Intra-mold glue spraying method

A technology of spraying glue and mold base, applied in the field of mold processing, can solve the problems of high temperature of the material pipe, spraying glue when the injection molding machine opens the mold, and wet raw materials, etc., and achieves the effect of uniform spraying of glue, reduction of assembly lines, and reduction of production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

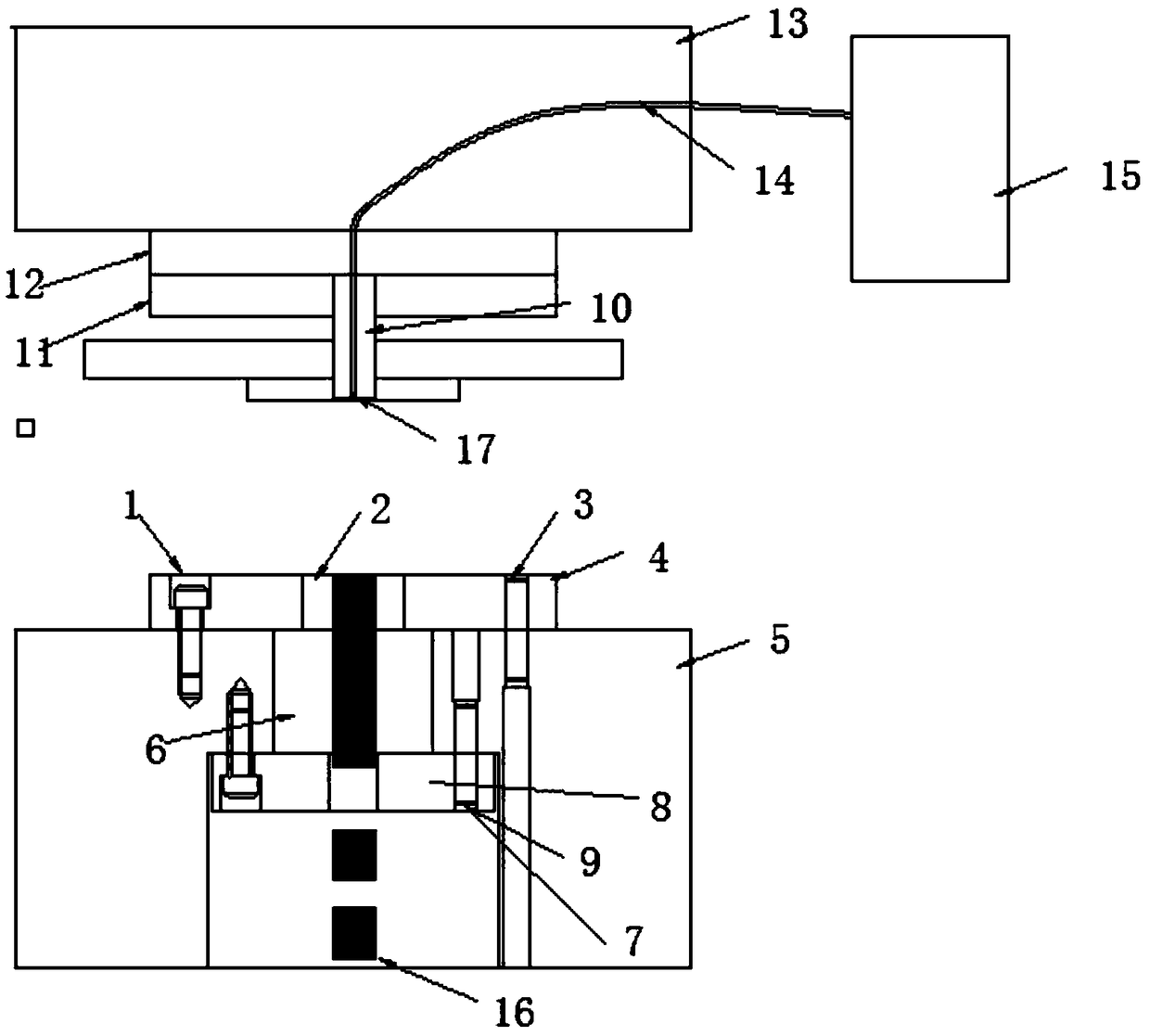

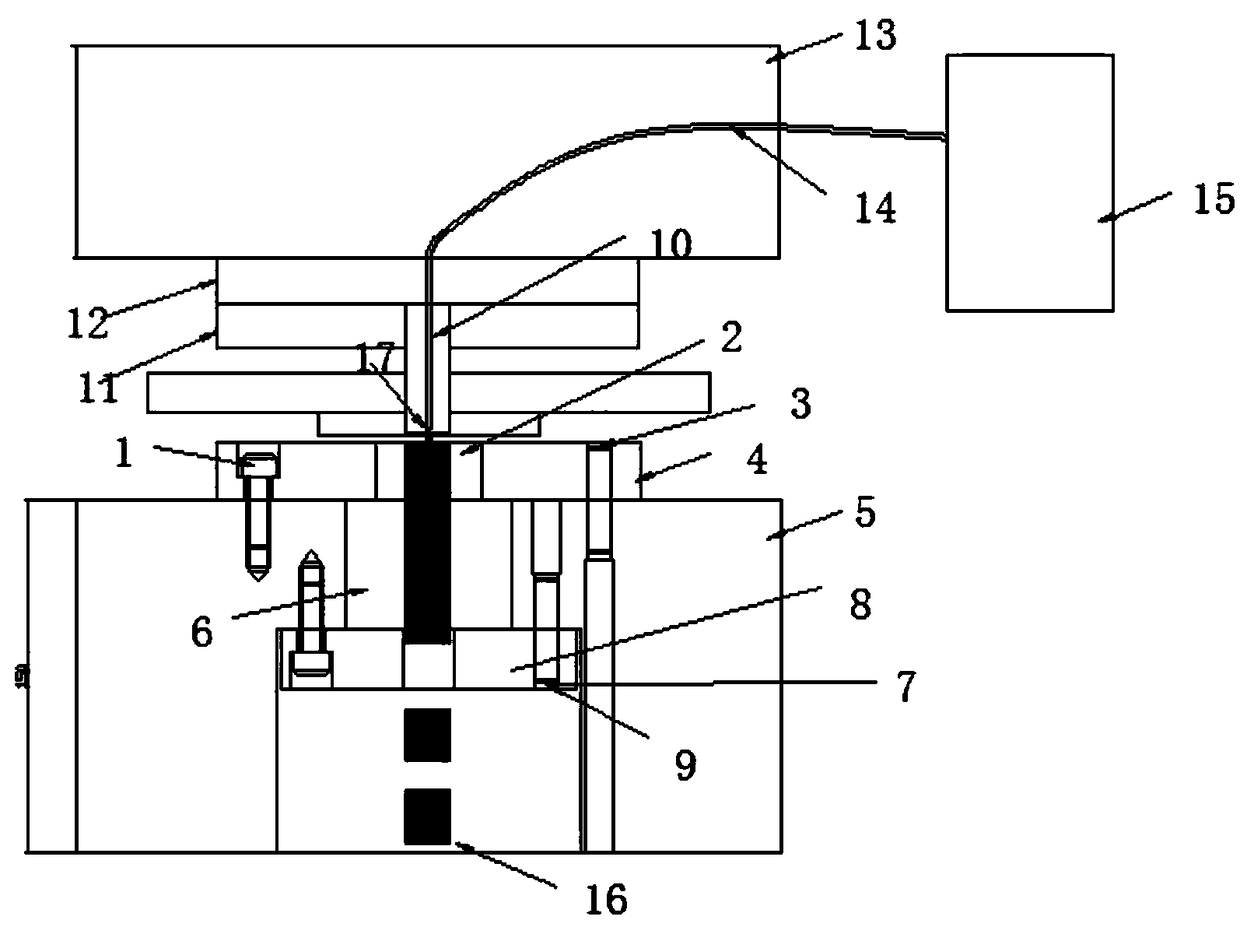

[0014] combined with figure 1 , 2 , the present embodiment provides a method of spraying glue in the mold, wherein the mold includes a screw one 1, a blanking die 2, a pin one 3, a die fixing plate 4, a lower mold frame 5, a locking ring 6, two screws 7. Locking ring cover plate 8, pin 2 9, blanking punch 10, punch fixing plate 11, punch backing plate 12, upper mold frame 13, glue spray pipe 14, glue controller 15 and processed products 16, drop The material die 2 is positioned with the lower die frame 5 through the pin 1, and locked with the lower die frame 5 through the screw 1. The blanking die 2 adopts a bilateral interference of 0.02MM to cooperate with the die fixing plate 4, and the locking ring 6 passes through Interference 0.01MM cooperates with the lower mold frame 5, the locking ring cover plate 8 is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com