Processing method for meLt-bLown non-woven cLoth containing short fibers

A technology of melt-blown nonwovens and processing methods, which is applied in the field of nonwovens, can solve problems such as inconvenient addition, uneven addition, and uneven mixing, and achieve the effects of improving utilization efficiency, convenient operation, and avoiding pollution of the workshop environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

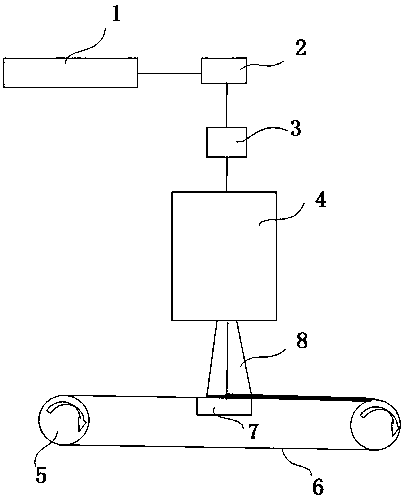

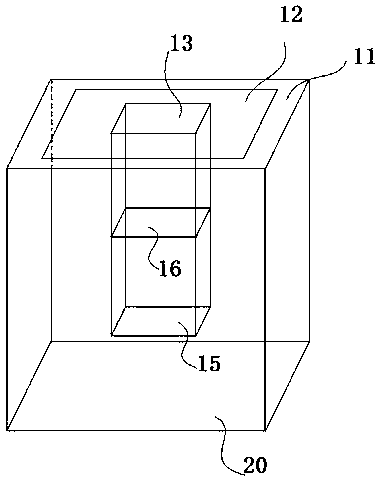

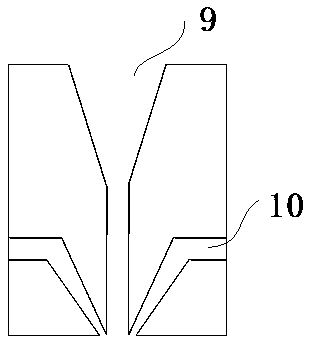

[0027] like Figure 1-4 , a method for processing melt-blown nonwoven fabrics containing short fibers, using a melt-blown nonwoven fabric processing device, the melt-blown nonwoven fabric processing device includes a screw extruder 1, a metering pump 2, a filter 3, a spray The silk mixing device 4 and the receiving device, the screw extruder 1, the metering pump 2, the filter 3 and the spinning mixing device 4 are sequentially connected through the melt conveying pipeline, and the mixed finished product 8 output by the spinning mixing device 4 is received by the receiving device; It is characterized in that: the spinner mixing device 4 includes a rectangular spinneret, a mixing chamber, an inner layer discharge device and a feed inlet, and the rectangular spinneret is divided into an outer edge area 11, a filament forming area 12 and a central A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com