Fluidized bed reactor and its application

A fluidized bed reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problem of unfavorable catalyst sample detection and analysis, catalyst screening, no online catalyst extraction, Inefficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Neither the endpoints nor any values of the ranges disclosed herein are limited to such precise ranges or values, and these ranges or values are understood to include values approaching these ranges or values. For numerical ranges, between the endpoints of each range, between the endpoints of each range and individual point values, and between individual point values can be combined with each other to obtain one or more new numerical ranges, these values Ranges should be considered as specifically disclosed herein.

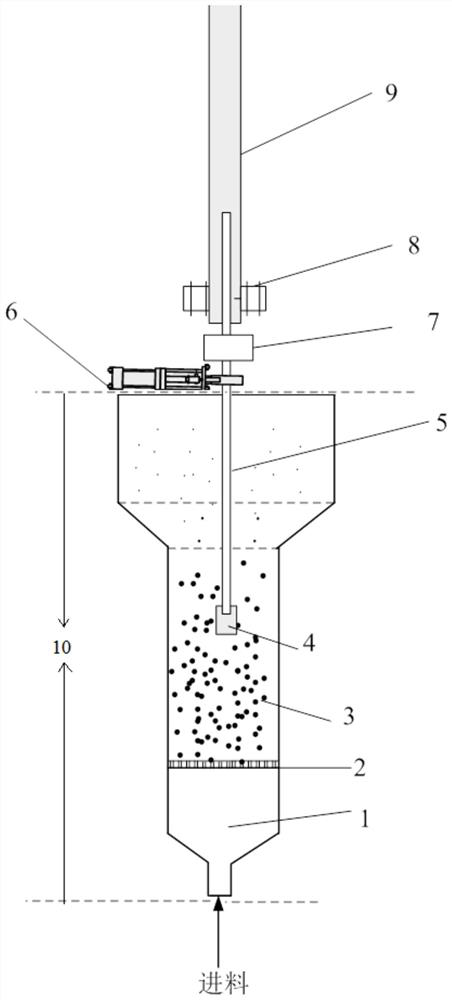

[0012] One aspect of the present invention provides a fluidized bed reactor, which includes a reaction device 10 and a catalyst extracting device arranged on the reactor for extracting catalyst online.

[0013] According to the present invention, it can be understood that the fluidized bed reactor of the present invention is equipped with the catalyst extracting device of the present invention on the basis of a common fluidized bed reactor, and by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com