Fusion penetration control method for fillet joints based on near-infrared binocular vision recognition

A technology of binocular visual recognition and fillet joint, which is applied in the field of penetration control of fillet joints based on near-infrared binocular visual recognition, can solve the problems of affecting the fusion width of the reverse side, image arc interference, etc., and achieves rich information and images. Clear, high practical value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention more clear and definite, the present invention will be further stated below in conjunction with the accompanying drawings and specific embodiments. The following examples serve to illustrate the invention, but do not limit the invention.

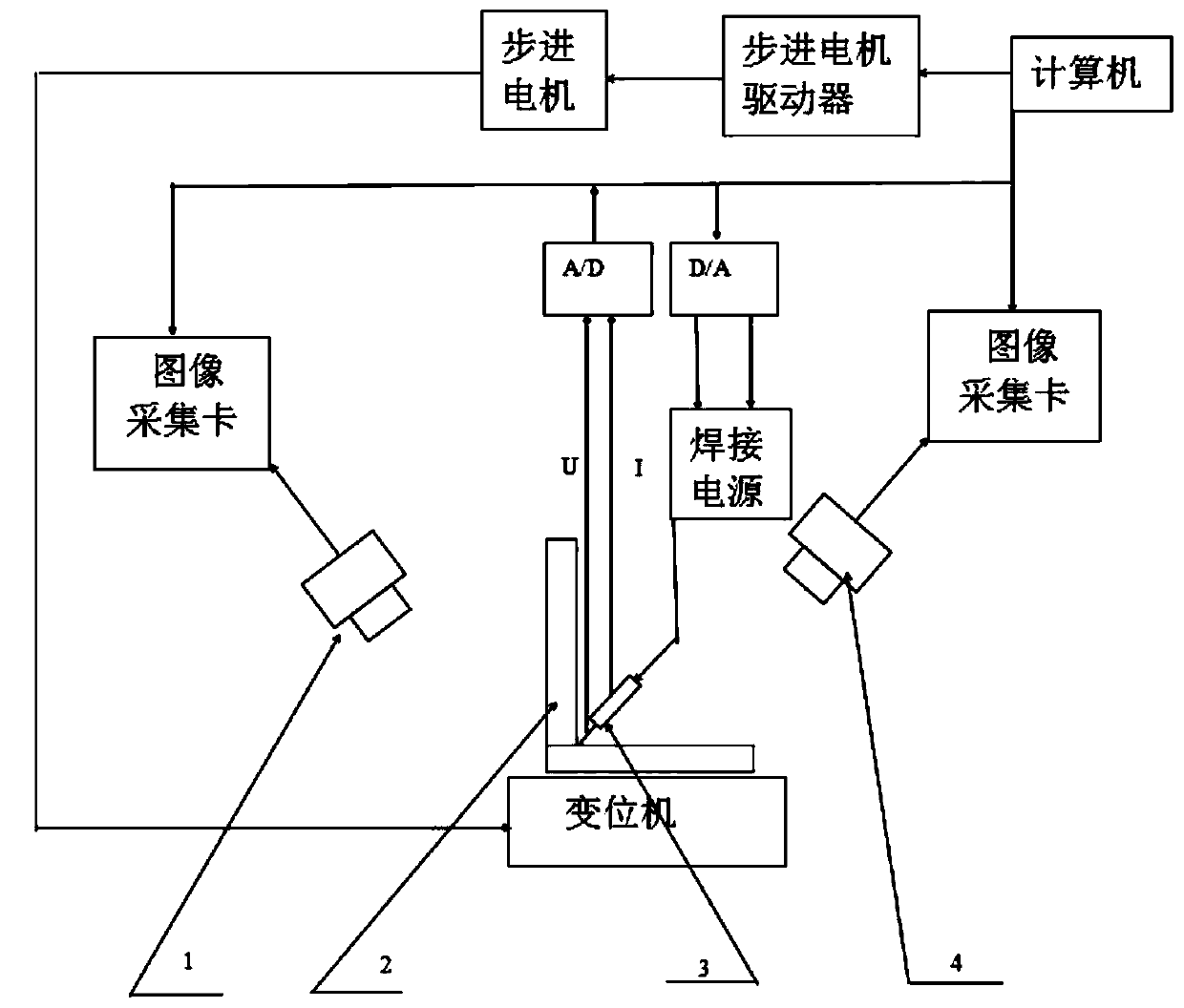

