Air conditioning structure for rail traffic and rail traffic

A rail transit and air conditioning technology, applied in the field of rail transit, can solve the problems of inability to guarantee the heat exchange effect, unsatisfactory heat exchange effect, limited head space, etc., and achieve the effects of smooth air outlet, space saving, and small air supply resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

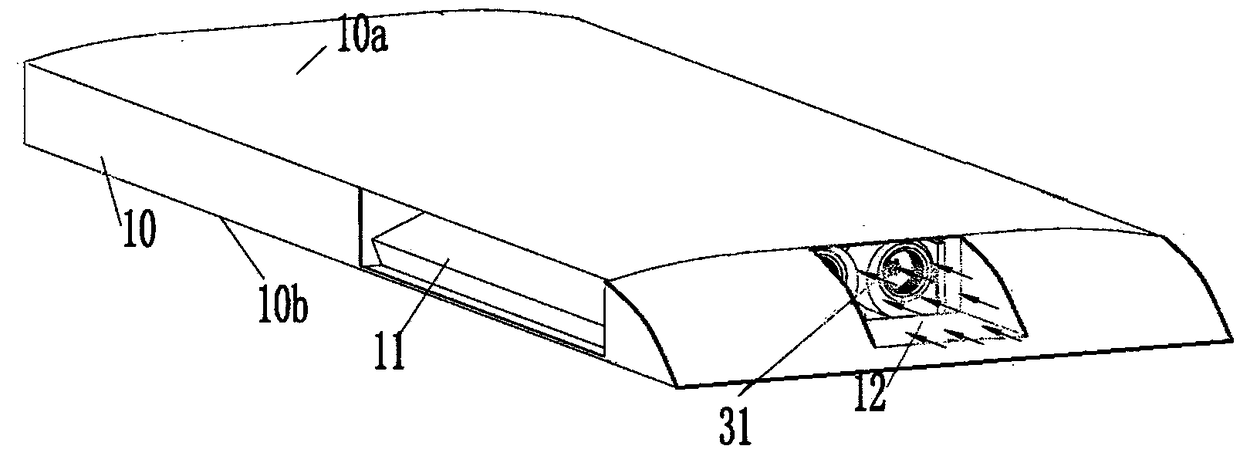

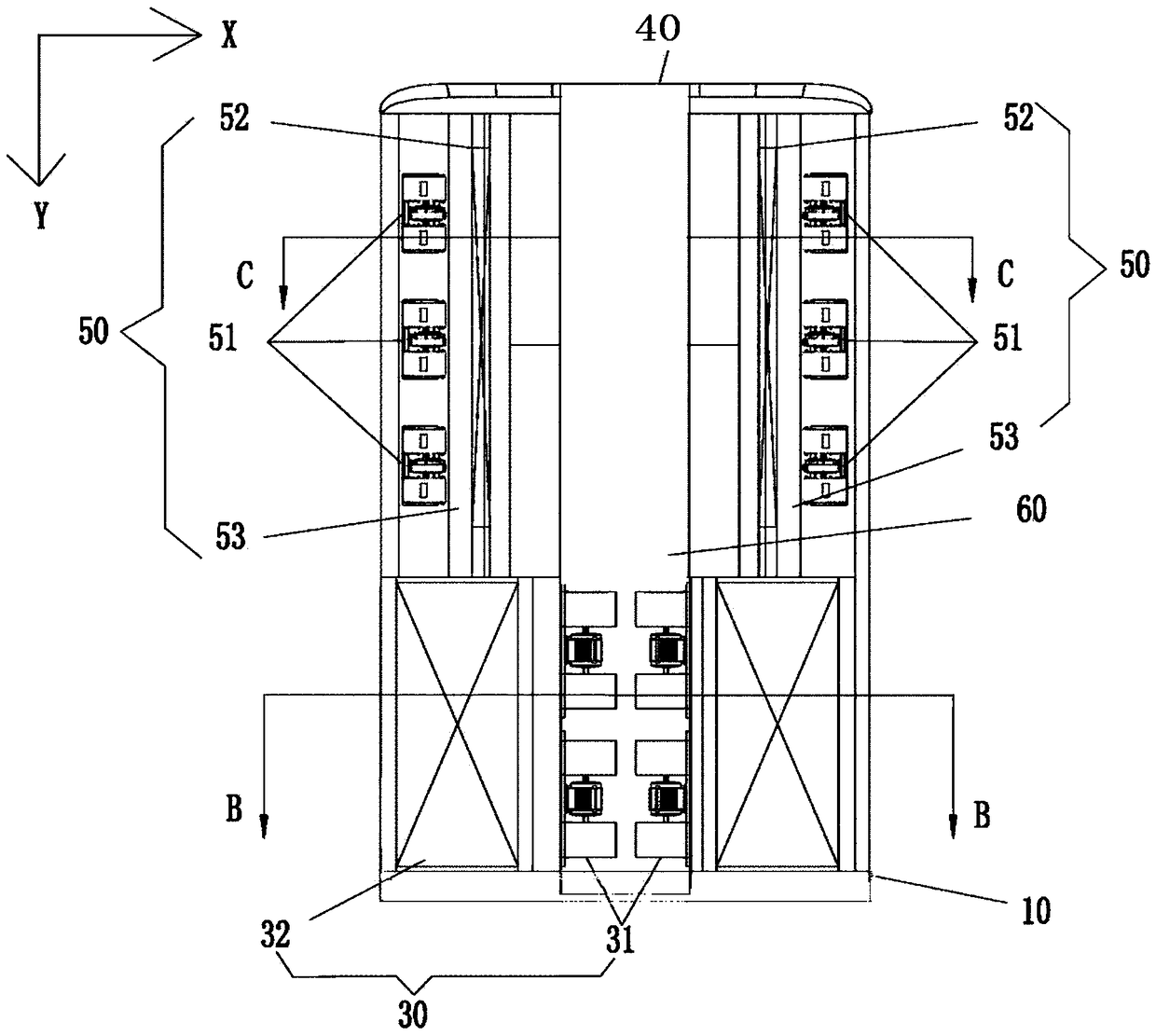

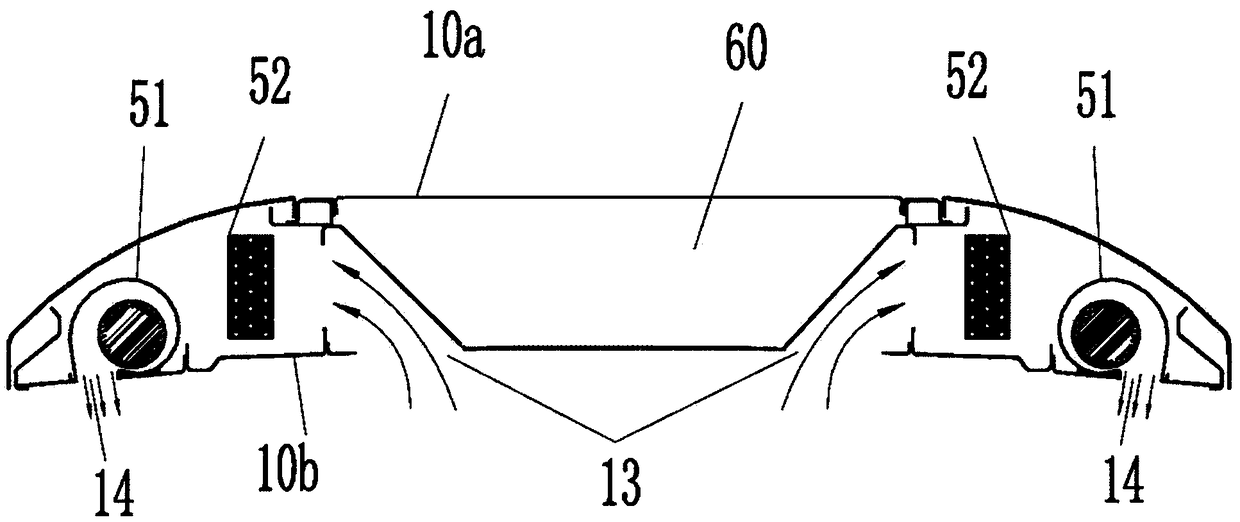

[0036] Such as Figure 1-5 As shown, the application provides a rail transit air-conditioning structure, including: an air-conditioning body 10 and a first heat exchanger assembly 30 and a second heat exchanger assembly 50 disposed in the air-conditioning body 10; the air-conditioning body 10 Including a fairing 10a and a bottom plate 10b; the front end of the fairing 10a is provided with an air inlet 12, the rear end of the fairing 10a is provided with a vent 40, and the side of the fairing 10a is provided with a first air outlet 11, the The bottom plate 10b is provided with an air return port 13 and a second air outlet 14; in the longitudinal direction of the rail transit car 1, the second heat exchanger assembly 50 and the first heat exchanger assembly 30 are arranged front and back; A heat exchanger assembly 30 includes a first heat exchange air passage, and the air inlet 12 communicates with the first air outlet 11 through the first heat exchange air passage; the second h...

