Convenient to dismount electromechanical integration punching device

A punching device and electromechanical technology, applied in the field of mechanical equipment, can solve the problems of no supporting function, inconvenient fixation, no cleaning, etc., and achieve the effect of increasing functions, easy adjustment, and convenient punching work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

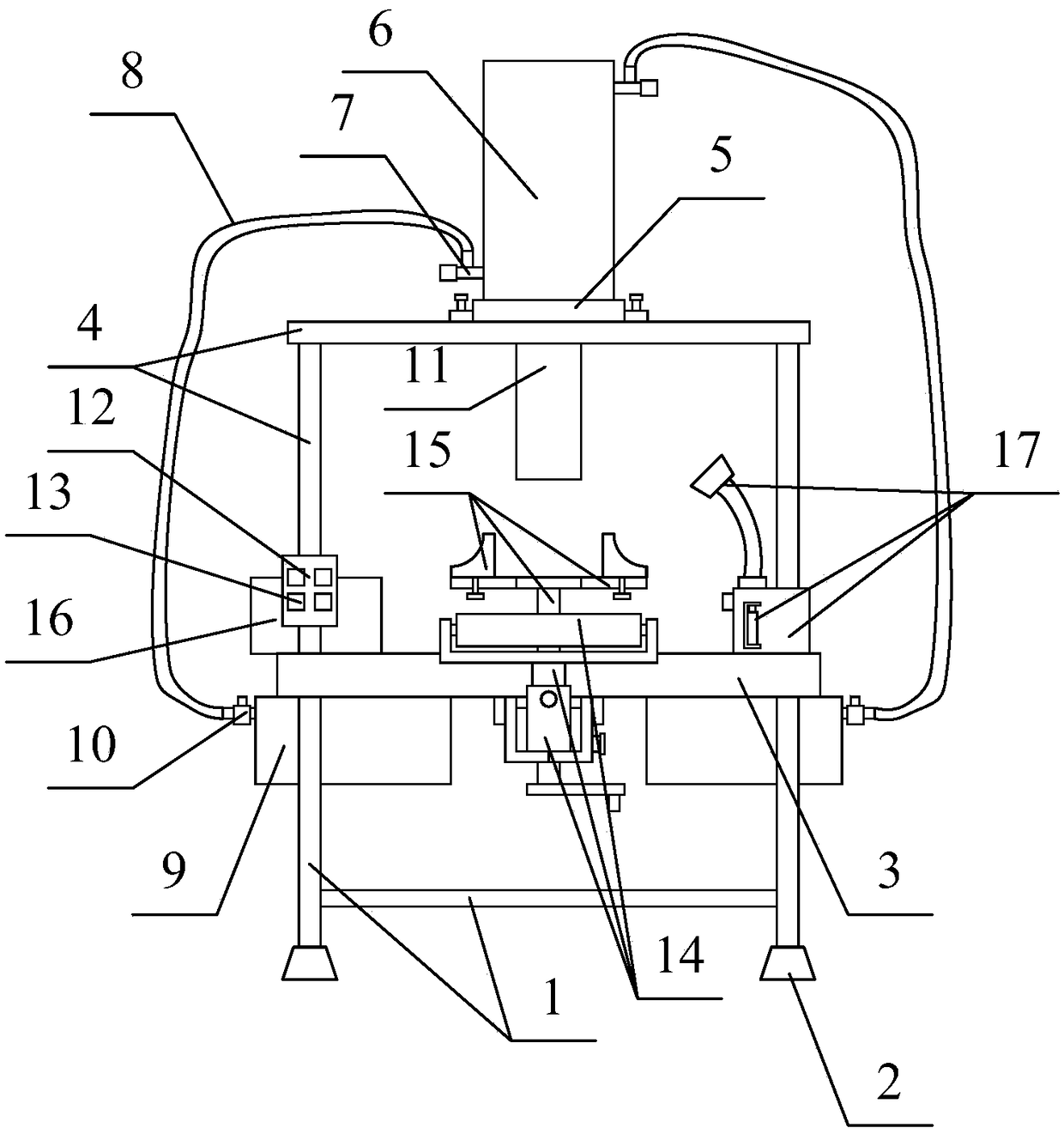

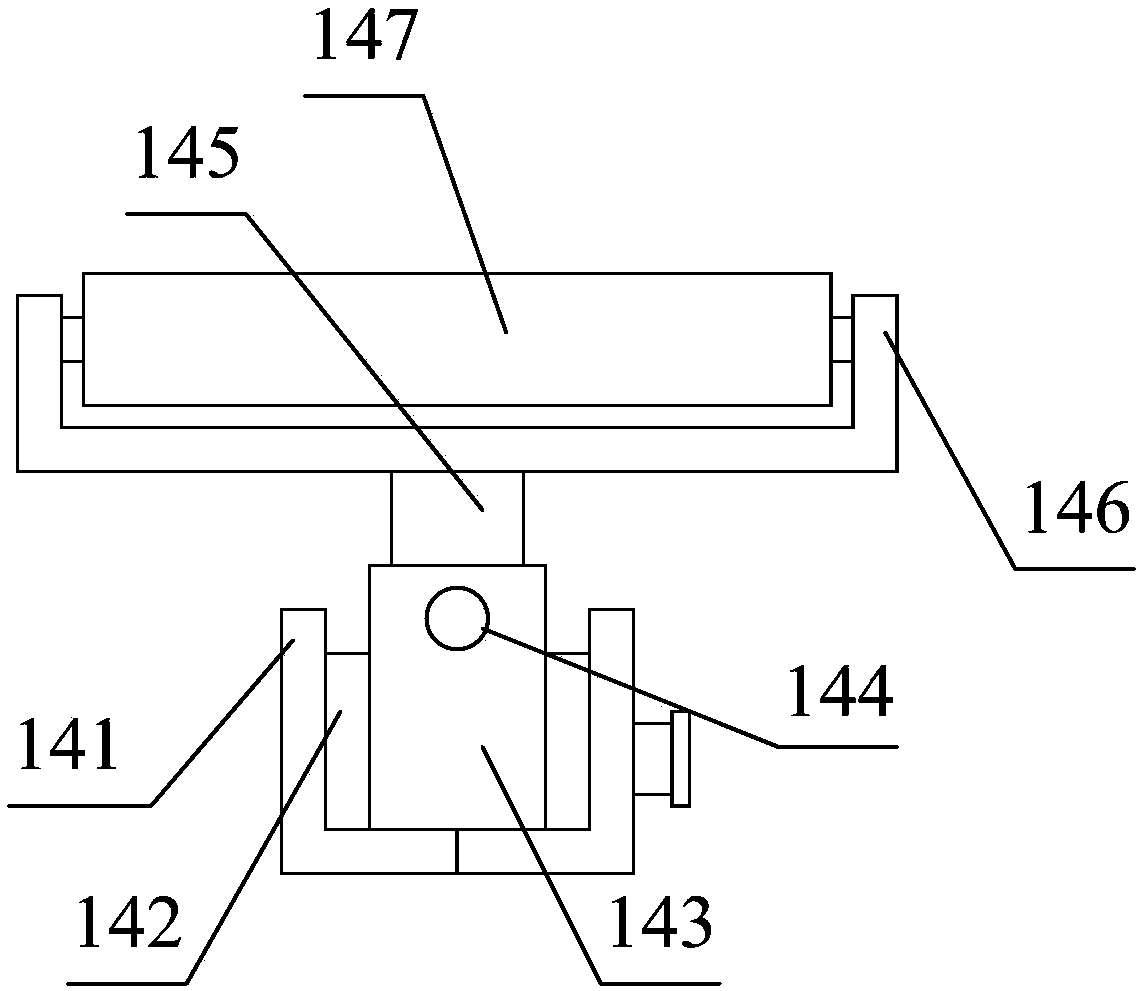

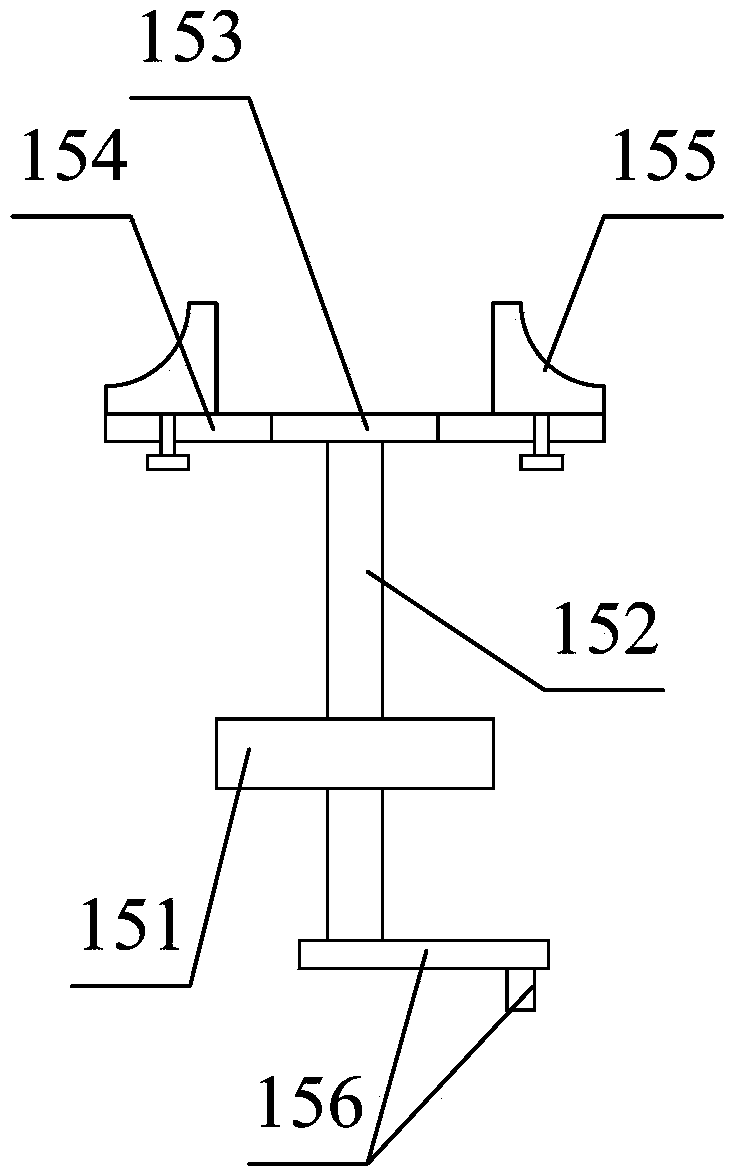

[0039] as attached figure 1 And attached figure 2 As shown, a mechatronic punching device that is easy to disassemble includes a fastening frame 1, an anti-slip sleeve 2, a working plate 3, a fixing frame 4, a connecting seat 5, a cylinder 6, a connecting head 7, an oil delivery pipe 8, and an oil storage tank 9 , oil pump 10, stamping rod 11, distribution box 12, button 13, support frame structure 14, fixed plate structure 15, air duct structure 16 and lighting box structure 17, the anti-slip sleeve 2 is sleeved on the fastening frame 1 The lower end; the left and right sides of the upper and lower surfaces of the working plate 3 are respectively welded with a fixed frame 4 and a fastening frame 1; The interior of the cylinder is inlaid with a cylinder 6; the connecting head 7 is integrally arranged on the lower left and upper right parts of the outer wall of the cylinder 6; one end of the oil delivery pipe 8 is sleeved on the outer wall of the connecting head 7, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com