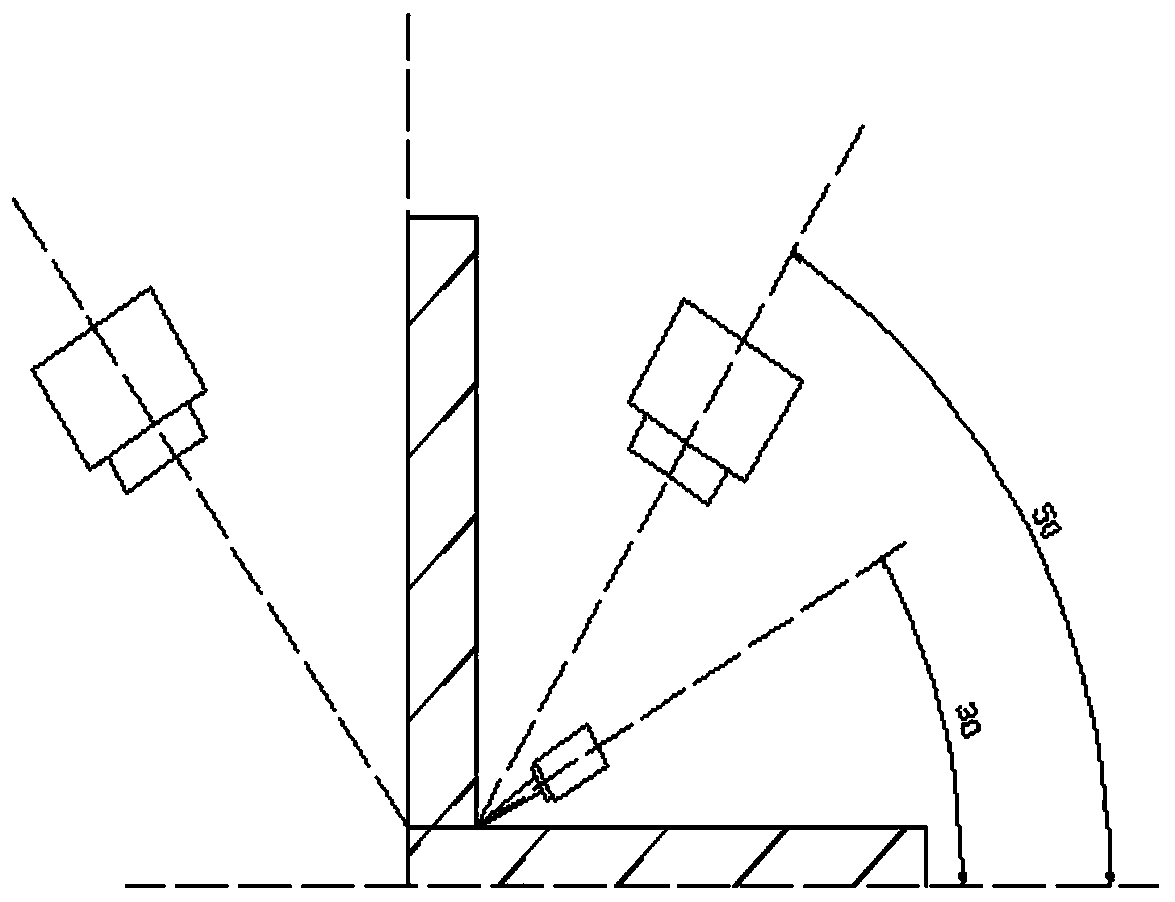

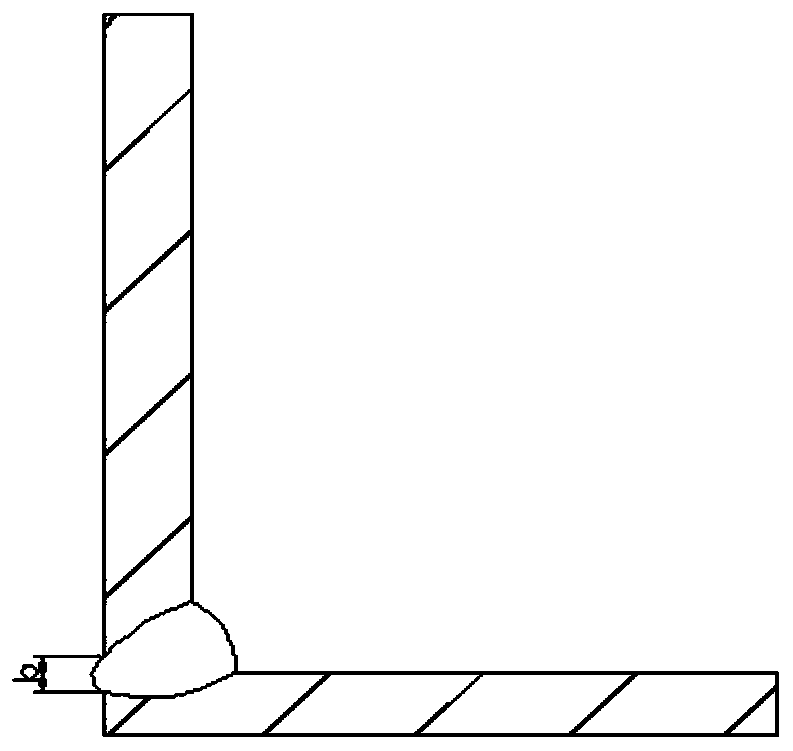

[0031] Such as figure 1 As shown, the system working principle diagram of the fillet joint penetration control method based on near-infrared binocular visual recognition of the present invention mainly includes: two near-infrared scanning CCD cameras 1 and 2 on the front and back, a welding torch, and a corner to be welded Pick up the workpiece. Among them, two near-infrared scanning CCD cameras on the front and back are fixed on both sides of the workpiece to be corner-jointed with fixtures according to the normal line of the lens end face and the normal line of the workpiece surface at an angle of 30°-45°, and the welding torch 2 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com