Intelligent control method of electroplating equipment for free mixed production of different products

An electroplating equipment and intelligent control technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low production efficiency, waste of electric energy, insufficient computing power to meet diversified production requirements, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

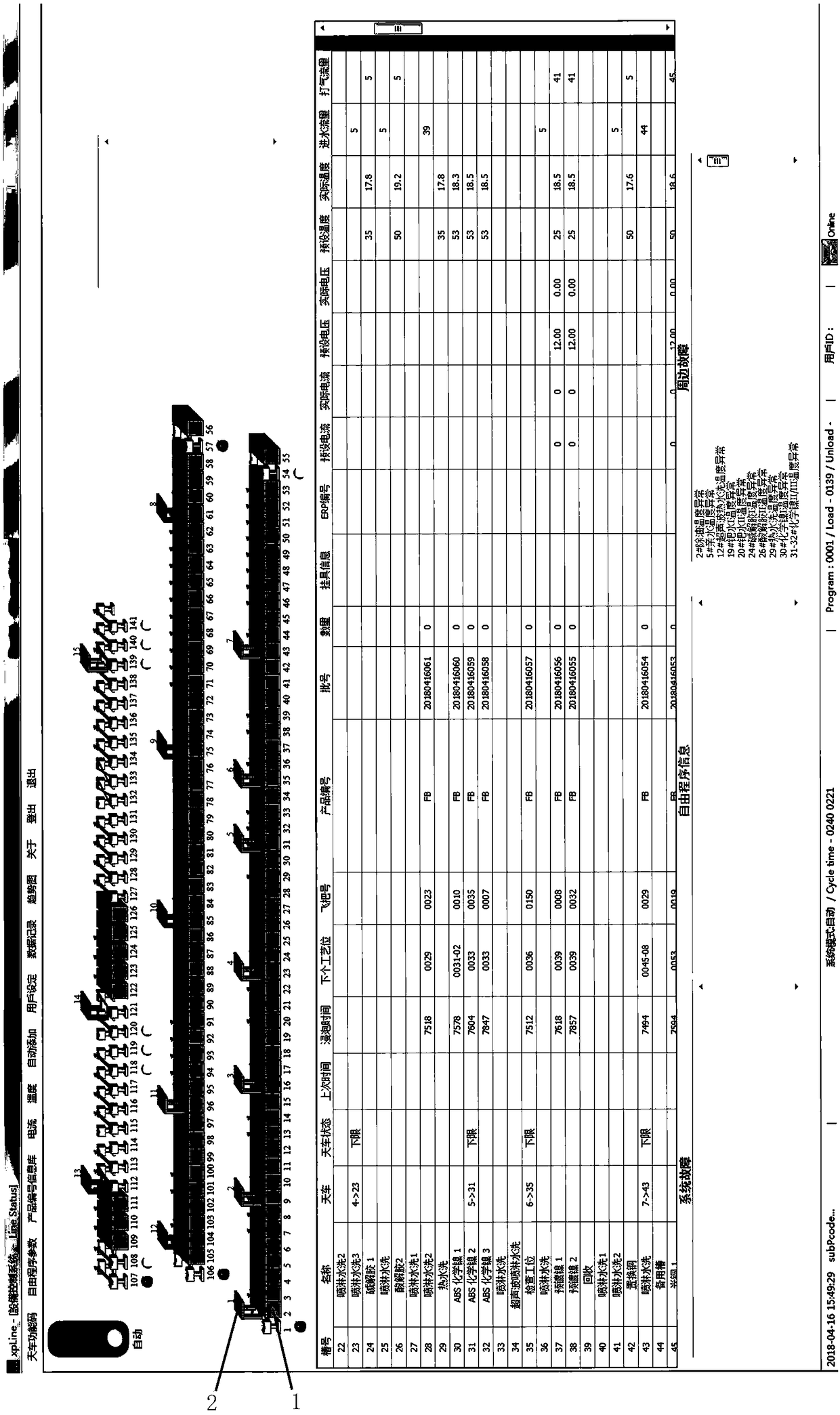

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0019] The present invention is an electroplating equipment intelligent control method for free mixed production of different products, which comprises the following steps:

[0020] S1: Provide electroplating equipment, which has multiple slots for performing electroplating production processes and a crane for transporting the products in the previous slot to the next slot;

[0021] S2: Number each product to be produced in the PC-side intelligent control system, so that a product has an independent material number, and the material number of the product corresponds to the product's process route, soaking time, dripping time, priority Grade, water basin action, and electroplating parameters are input into the PC-side intelligent control system of the system, and are bound to the material number; wherein, the electroplating parameters include curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com