Plastic bottle clamping and turning mechanism

A technology of turning mechanism and plastic bottles, which is used in conveyor objects, fluid tightness testing, and machine/structural component testing. Production efficiency and other issues, to achieve the effect of improving production and processing efficiency, improving processing efficiency, and avoiding rigid bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

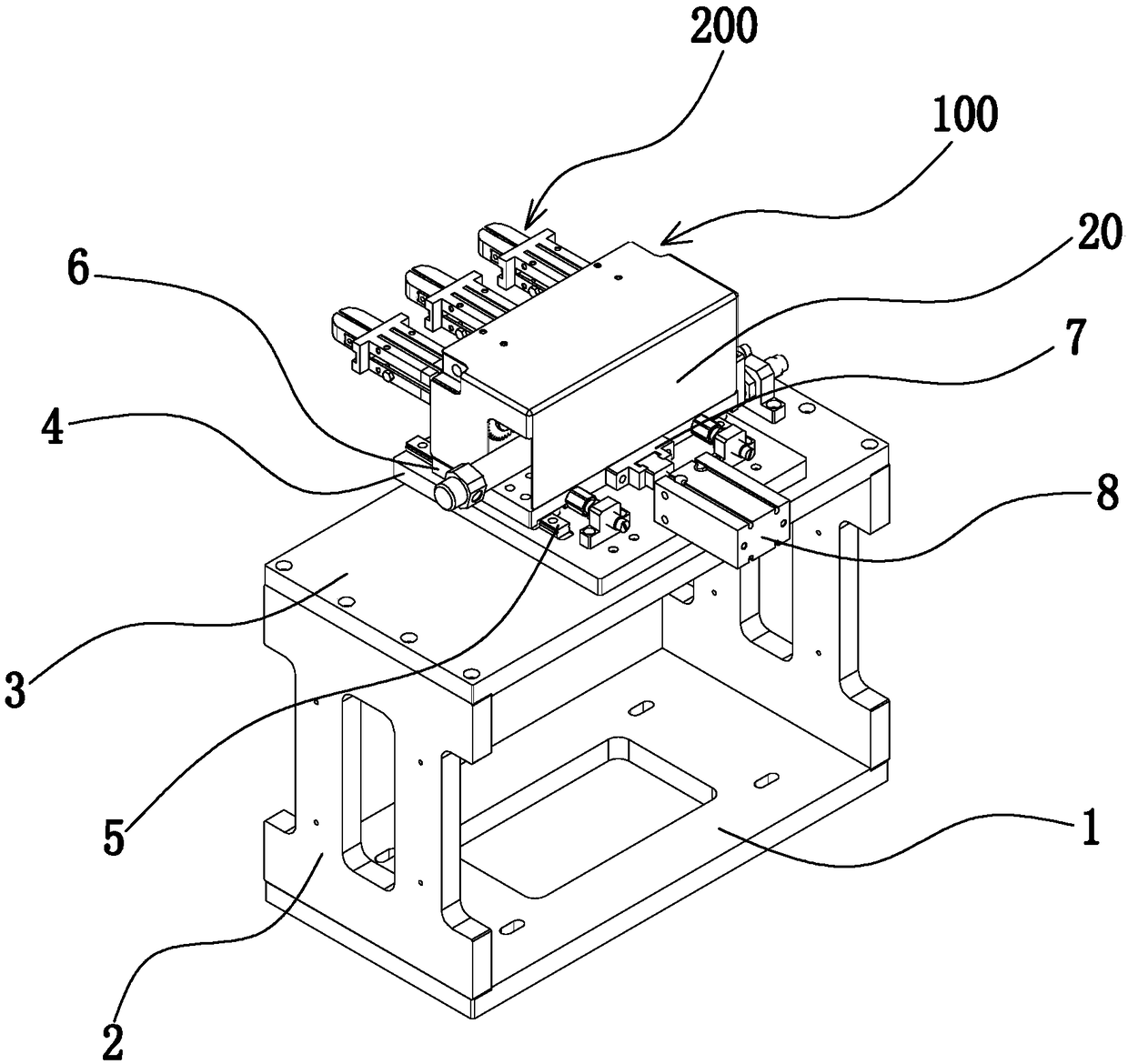

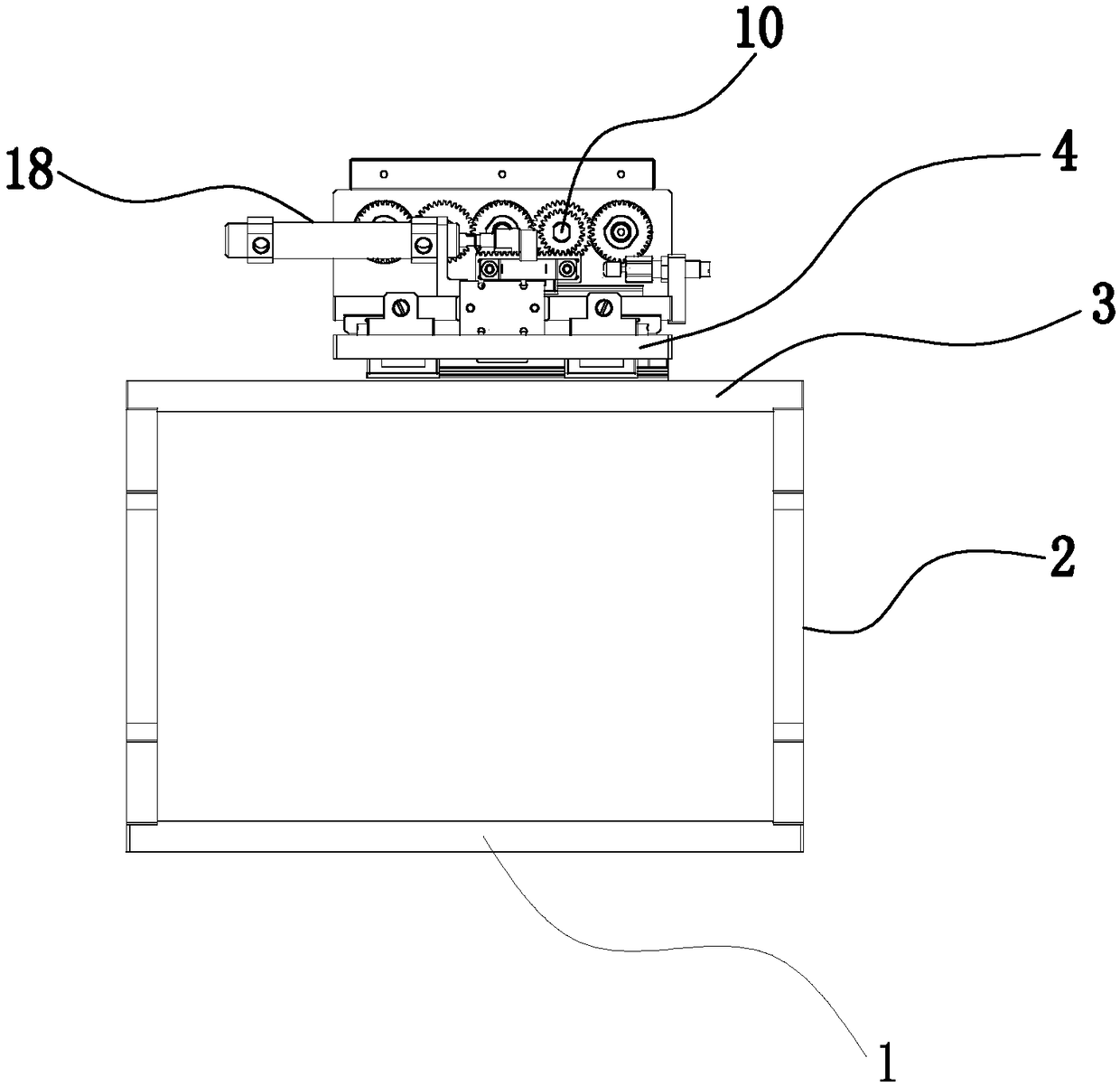

