Composite material prepreg tape laying machine

A composite material and prepreg tape technology, applied in the field of composite material prepreg tape laying machines, can solve the problems of inability to realize the arrangement and layout of prepreg tapes, and achieve the effects of good bonding tightness, reduced scrap rate, and high bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

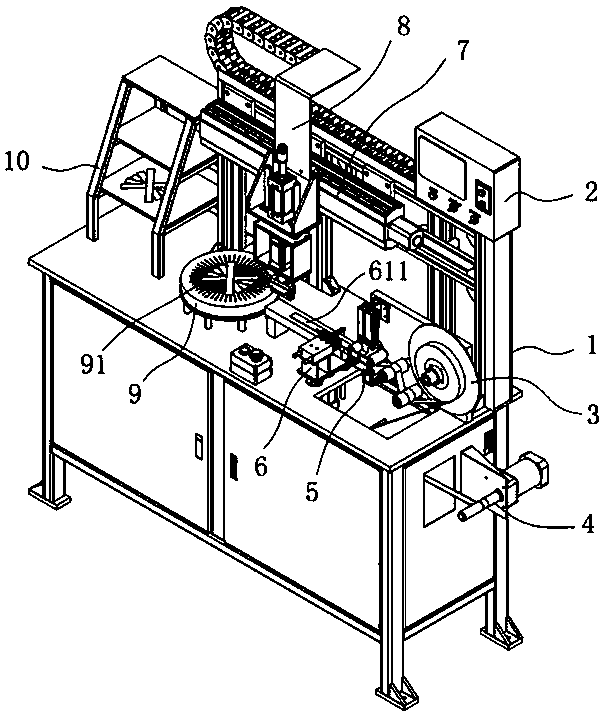

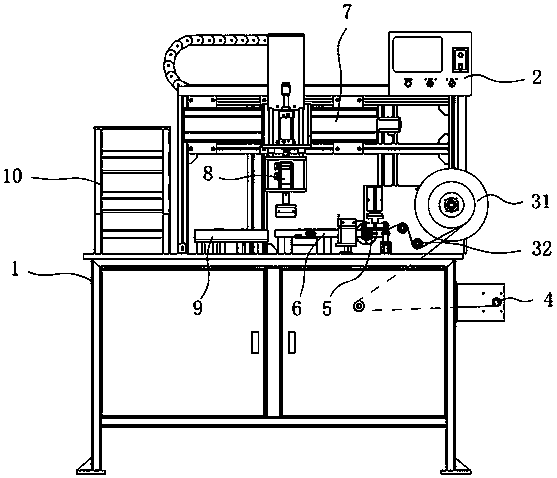

[0026] Such as figure 2 As shown, the invention discloses a composite material prepreg tape laying machine, comprising a frame 1, a control box 2, a prepreg tape unwinding device 3 controlled by the control box 2 arranged on the frame 1, a film winding Device 4, pressing device 5, cutting device 6, slide module 7, reclaiming device 8 and suction cup seat 9. The frame 1 may be provided with a product storage ladder frame 10 for storing finished products.

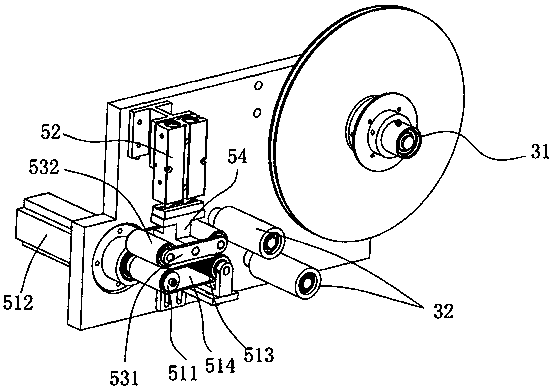

[0027] combine image 3 As shown, the prepreg tape unwinding device 3 is used for winding the prepreg tape. The prepreg tape unwinding device 3 includes an unwinding reel 31 and two guide wheels 32 arranged on one side of the unwinding reel 31 . The guide wheels 32 are arranged up and down, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com