Equipment for cement laying on inclined wall of ditch

A cement and ditch technology, applied in cement mixing devices, water conservancy projects, artificial waterways, etc., can solve the problem of cement easily slipping to the bottom of the ditch, etc., and achieve the effect of preventing cement precipitation and cement leveling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

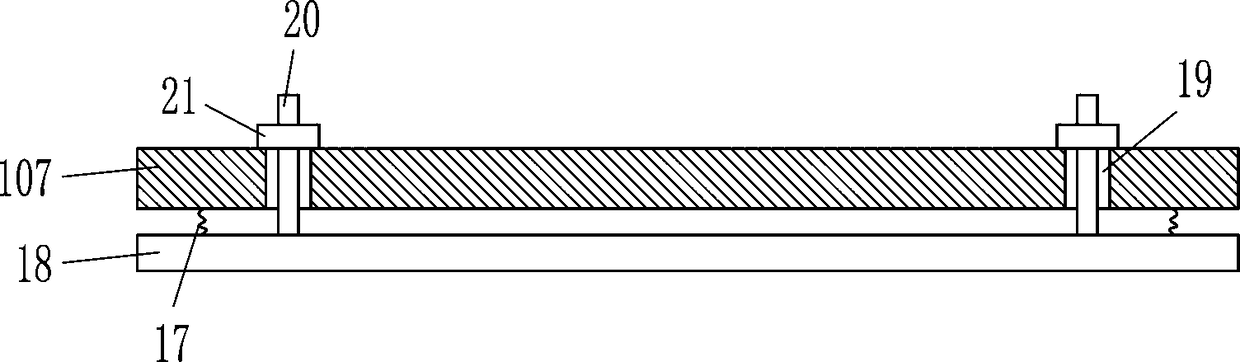

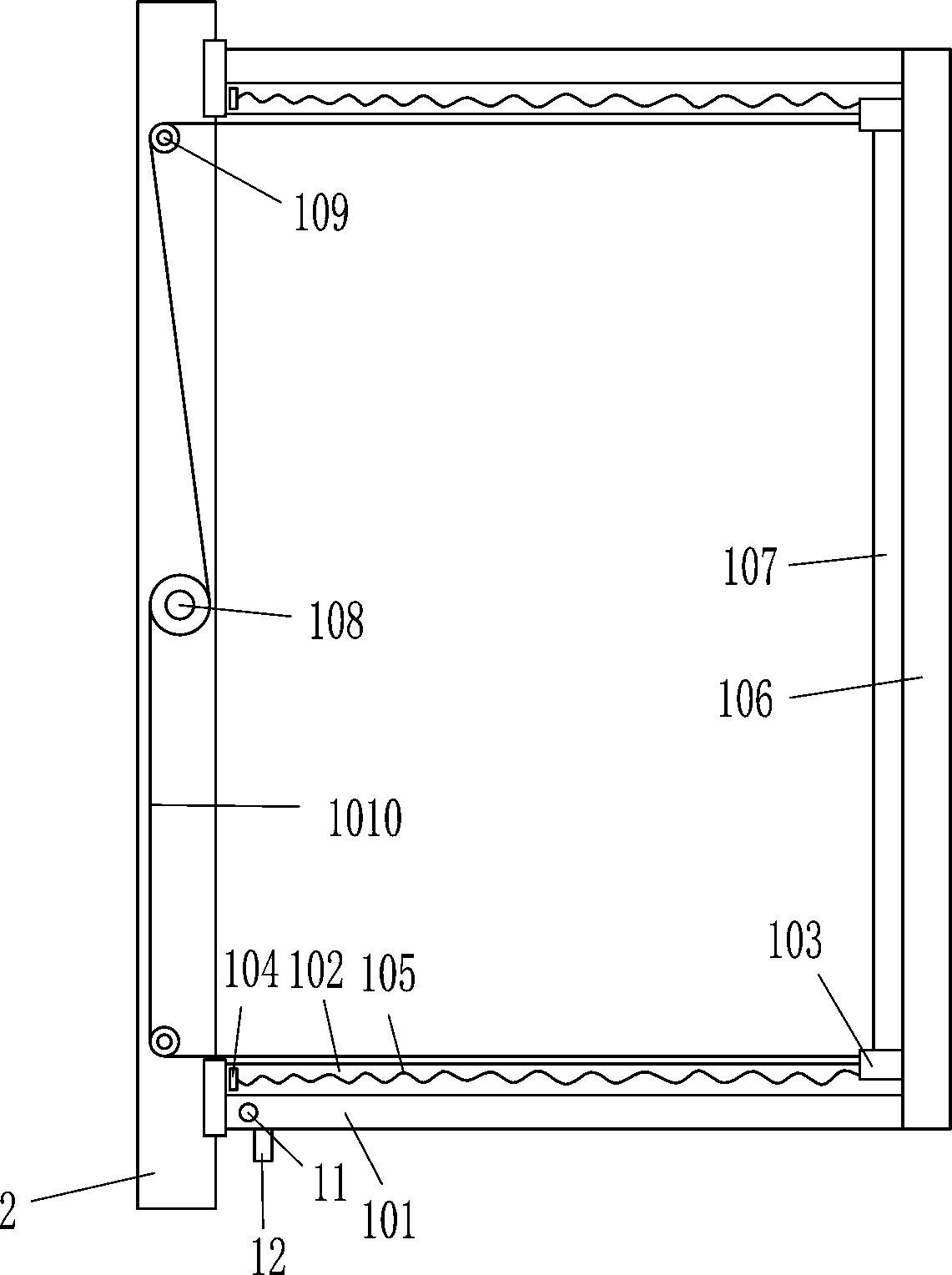

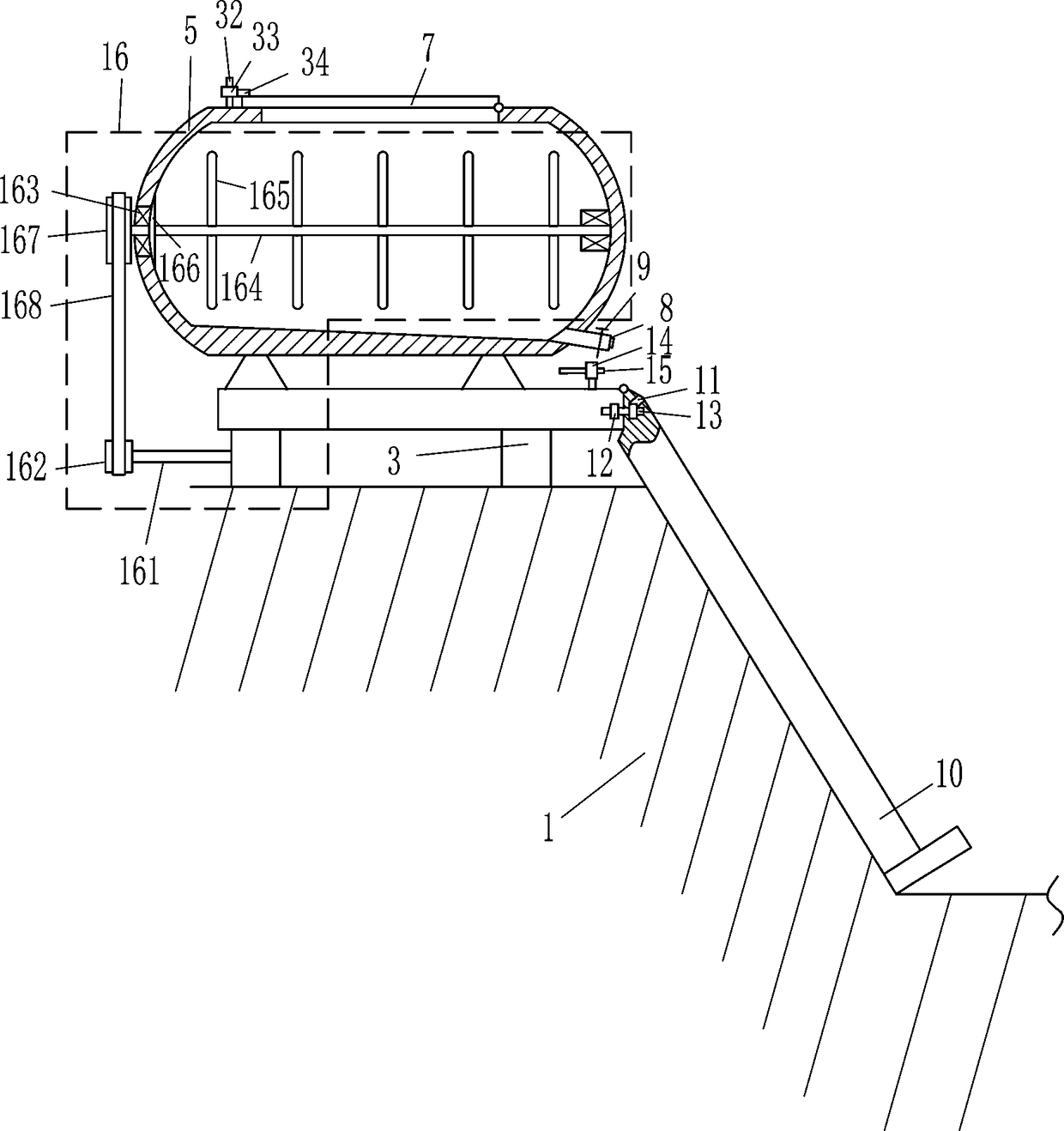

[0026] A kind of trench wall cement laying equipment, such as Figure 1-7As shown, it includes mounting plate 2, wheels 3, feet 4, cement box 5, cover plate 7, discharge pipe 8, large valve 9, cement paving device 10, first nut 12, first bolt 13, second Nut 14 and the second bolt 15, the top right of ditch body 1 is provided with mounting plate 2, the bottom of mounting plate 2 is equipped with wheels 3 on the front, rear, left, and right sides, and the upper side of mounting plate 2 is connected with feet 4, feet 4 The upper side is provided with a cement box 5, and the middle part of the upper side of the cement box 5 is provided with a feeding hole 6. The cement box 