Spring energy storing brake device of emergency automated automobile

A technology of energy storage braking and automobile spring, applied in the direction of brake transmission, foot start device, brake, etc., can solve the problem of soft brake delay, improper increase of front air chamber volume, insufficient installation space of solenoid valve and surrounding Parts interfere with each other and other problems, so as to achieve the effect of no delay in braking and no increase in braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

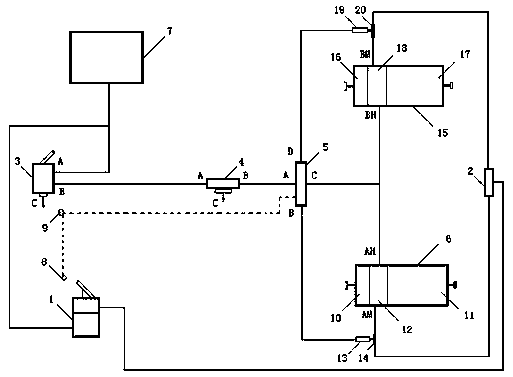

[0014] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the spring energy storage braking device for emergency automatic vehicles proposed according to the present invention will be described in detail as follows.

[0015] see figure 1 , the spring energy storage braking device for emergency automated automobiles of the present invention includes a brake valve 1, a quick release valve 2, a parking control valve 3, a relay valve 4, an emergency solenoid valve 5, a spring energy storage brake chamber A6, Air storage cylinder 7, foot control power switch 8, manual power switch 9, spring energy storage brake chamber B15, one-way valve A13, three-way A14, one-way valve B19, three-way B20, of which: spring energy storage brake The air chamber A6 is composed of the front air chamber A10, the rear air chamber A11, and the intermediate body A12. The spring energy storage brake air chamber B15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com