Lightweight wire cutting machine

A wire cutting machine, lightweight technology, applied in work accessories, fine work devices, stone processing equipment, etc., can solve problems such as rack weight, achieve light rack structure, easy filling and removal, and prevent instability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

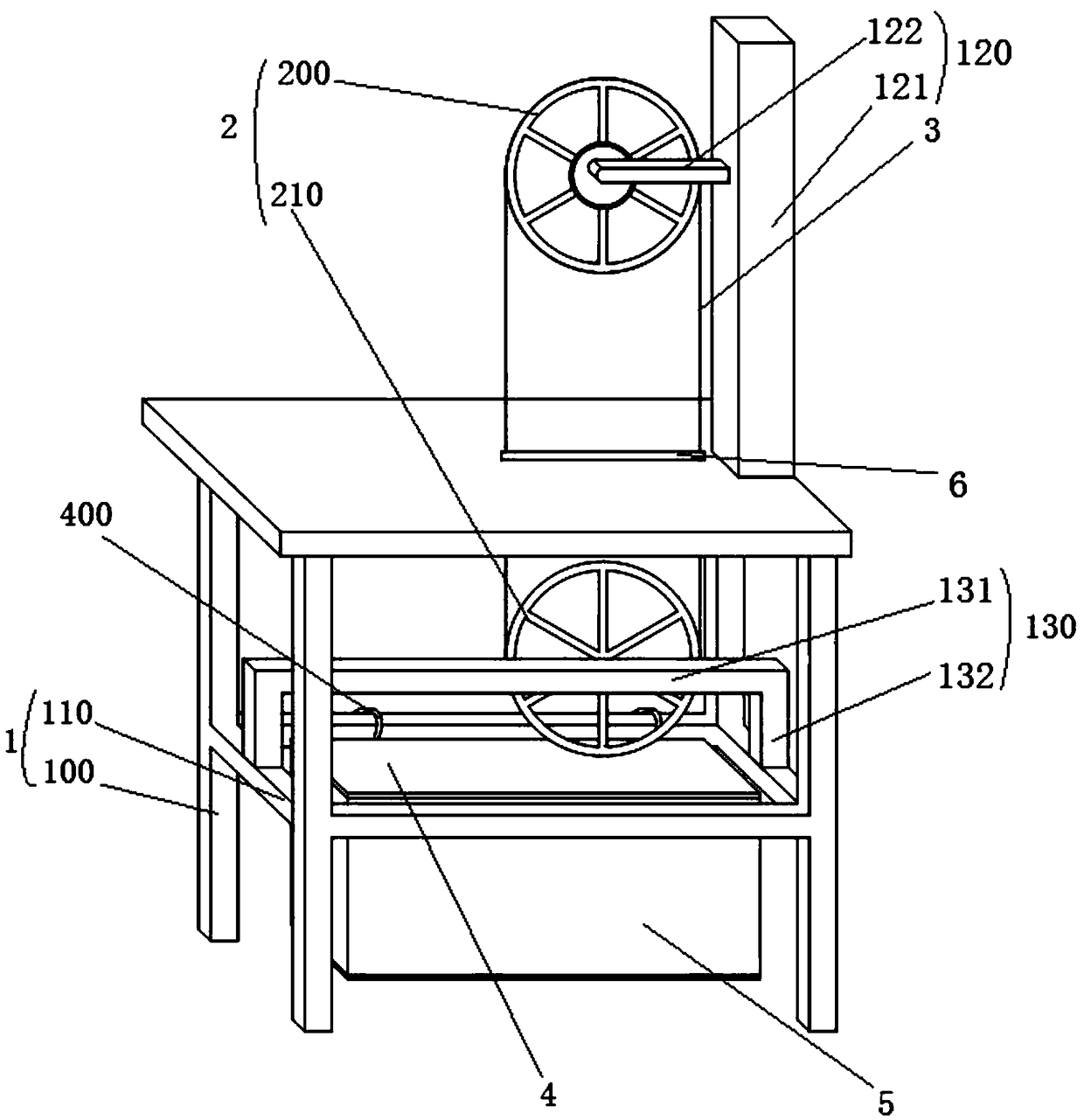

[0023] The light-weight wire cutting machine in this embodiment includes a frame 1 and a guide wheel 2 installed on the frame. There are two guide wheels, and the two guide wheels are respectively a driving wheel 200 and a driven wheel 210 . The driving wheel and the driven wheel are wound with a diamond wire saw 3 . The diamond wire saw 3 is an annular diamond wire saw. Frame 1 is assembled from lightweight materials. Lightweight material is aluminum profile. The frame includes a support frame and a working platform fixed on the top of the support frame. The driving wheel is located above the working platform, and the driven wheel is located below the working platform. The working platform is provided with a through hole 6 for the circular diamond wire saw to pass through. One through hole 6 is provided, and the through hole 6 is an elongated through hole for the two wires of the ring diamond wire saw to pass through. The upper part of the frame 1 is provided with an upp...

