An automobile tire safety device and its parameter setting method

A technology for safety devices and automobile tires, which is applied to tire parts, vehicle parts, transportation and packaging, etc., can solve the problems of a small range of applicable models, and achieve the effects of simple design methods, reduced traffic accidents, and easy repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

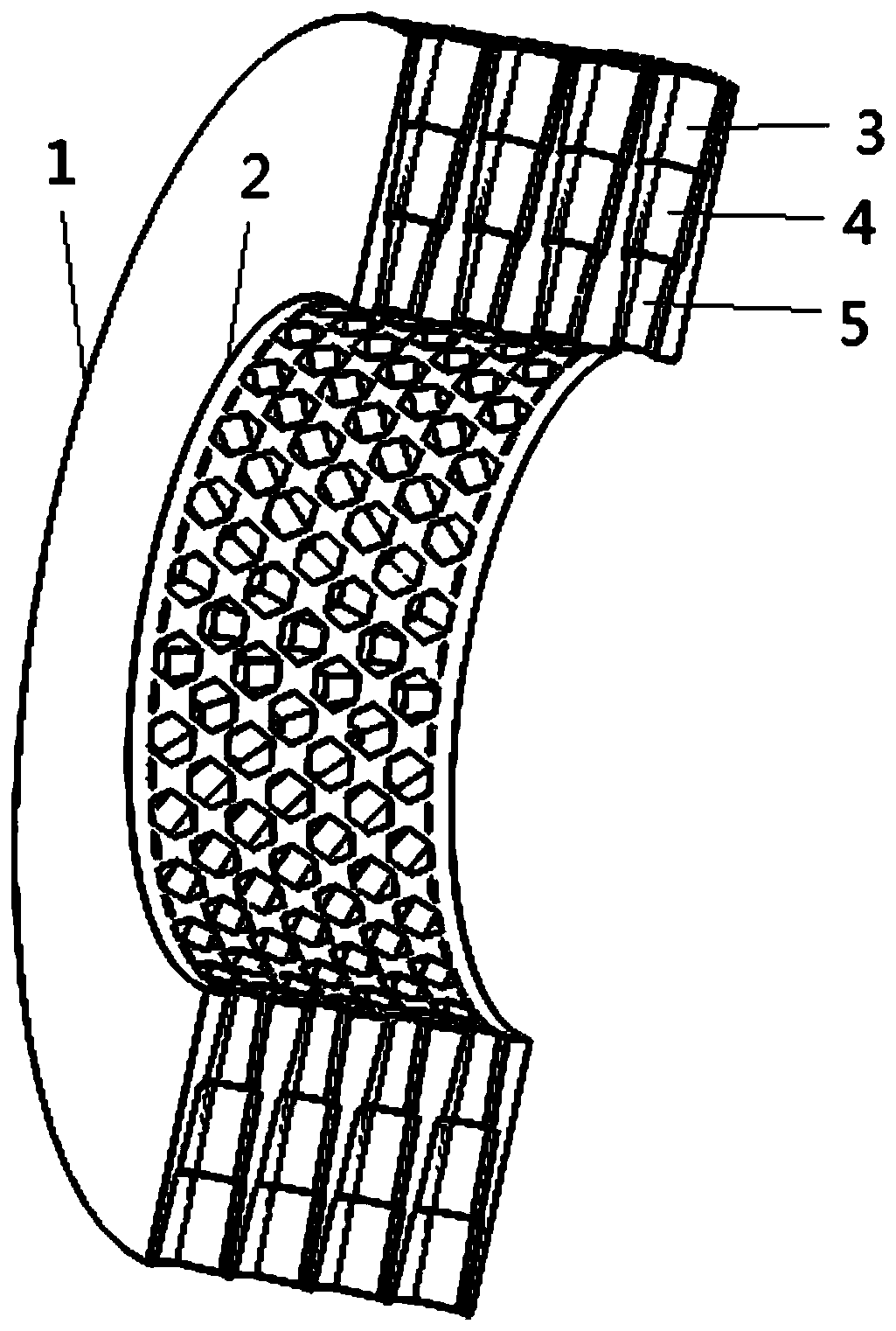

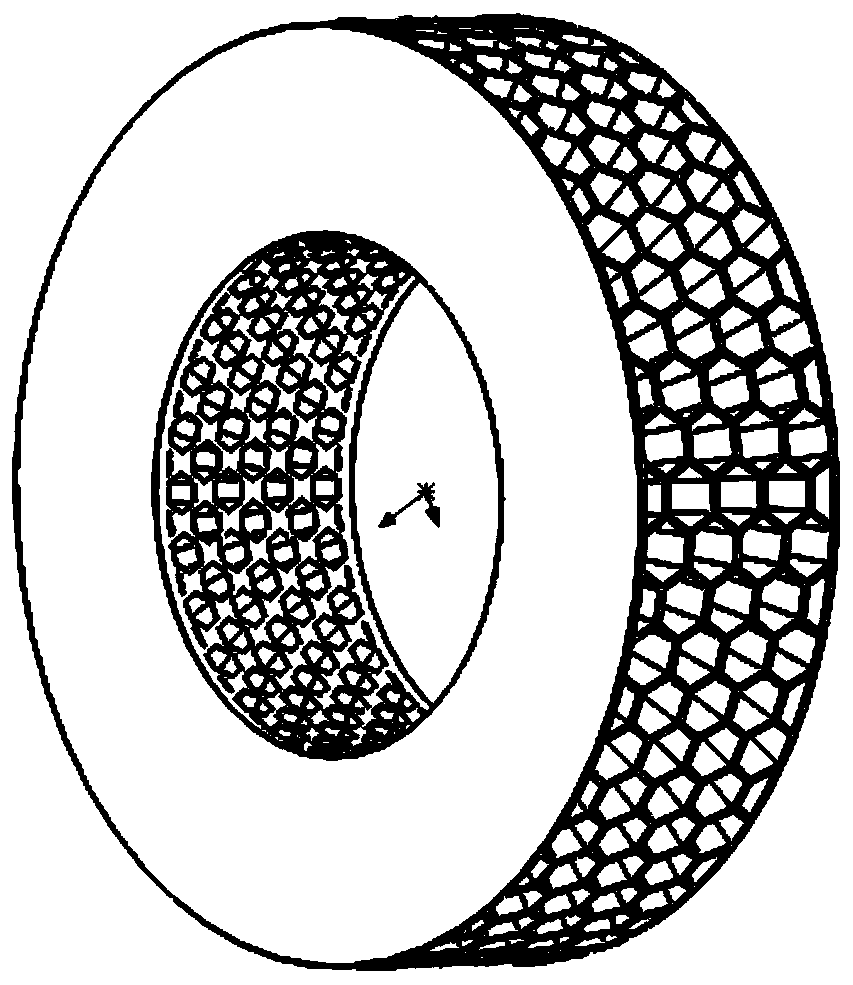

[0042] Specific implementation mode one: combine Figure 1 to Figure 3 To illustrate this embodiment, an automobile tire safety device described in this embodiment includes an outer layer, a middle layer and an inner layer arranged concentrically in sequence from outside to inside, wherein,

[0043] The outer diameter of the outer layer is equal to the inner diameter of the tire, and the inner diameter of the inner layer is equal to the nominal diameter of the rim;

