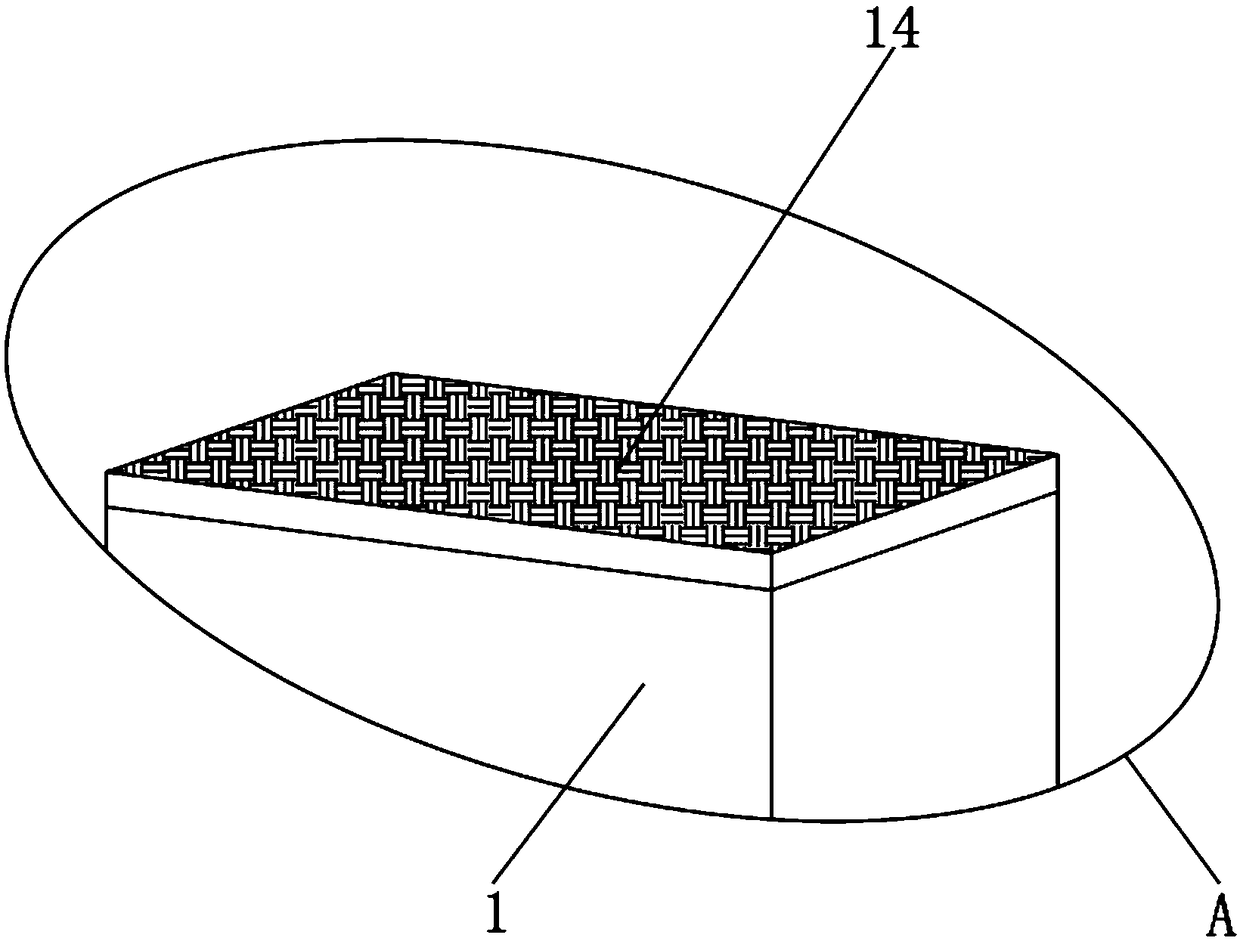

[0019] Such as Figure 1-4 As shown, a counterweight device for engineering pile foundation detection and ballast testing includes a load-bearing box 1 and a control key 11, and a hasp lock 2 is fixedly installed on the outer surface of the load-bearing box 1, and the hasp lock 2 An alarm 3 is provided below, a groove connection port 4 is fixedly installed on one side of the bearing box 1, and a connecting bump 5 is fixedly installed on the other side of the bearing box 1, the bearing box 1 The inner surface is provided with a buffer layer 6, and the inner surface of the buffer layer 6 is provided with a square storage slot 7, and one side of the square storage slot 7 is provided with a circular storage slot 8, and one side of the circular storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com