Embodiment 2

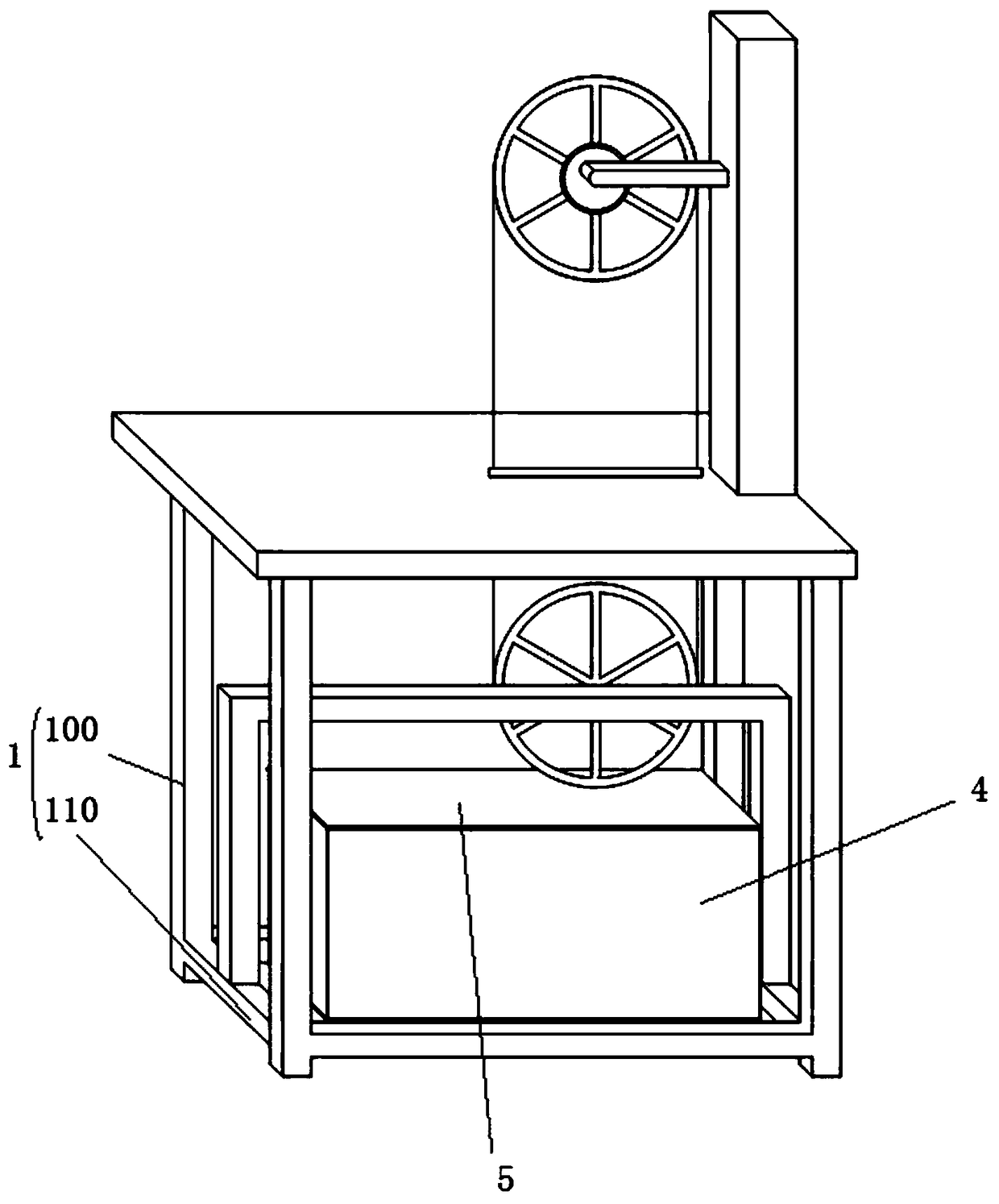

[0027] The general structure of the lightweight wire cutting machine described in this embodiment is consistent with that of Embodiment 1, but it is different from Embodiment 1 in that there are two through holes, and the two through holes are respectively set on the two wires of the diamond wire saw. place.

