Battery packaging line

A packaging line and battery technology, applied in the field of packaging, can solve the problems of low artificial packaging accuracy, high operation and maintenance costs, and a large number of packaging equipment, and achieve automatic flow operation, small footprint, and high degree of automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

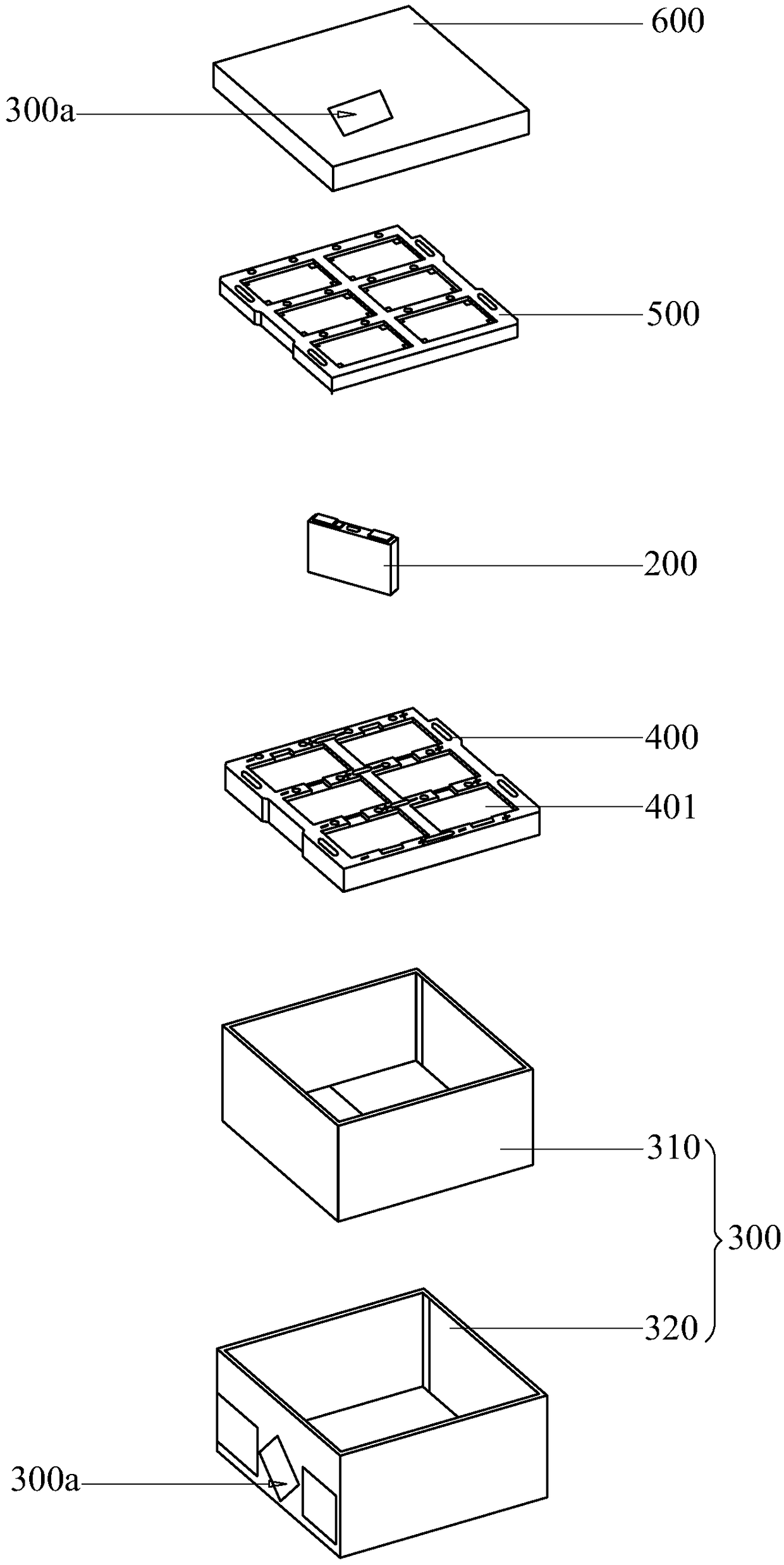

