Magnetic bead cleaning method and device

A magnetic bead cleaning and cleaning technology, applied in the field of sample analysis, can solve problems such as inaccurate experimental results, and achieve the effect of avoiding carryover pollution and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

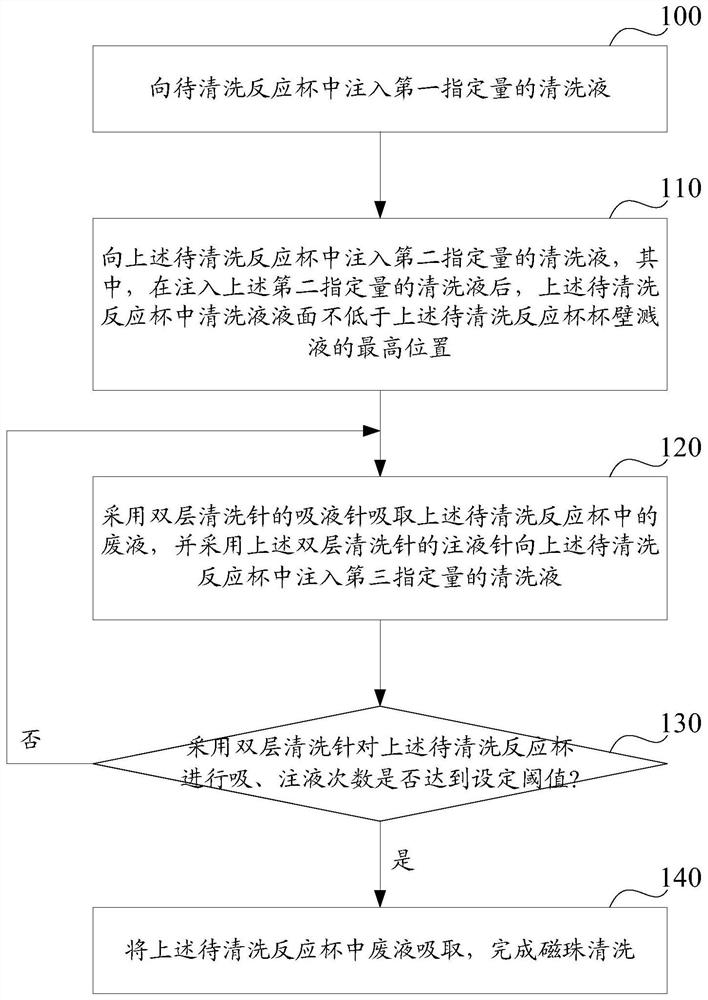

Method used

Image

Examples

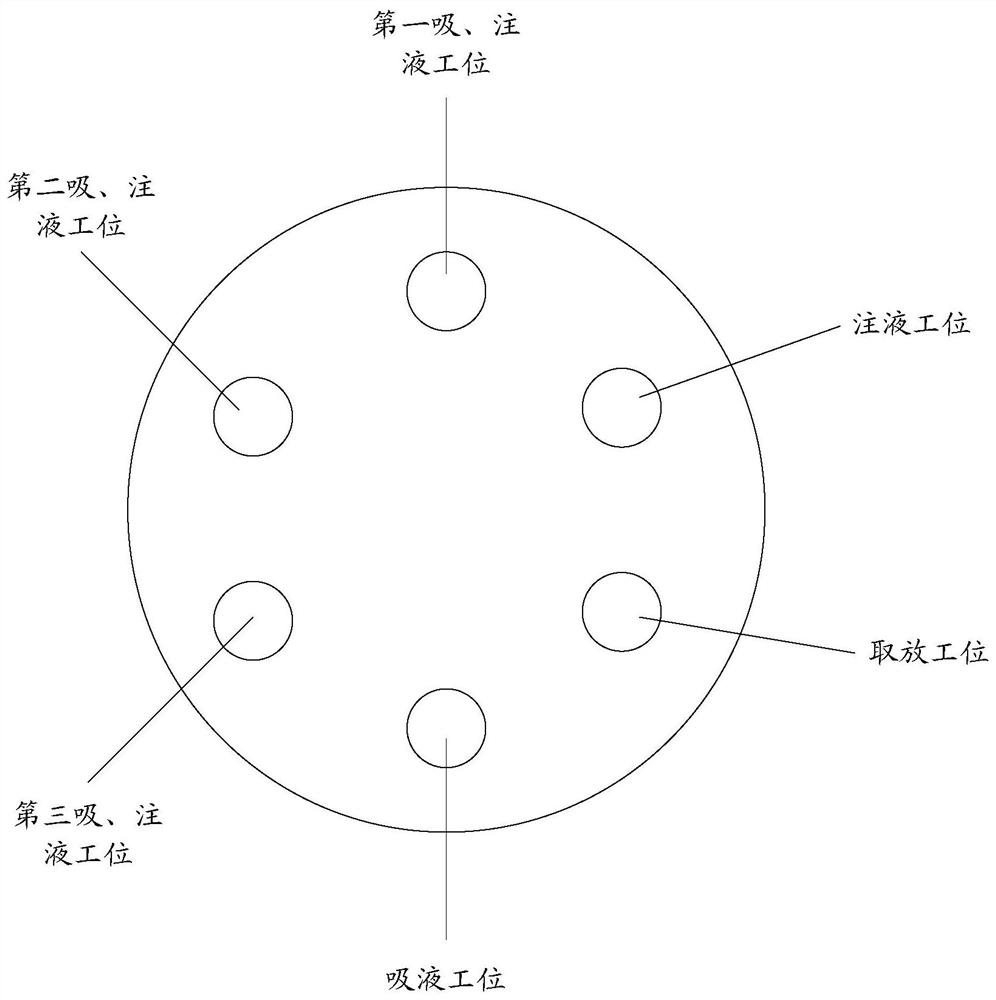

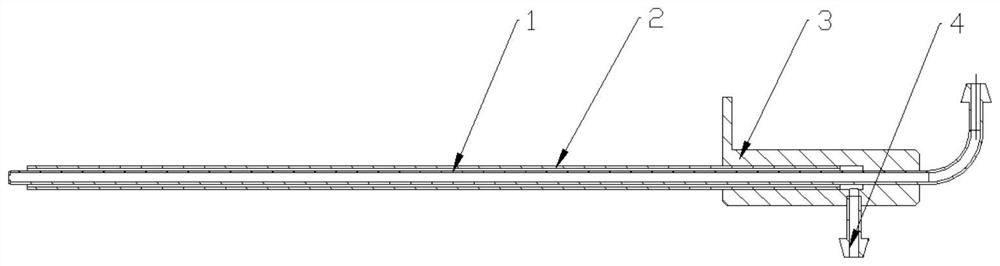

Embodiment Construction

[0036] In order to facilitate the understanding of the technical solutions introduced in the embodiments of the present invention, definitions of some terms are given here:

[0037] 1. Magnetic bead washing refers to the method of washing away the substances in the reaction solution that are not bound to the solid-phase antigen and antibody, as well as the interfering substances that are non-specifically adsorbed on the solid-phase carrier during the reaction process.

[0038] 2. The magnetic adsorption operation refers to the operation of making the magnetic beads adsorb on the wall of the cuvette corresponding to the magnetic adsorption unit through the magnetic adsorption unit.

[0039] 3. The liquid injection needle refers to the single cleaning needle only used for liquid injection operation; the liquid suction needle refers to the single cleaning needle used only for liquid suction operation.

[0040] 4. The double-layer cleaning needle refers to the cleaning needle incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com