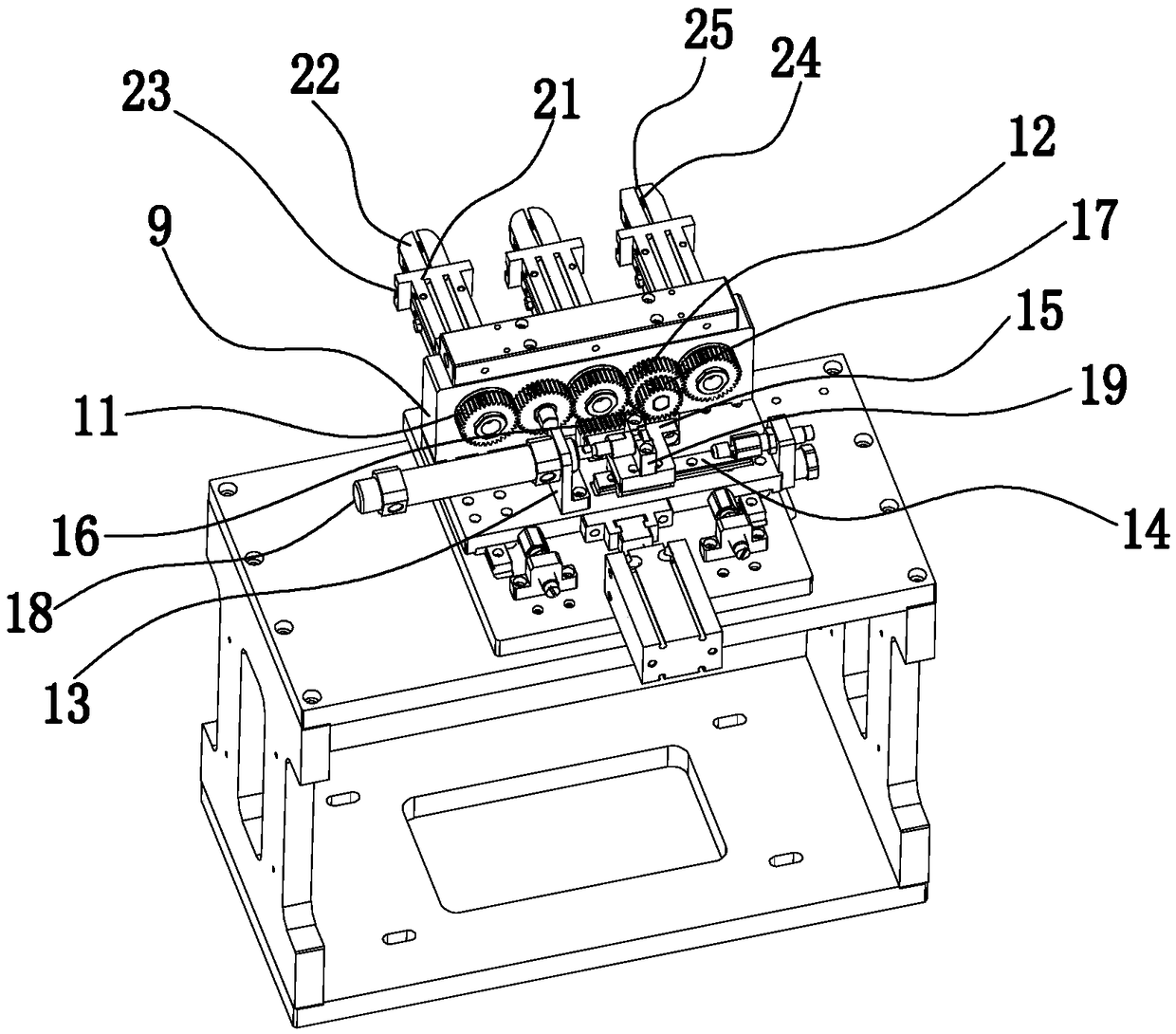

[0025] Example: such as Figure 1-3 As shown, a clamping and turning mechanism for plastic bottles includes a base 1, a support plate 2 fixed on both sides of the base 1, a positioning plate 3 is fixed on the support plate 2, and a connecting plate 4 is provided on the positioning plate 3. Two symmetrical longitudinal guide rails 5 are fixed on the connecting plate 4, and the longitudinal guide rails 5 are arranged along the width direction of the connecting plate 4. There is a clamping and turning mechanism 100 for clamping plastic bottles; this device can replace manual clamping and turning actions on plastic bottles, and can be used with plastic bottles of different sizes and specifications to realize different ways of moving plastic bottles and improve production and processing. In addition, the clamping device in this device is flexible clamping, which can completely avoid the rigid collision between the device and the plastic bottle during the clamping process, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com