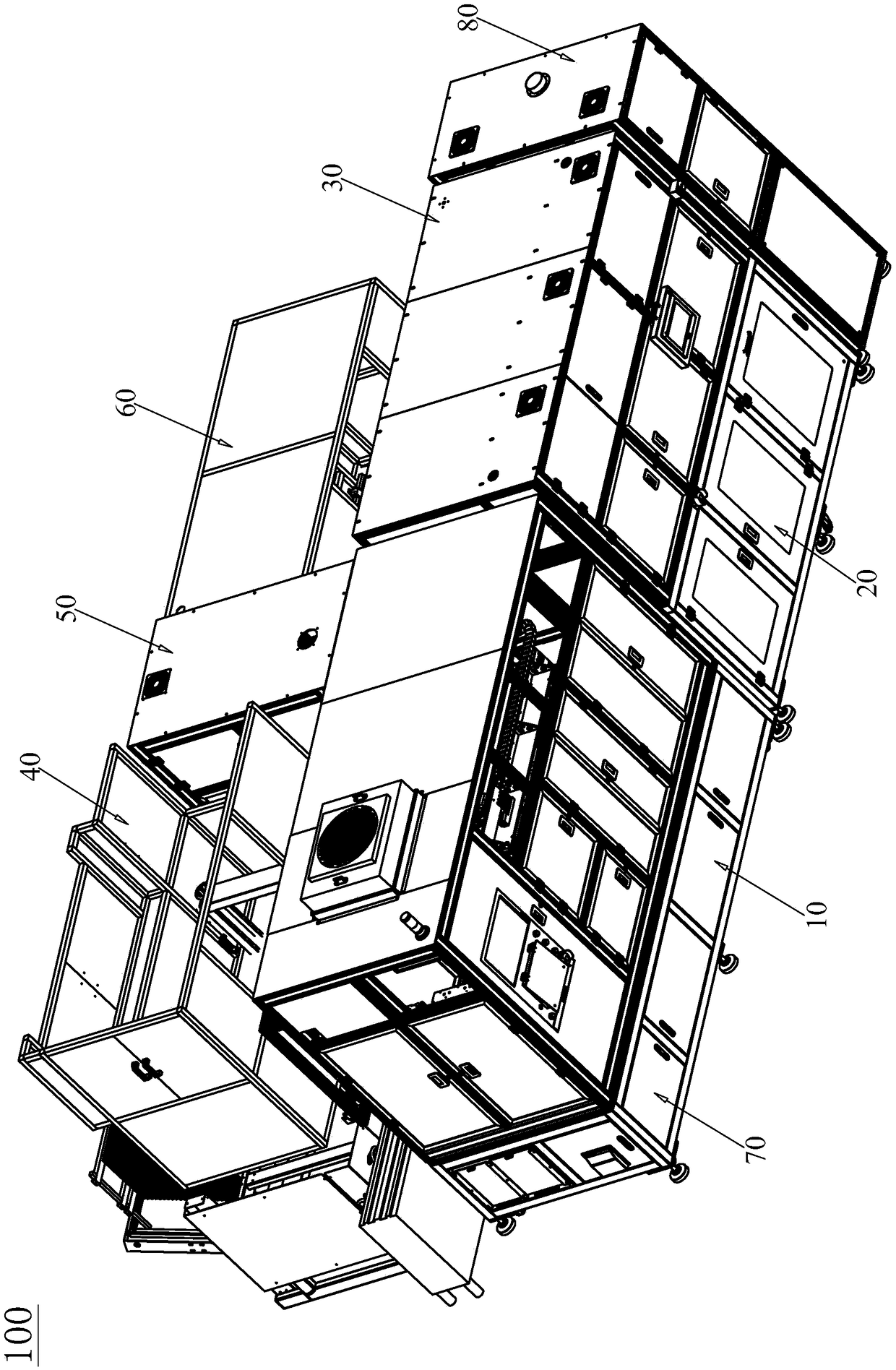

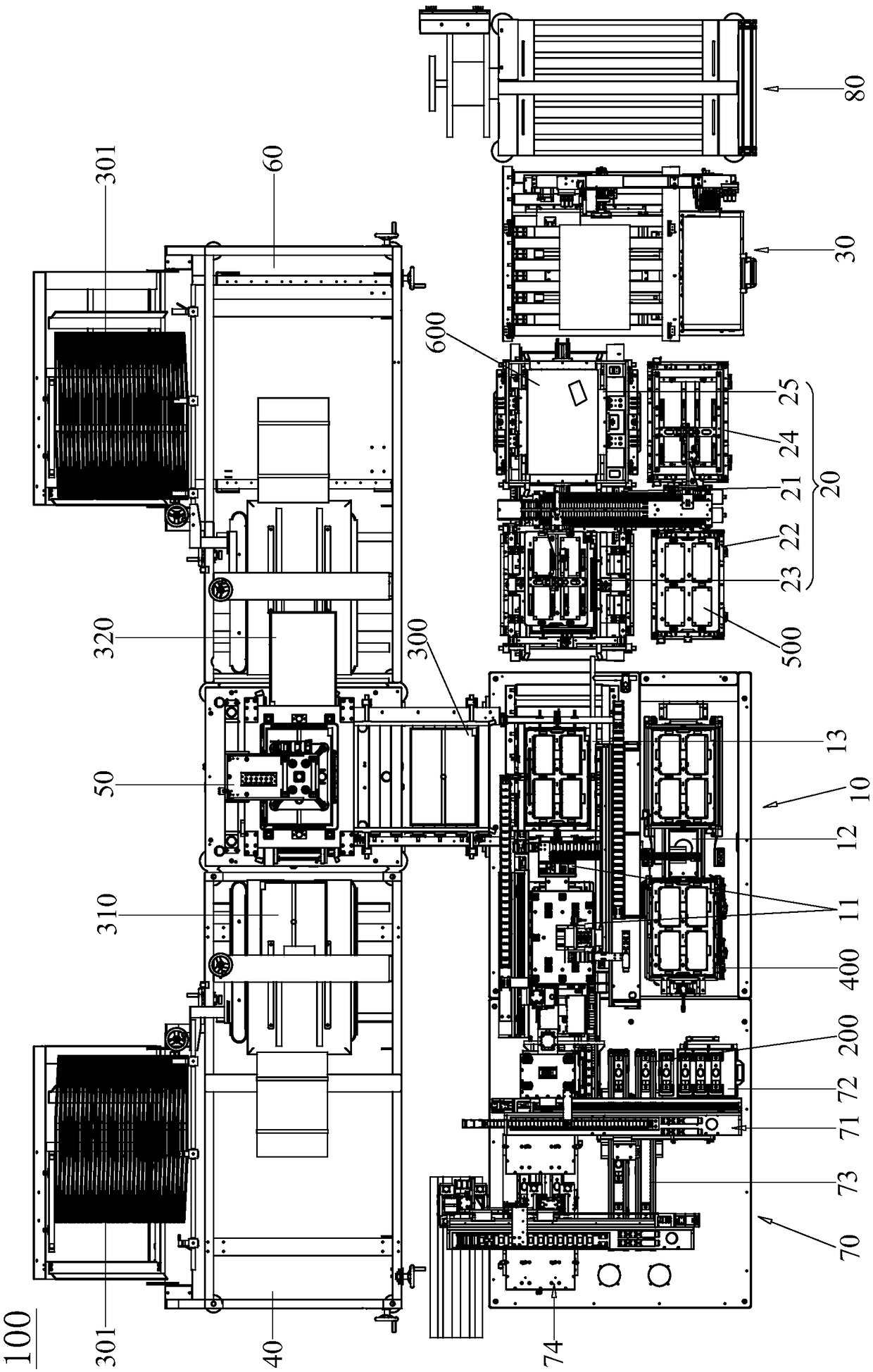

[0036] see figure 1, the present invention discloses a battery packaging line 100 for packaging batteries 200 in packaging boxes 300. In order to better protect the batteries, the battery packaging line 100 of the present invention firstly fixes the batteries 200 on plastic trays at intervals 400, then put the plastic tray 400 with the battery 200 into the packaging box 300 which is formed by the inner box 310 and the outer box 320, and then fasten the plastic cover 500 on the plastic tray 400 inside the packaging box 300 To package the battery 200 located between the two, and then fasten the outer cover 600 to the opening of the packaging box 300 , so that the battery 200 is safely and effectively packaged in the packaging box 300 . Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com