Shoe sole cleaning machine

The technology of a sole cleaning machine and a cleaning tank is applied in the field of shoe cleaning, which can solve the problems of insufficient cleaning force, low service life, complex structure, etc., and achieve the effects of no residue, long service life and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

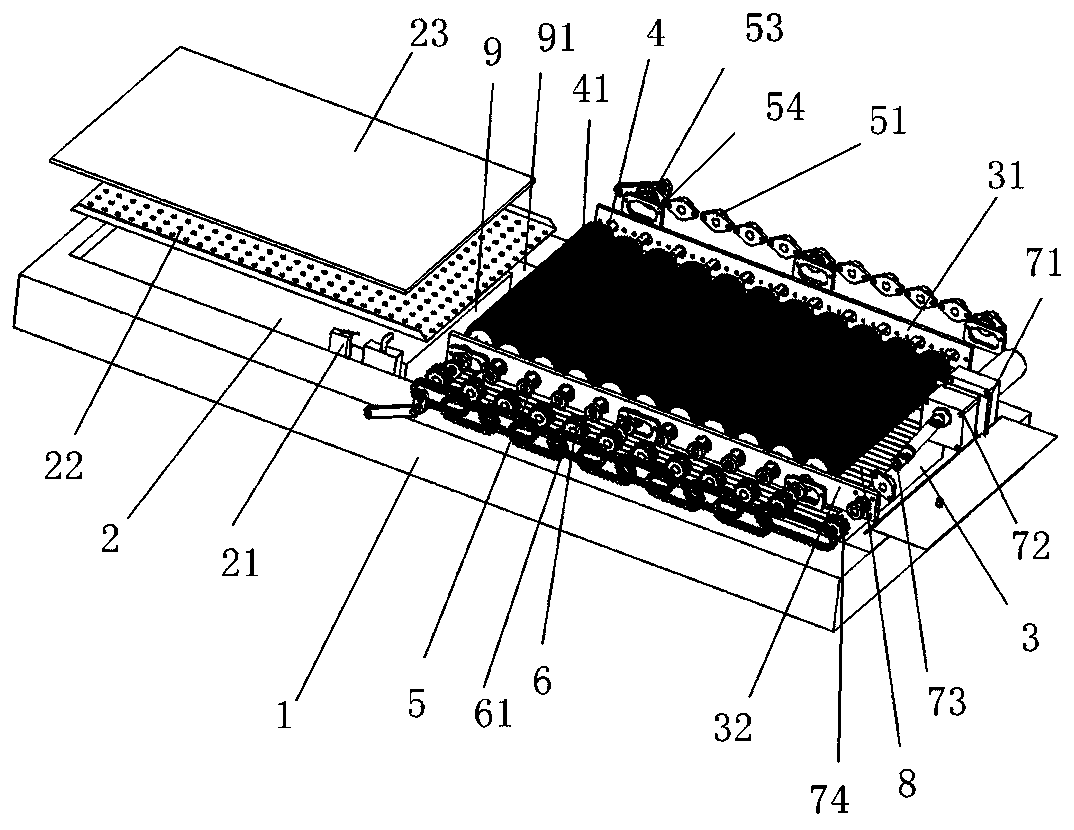

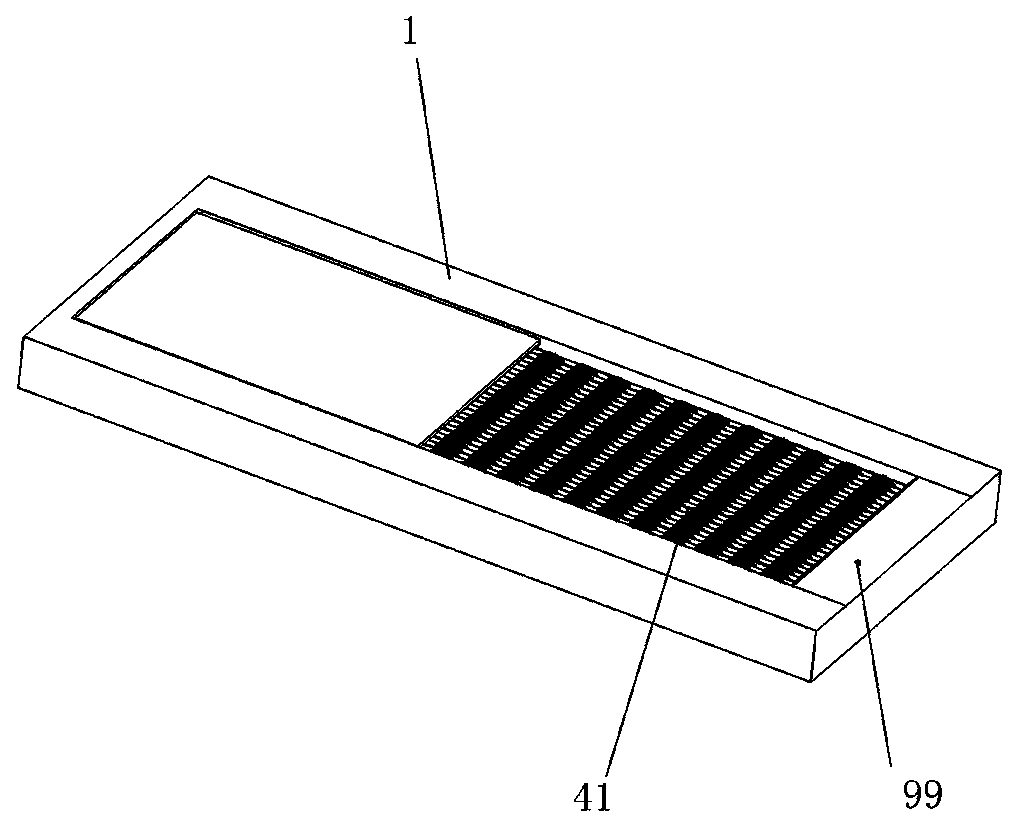

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0017] Such as Figure 1-Figure 2 As shown, a kind of shoe sole cleaning machine of the present invention comprises shell cover 1, and shell cover 1 left side is provided with water tank 2, and shell cover 1 right side is provided with cleaning tank 3, and cleaning tank 3 is provided with cleaning device, cleaning The device includes an upper side translation frame 31 and a lower side translation frame 32 arranged in parallel, a number of rollers 4 are arranged in a regular horizontal arrangement between the upper side translation frame 31 and the lower side translation frame 32, and the top and bottom ends of the rollers 4 are respectively pierced The outer sides of the upper side translation frame 31 and the lower side translation frame 32 are provided with bearings 5, the outer sides of the bearings 5 at the top...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap