Soft film replacement and nanoimprinting integrated equipment

A nano-imprinting and soft film technology, applied in optomechanical equipment, optics, instruments, etc., can solve problems such as not meeting demand, achieve high space utilization, improve efficiency, and improve moving range and moving speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

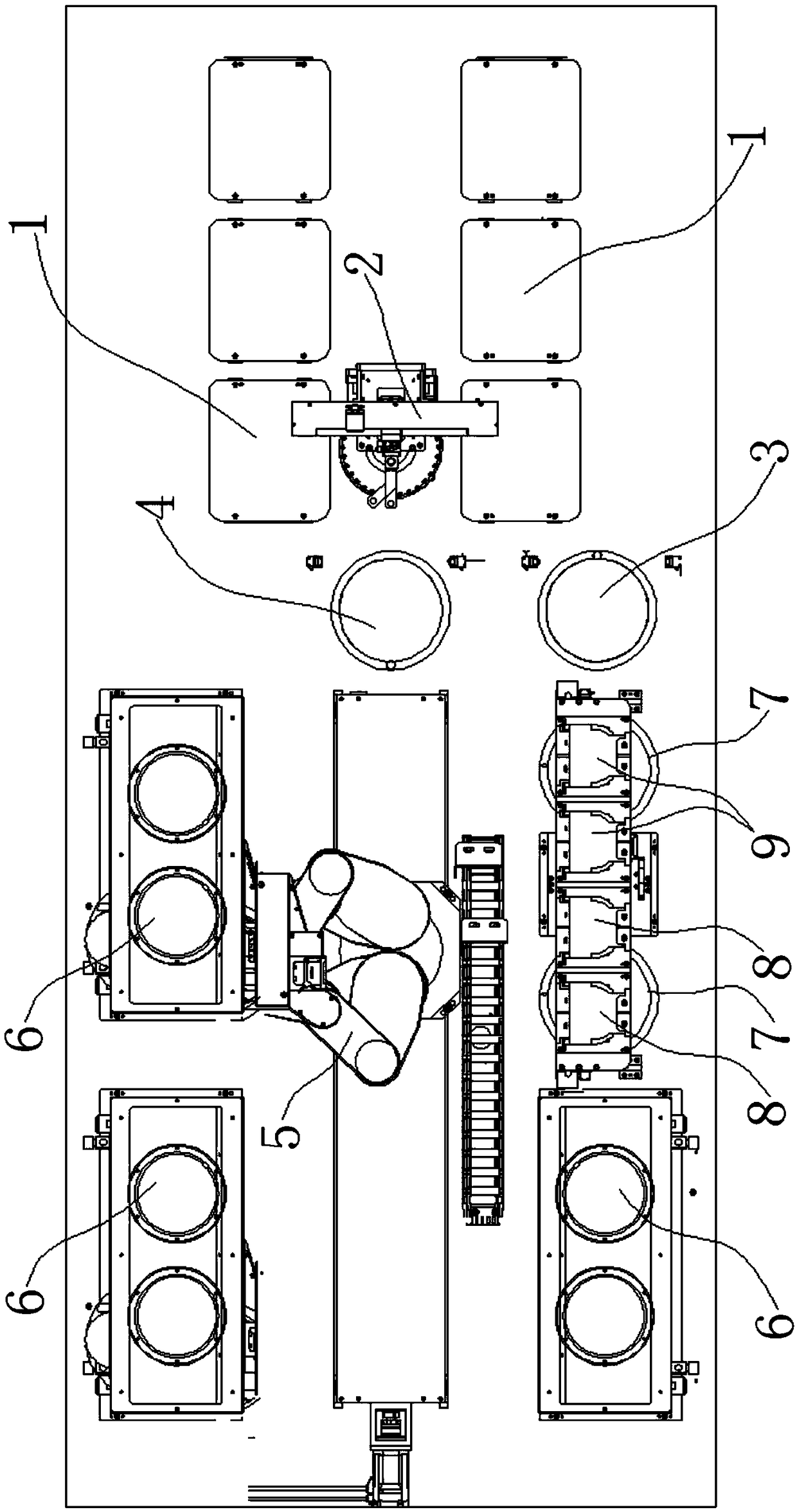

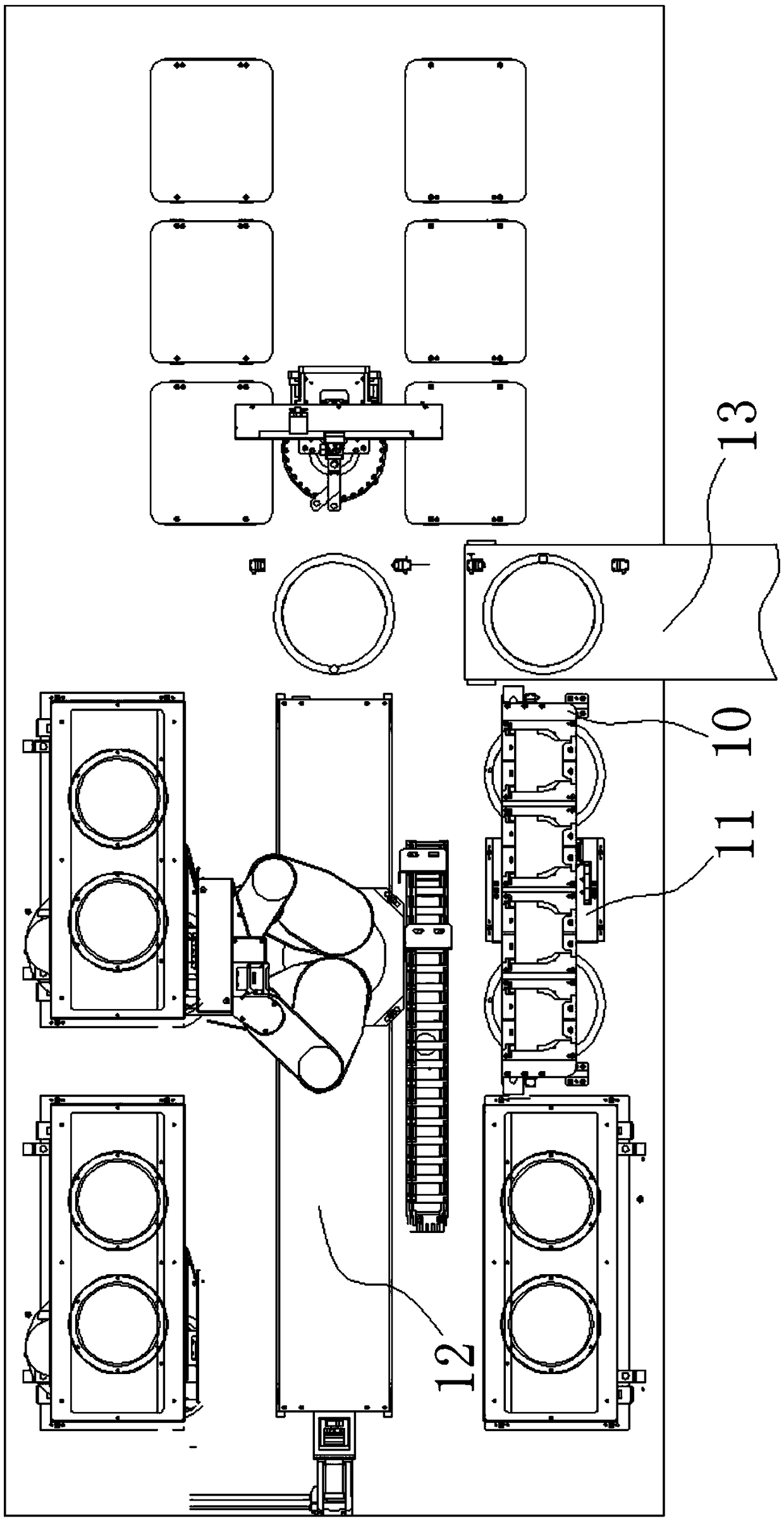

[0030] In order to achieve the purpose of the present invention, a soft film replacement and nano-imprint integrated equipment includes: soft film replication station 1; embossing station 6, several independent embossing stations 1 are used for nano-imprinting, Between the embossing station 6 and the soft film copying station 1, there are a tray storage area 3 and a soft film storage area 4; the stacking frame 10, the embossing station 6 is set as two rows, and the stacking frame 10 is pressed with one row. The printing stations 6 are flush, and the stacking rack 10 is equipped with a wafer storage area and a waste soft film storage area; the retrieving manipulator 5 is set in the middle of two parallel rows of embossing stations 6, and the reclaiming manipulator 5 puts the soft film storage area The soft film on 4 is matched with the carrier plate on the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com