Preparation method of high-permeability asphalt recycling agent

An asphalt regenerant and high permeability technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor bonding effect, poor penetration ability of asphalt regenerant, poor strength of recycled asphalt, etc. The effect of compaction, improvement of asphalt regeneration capacity, and enhanced penetration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

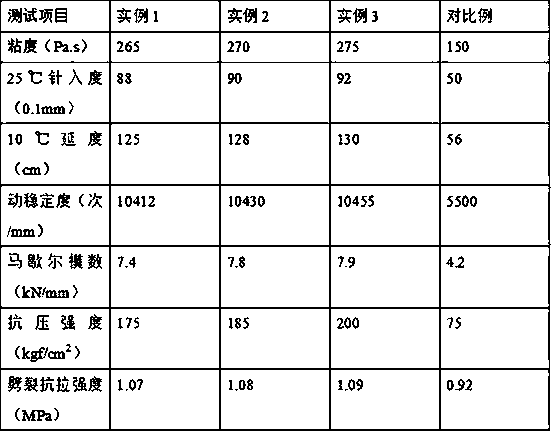

example 1

[0027] Put 100g of octanol polyoxyethylene ether into a three-necked flask, heat the three-necked flask to 50°C, mix and stir with a stirrer at a speed of 300r / min for 20min at a constant temperature, and add the quality of octanol polyoxyethylene ether dropwise into the three-necked flask 30% of the petroleum ether solution with a mass fraction of 20% dimethyldichlorosilane, control the rate of addition, and drop it within 50 minutes. After the addition is completed, continue to react at a constant temperature for 60 minutes. After the reaction, add a mass fraction of 15 % sodium hydroxide solution to adjust the pH value to neutral, and prepare a mixed solution for subsequent use; in parts by weight, weigh 3 parts of bagasse, 1 part of pig liver, 10 parts of rice straw and 6 parts of peanut oil and put them into the reaction kettle , mixed and stirred with a stirrer at a speed of 200r / min for 30min, after stirring, nitrogen was passed into the reactor to remove the air, and th...

example 2

[0029] Put 125g of octanol polyoxyethylene ether into a three-necked flask, heat the three-necked flask to 52°C, mix and stir with a stirrer at a speed of 320r / min for 25min at a constant temperature, and add the quality of octanol polyoxyethylene ether dropwise into the three-necked flask 32% of the petroleum ether solution with a mass fraction of 22% dimethyldichlorosilane, the rate of addition is controlled, and the dripping is completed within 55 minutes. After the addition is completed, the constant temperature reaction is continued for 65 minutes. % sodium hydroxide solution to adjust the pH value to neutral, and prepare a mixed solution for subsequent use; in parts by weight, 4 parts of bagasse, 1 part of pig liver, 11 parts of rice straw and 7 parts of peanut oil were weighed and put into the reaction kettle , mix and stir with a stirrer at a speed of 210r / min for 35min, after stirring, pass nitrogen into the reactor to remove the air, and increase the pressure in the r...

example 3

[0031] Put 150g of octanol polyoxyethylene ether into a three-necked flask, heat the three-necked flask to 55°C, mix and stir with a stirrer at a speed of 350r / min for 30min at a constant temperature, and add the quality of octanol polyoxyethylene ether dropwise into the three-necked flask 35% of the petroleum ether solution with a mass fraction of 25% dimethyldichlorosilane, control the rate of addition, and finish the dripping within 60 minutes. After the addition is completed, continue the constant temperature reaction for 70 minutes. After the reaction, add a mass fraction of 20 % sodium hydroxide solution to adjust the pH value to neutral, and prepare a mixed solution for subsequent use; in parts by weight, weigh 5 parts of bagasse, 2 parts of pig liver, 12 parts of rice straw and 8 parts of peanut oil and put them into the reaction kettle , mixed and stirred with a stirrer at a speed of 220r / min for 40min, after stirring, feed nitrogen into the reactor to remove air, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com