Embodiment 3

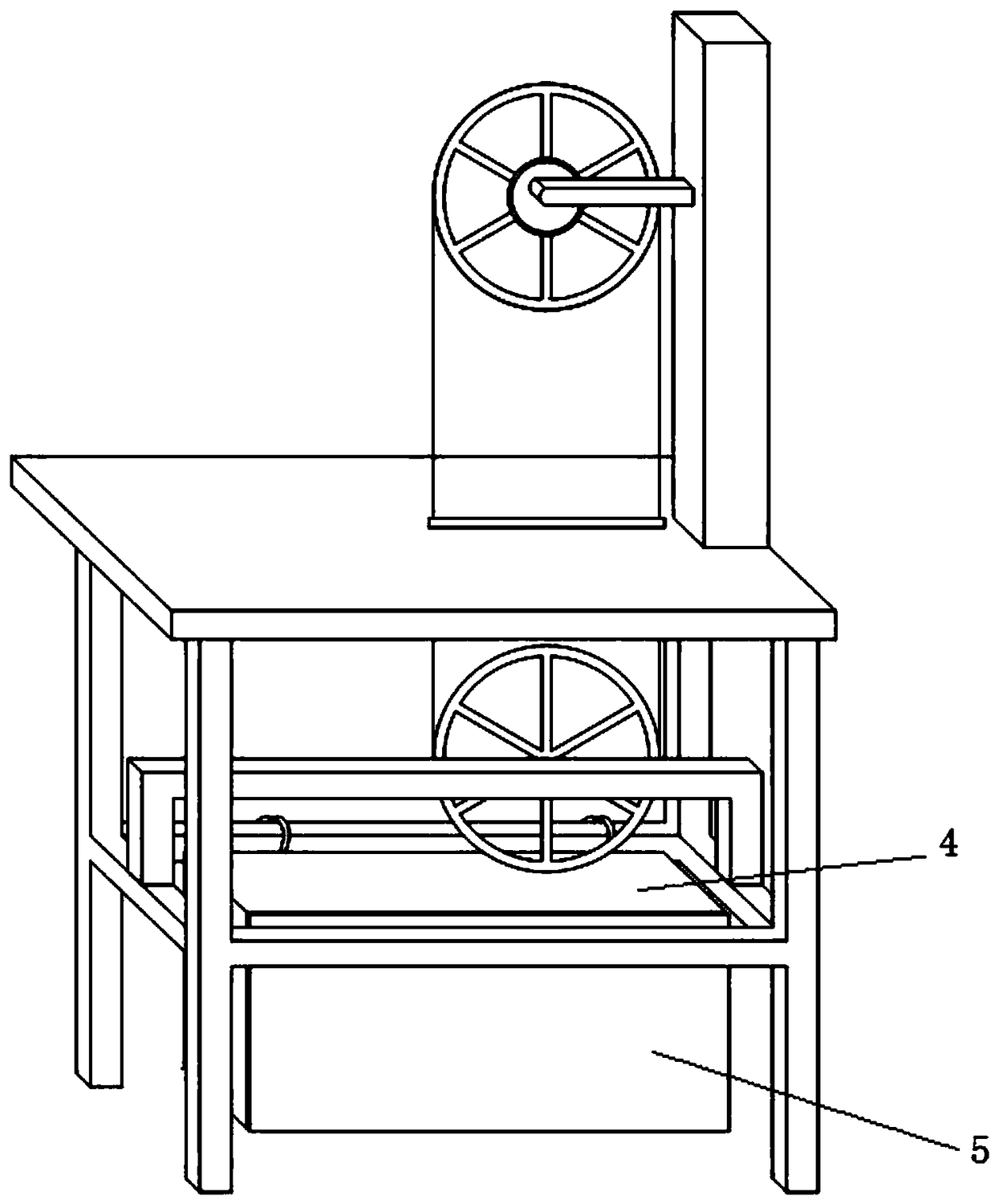

[0029] The general structure of the lightweight wire cutting machine described in this embodiment is consistent with that of Embodiment 1, but the difference from Embodiment 1 is that the frame is provided with two counterweight chambers for accommodating counterweights.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com