5 on the right side of the feeding hole 6 is hingedly connected with a cover plate 7, and the lower right side of the cement box 5 is embedded with a Discharge pipe 8, a large valve 9 is installed in the discharge pipe 8, the right end of the mounting plate 2 is hingedly connected with a cement paving device 10,...

Embodiment 2

[0028] A kind of trench wall cement laying equipment, such as Figure 1-7 As shown, it includes mounting plate 2, wheels 3, feet 4, cement box 5, cover plate 7, discharge pipe 8, large valve 9, cement paving device 10, first nut 12, first bolt 13, second Nut 14 and the second bolt 15, the top right of ditch body 1 is provided with mounting plate 2, the bottom of mounting plate 2 is equipped with wheels 3 on the front, rear, left, and right sides, and the upper side of mounting plate 2 is connected with feet 4, feet 4 The upper side is provided with a cement box 5, and the middle part of the upper side of the cement box 5 is provided with a feeding hole 6. The cement box 5 on the right side of the feeding hole 6 is hingedly connected with a cover plate 7, and the lower right side of the cement box 5 is embedded with a Discharge pipe 8, a large valve 9 is installed in the discharge pipe 8, the right end of the mounting plate 2 is hingedly connected with a cement paving device 10...

Embodiment 3

[0031] A kind of trench wall cement laying equipment, such as Figure 1-7 As shown, it includes mounting plate 2, wheels 3, feet 4, cement box 5, cover plate 7, discharge pipe 8, large valve 9, cement paving device 10, first nut 12, first bolt 13, second Nut 14 and the second bolt 15, the top right of ditch body 1 is provided with mounting plate 2, the bottom of mounting plate 2 is equipped with wheels 3 on the front, rear, left, and right sides, and the upper side of mounting plate 2 is connected with feet 4, feet 4 The upper side is provided with a cement box 5, and the middle part of the upper side of the cement box 5 is provided with a feeding hole 6. The cement box 5 on the right side of the feeding hole 6 is hingedly connected with a cover plate 7, and the lower right side of the cement box 5 is embedded with a Discharge pipe 8, a large valve 9 is installed in the discharge pipe 8, the right end of the mounting plate 2 is hingedly connected with a cement paving device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com