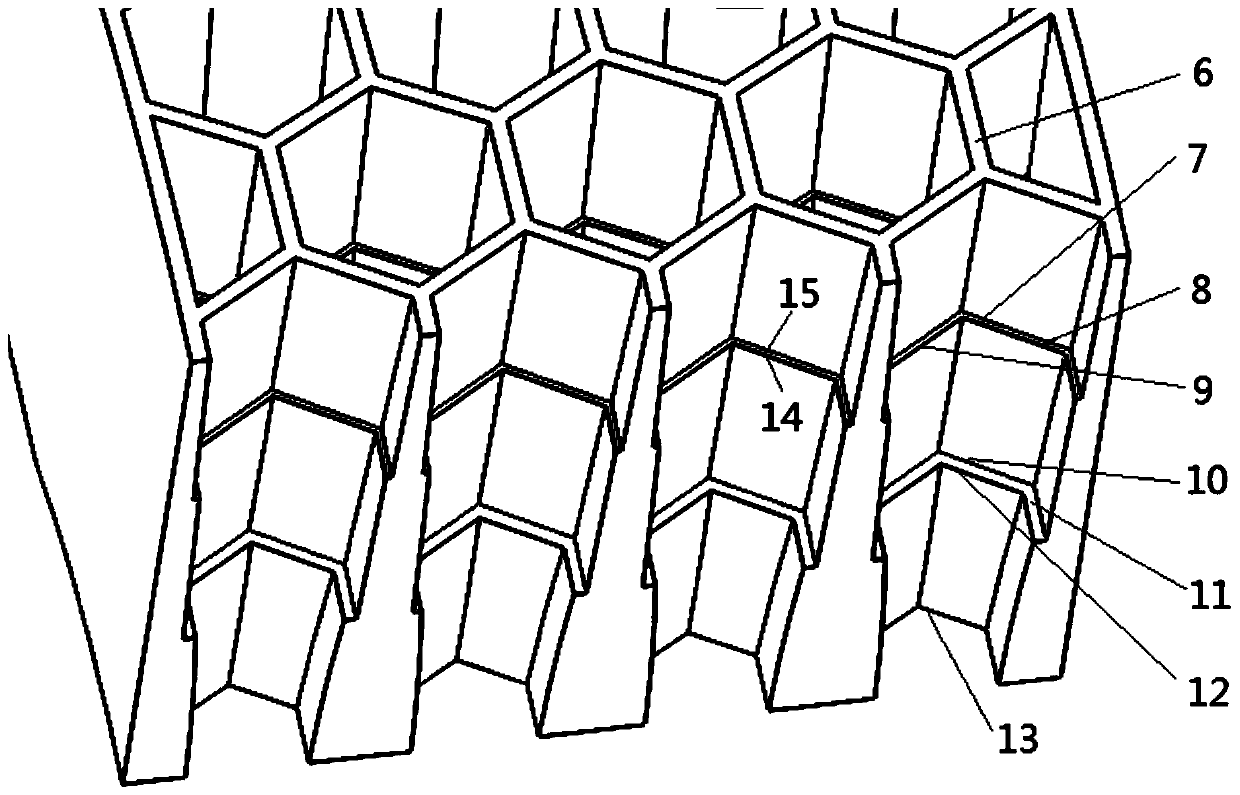

[0044] The outer layer, middle layer and inner layer are all provided with transparent hexagonal holes along the radial direction of the tire, and the hexagonal holes in each layer are arranged in a honeycomb shape, and the hexagonal holes on the outer layer, middle layer and inner layer One-to-one correspondence of polygonal holes, the corresponding three hexagonal holes are connected, and the side length of the hexagonal hole on the outer surface of the outer layer > the side length of the hexagonal hole on the ...

specific Embodiment approach 2

[0069] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, this embodiment is a parameter setting method of an automobile tire safety device described in Embodiment 1, including the following steps:

[0070] Step 1. Divide the car tire safety device into three layers from the outside to the inside, namely the outer layer, the middle layer and the inner layer, wherein the outer diameter of the outer layer is equal to the inner diameter of the tire, and the inner diameter of the inner layer is equal to the nominal diameter of the rim;

[0071] Step 2, setting the structural parameters of the outer surface of the outer layer, specifically including the following steps:

[0072] Step 21, setting the maximum number of hexagonal holes on the outer surface of the outer layer along the axial direction of the tire: n=2 to 10;

[0073] Step 22. Set the distance between two adjacent hexagonal holes on the outer surface of the outer layer along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com