Embodiment 2

[0040] Such as Figure 1-5 As shown, the difference between this embodiment and embodiment 1 only lies in:

[0041] The outer surface of the fairing 10a is streamlined. Several triangular reinforcing plates are arranged between the fairing 10a and the bottom plate 10b. The second air outlet 14 communicates with the indoor air.

[0042]The first heat exchanger assembly 30 is a condenser assembly, the first heat exchanger 32 is a condenser, and the first heat exchange air channel is a condensation air channel; the second heat exchanger assembly 50 is an evaporator assembly, and the second heat exchanger 52 is an evaporator, and the second heat exchange air duct 53 is an evaporation air duct. The first heat exchanger assembly 30 includes two first heat exchange air passages, the first heat exchange air passages are provided with a first fan 31 and a first heat exchanger 32, and the first fan 31 Relative to the first heat exchanger 32 , it is arranged closer to the air inlet 4...

Embodiment 3

[0045] Such as Figure 1-5 As shown, the difference between this embodiment and Embodiment 2 is only that: the first heat exchanger assembly 30 is an evaporator assembly, the first heat exchanger 32 is an evaporator, and the first heat exchange air duct is an evaporation air duct; The heat exchanger assembly 50 is a condenser assembly, the second heat exchanger 52 is a condenser, and the second heat exchange air channel 53 is a condensation air channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com