Sole grasping and positioning device for industrial robot

An industrial robot, grasping and positioning technology, applied in footwear, applications, manipulators, etc., can solve the problems of inability to meet performance indicators, bulky, high cost, and achieve large-scale promotion, high intelligence, and low manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

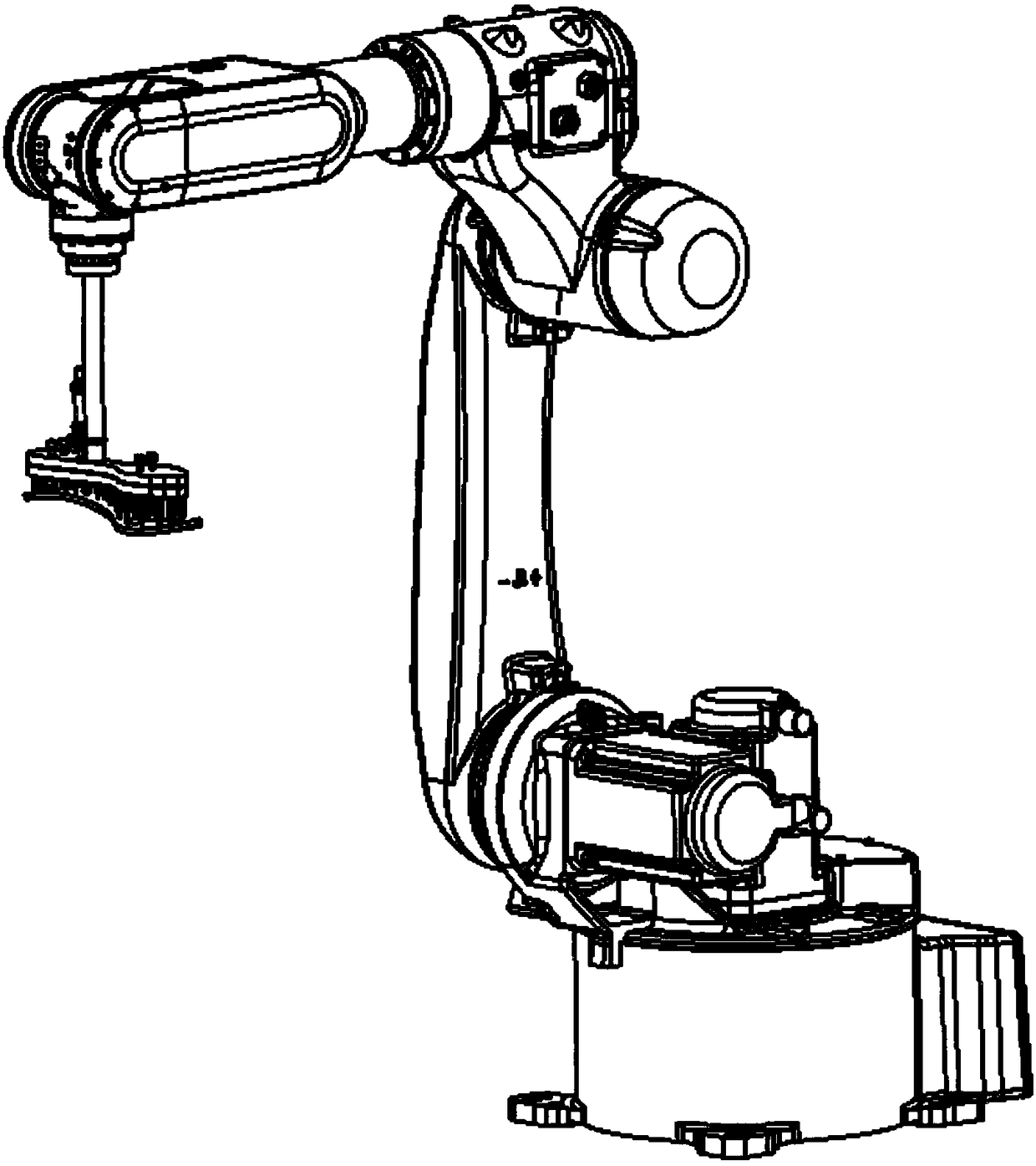

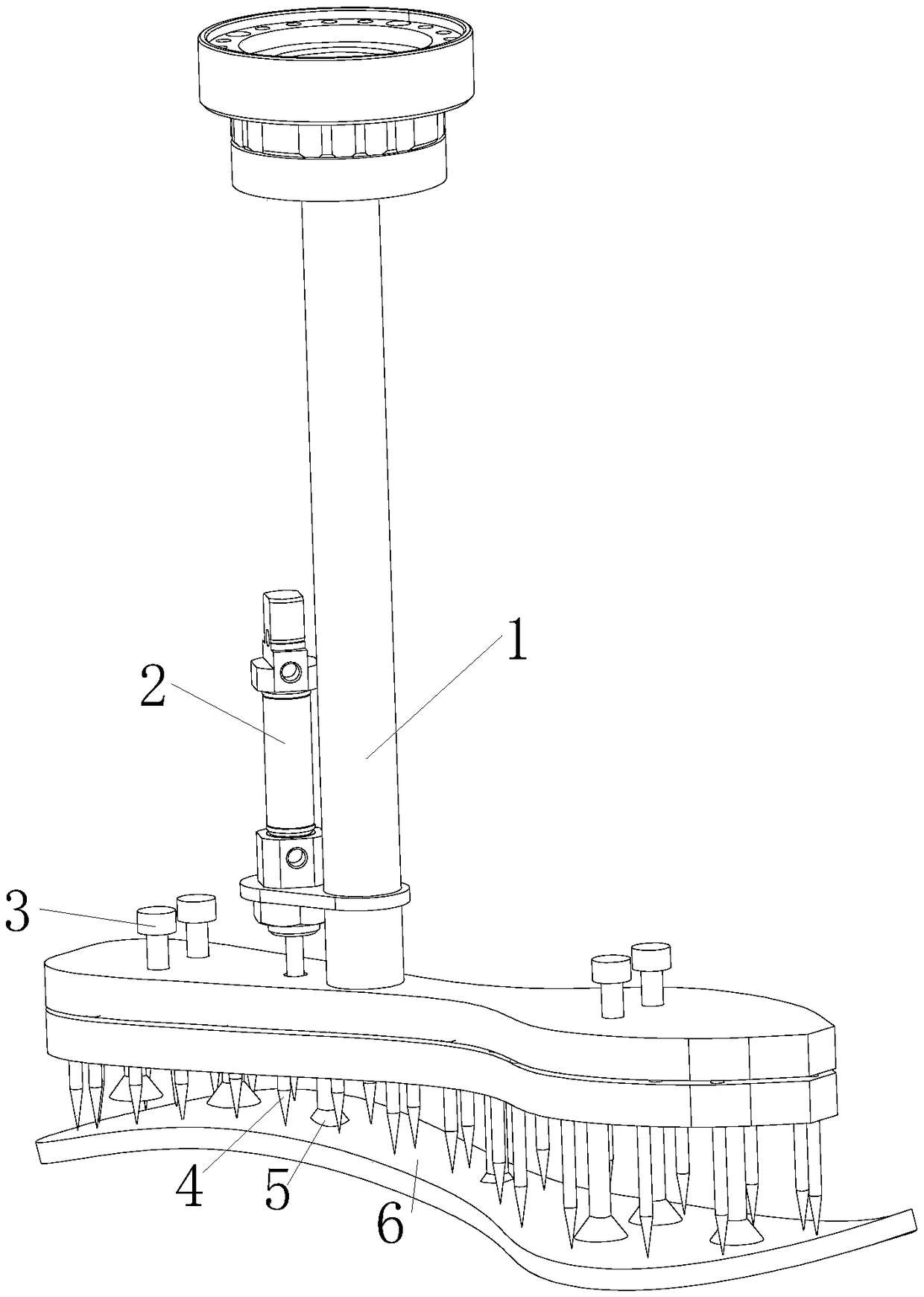

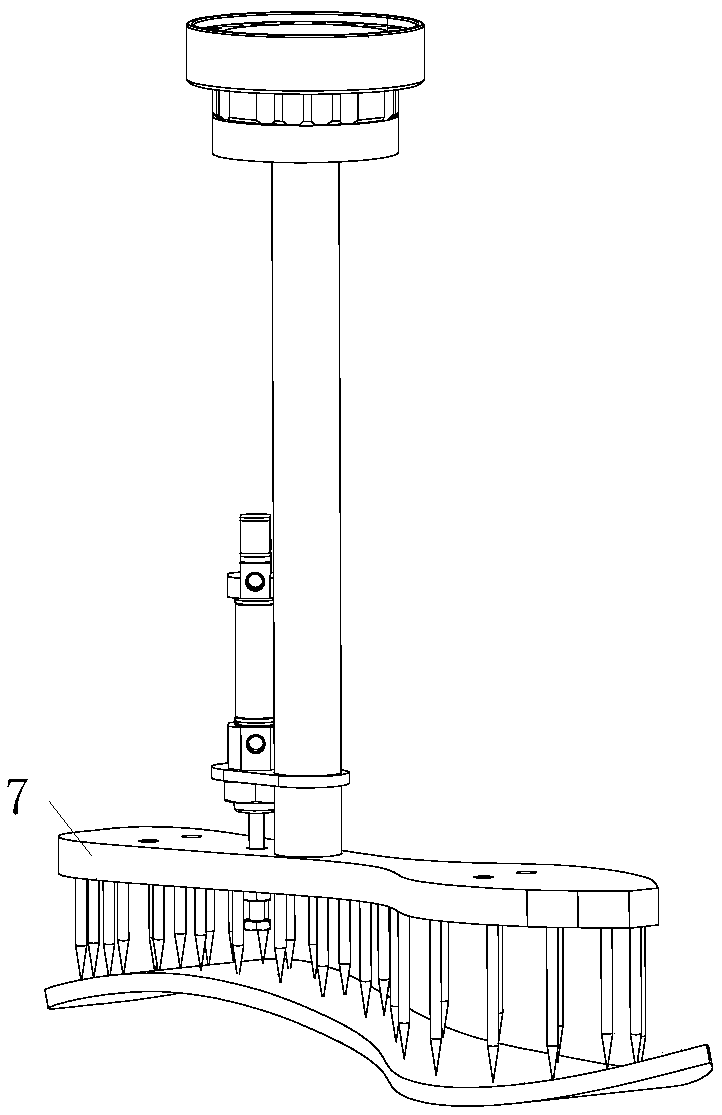

[0020] Such as Figure 1 to Figure 4 Shown, a kind of sole grasping and positioning device for industrial robots includes a connecting rod 1 installed at the end of the industrial robot. The end of the connecting rod 1 far away from the industrial robot has several needles 4, and the connecting rod 1 also has The opening and closing movement can be performed relative to the connecting rod 1 to absorb the adsorption part of the sole 6, and the adsorption part is used to absorb the sole 6 and cooperate with the needle 4 to complete the positioning.

[0021] The connecting rod 1 is provided with a stretching mechanism 2 for completing the opening and closing movement, and the stretching mechanism 2 can be a hydraulic cylinder or an air cylinder.

[0022] The overall movement of the sole 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com