Electric vehicle battery replacement system and method

A battery replacement and electric vehicle technology, applied in electric vehicles, electric power devices, charging stations, etc., can solve the problems of cumbersome battery disassembly and assembly procedures, inability to meet customer needs in time, and long charging time, so as to facilitate maintenance and replacement. , the effect of reducing labor intensity and improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

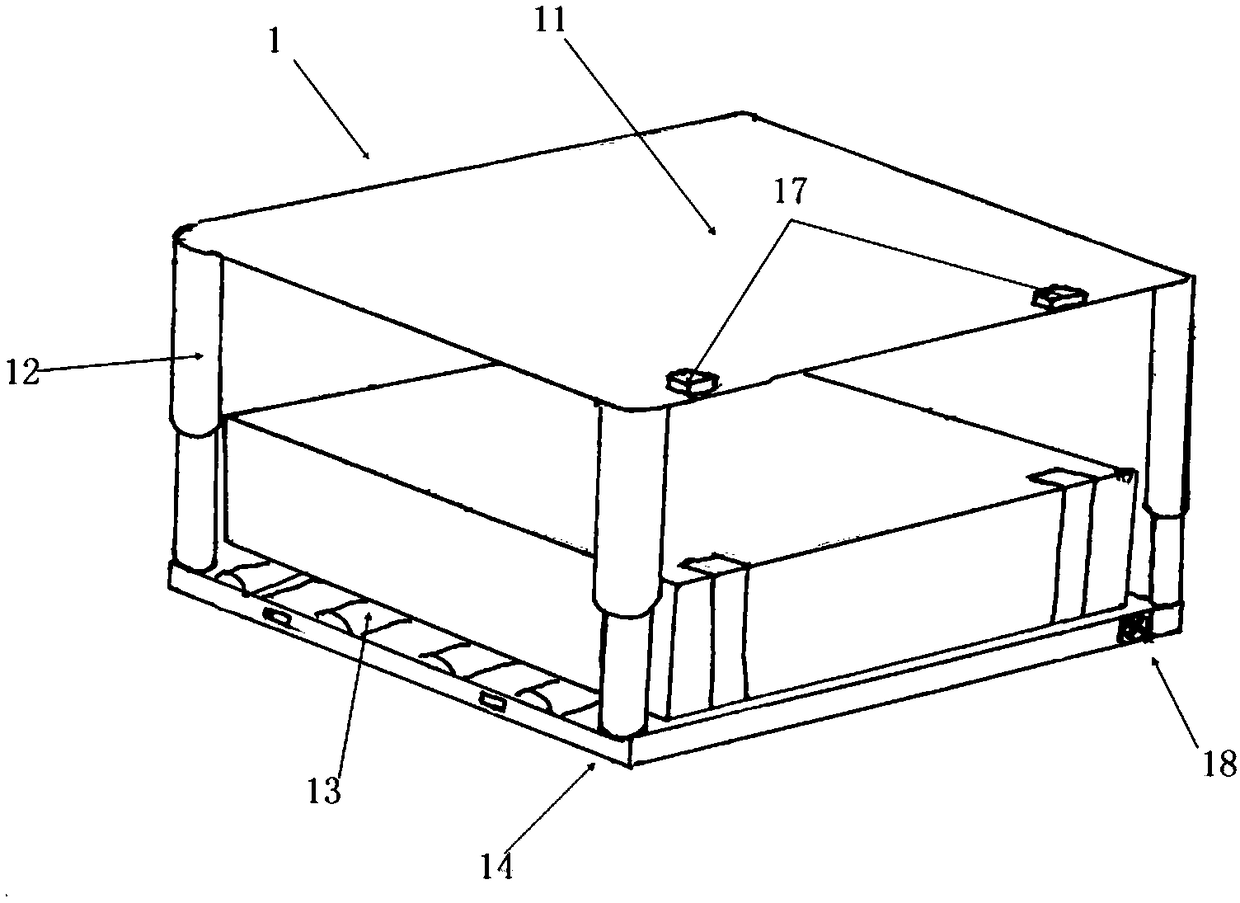

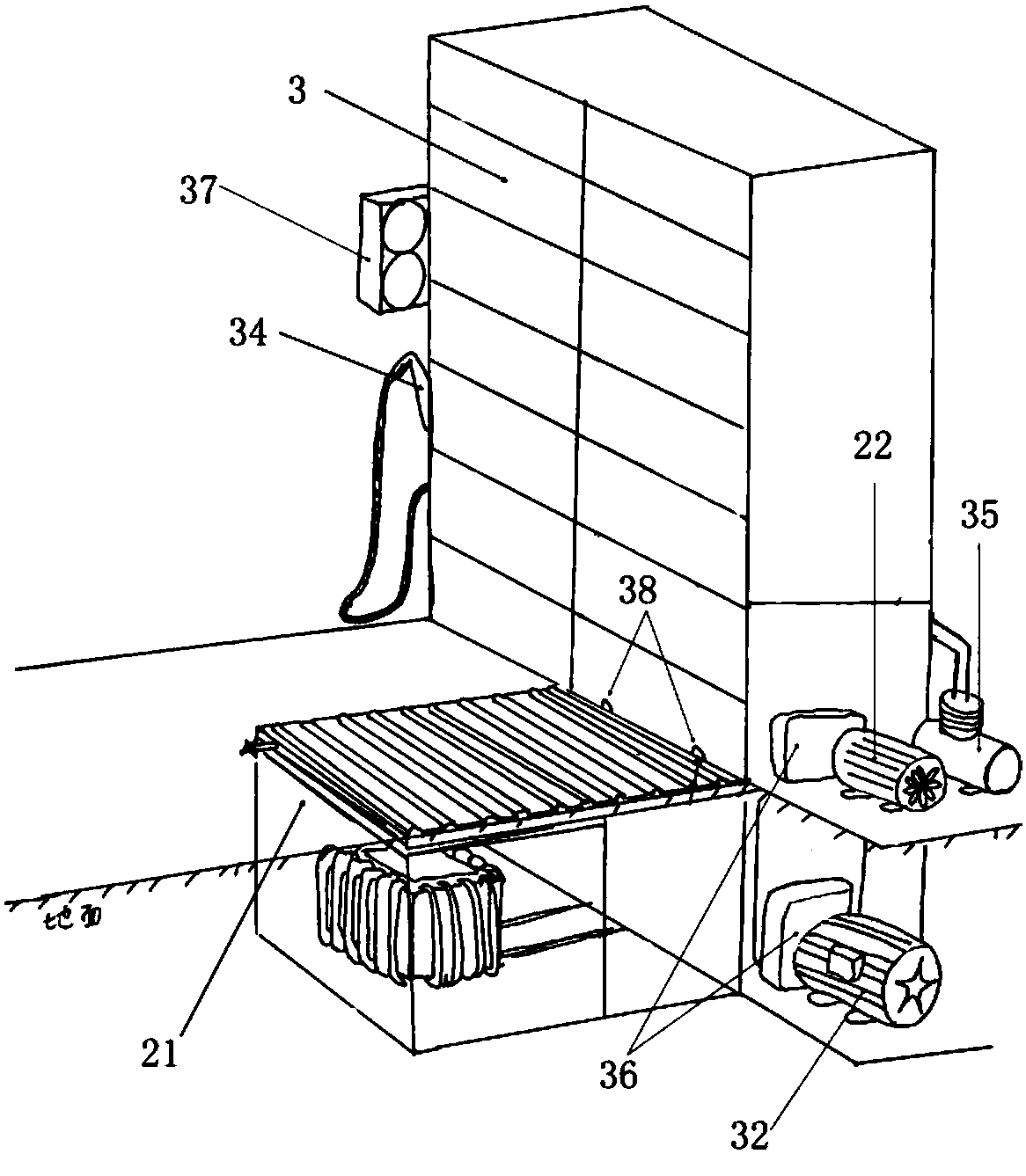

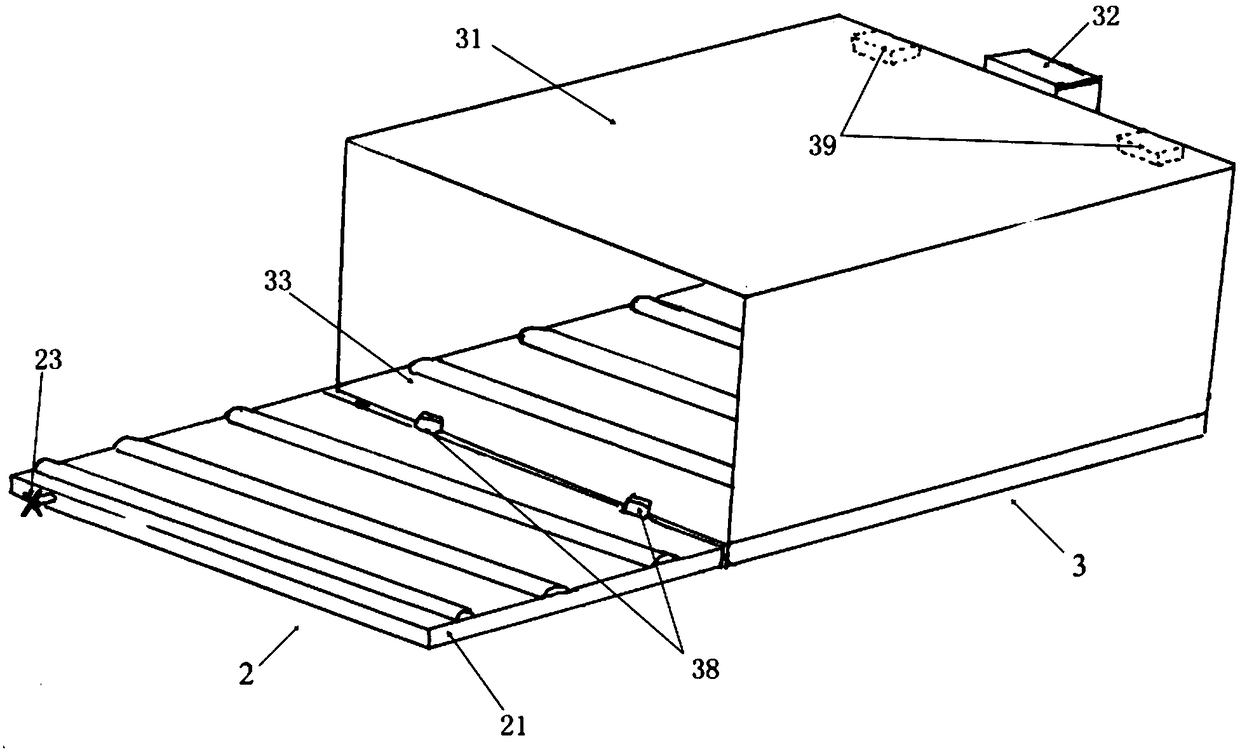

[0023] figure 1 A schematic structural view showing the battery compartment 11 in an open state, figure 2 A schematic diagram of the installation structure of the delivery device 2 and the replacement device 3 is shown, image 3 A schematic diagram of the connection between the rechargeable battery compartment and the second lead-in and lead-out part is shown, Figure 4 A schematic diagram of the structure of the battery is shown. The battery replacement system includes a vehicle-mounted device 1 , a delivery device 2 and a replacement device 3 .

[0024] Wherein, the vehicle-mounted device 1 includes a battery compartment 11 for accommodating batteries, a lifting column 12 and a first lead-in and export portion 13, the battery compartment 11 is arranged on the bottom of the vehicle body; one end of the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com