Energy supply system of papermaking production line

A production line and energy supply technology, applied in the papermaking industry, can solve the problems of poor system operation efficiency, poor economy, and large heat loss, and achieve the effect of improving heat flux density, accelerating heat exchange rate, and ensuring heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

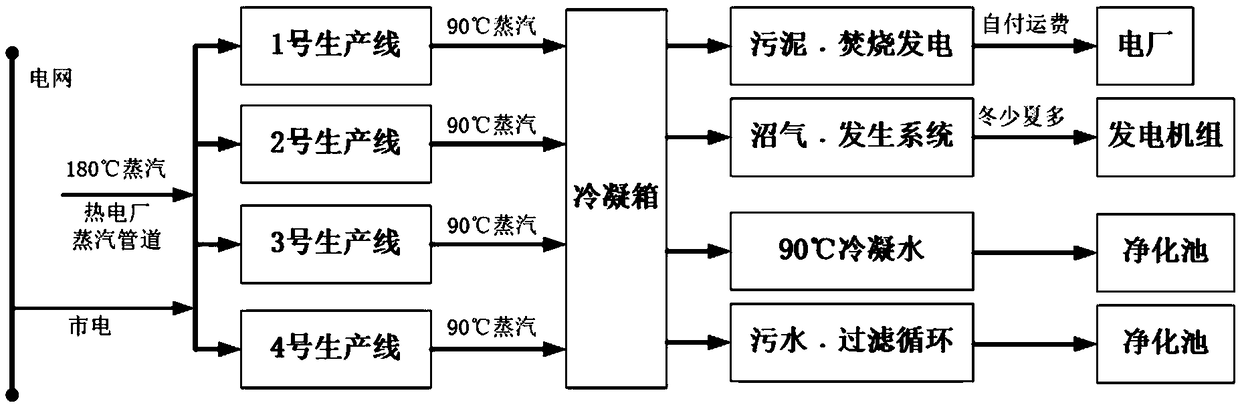

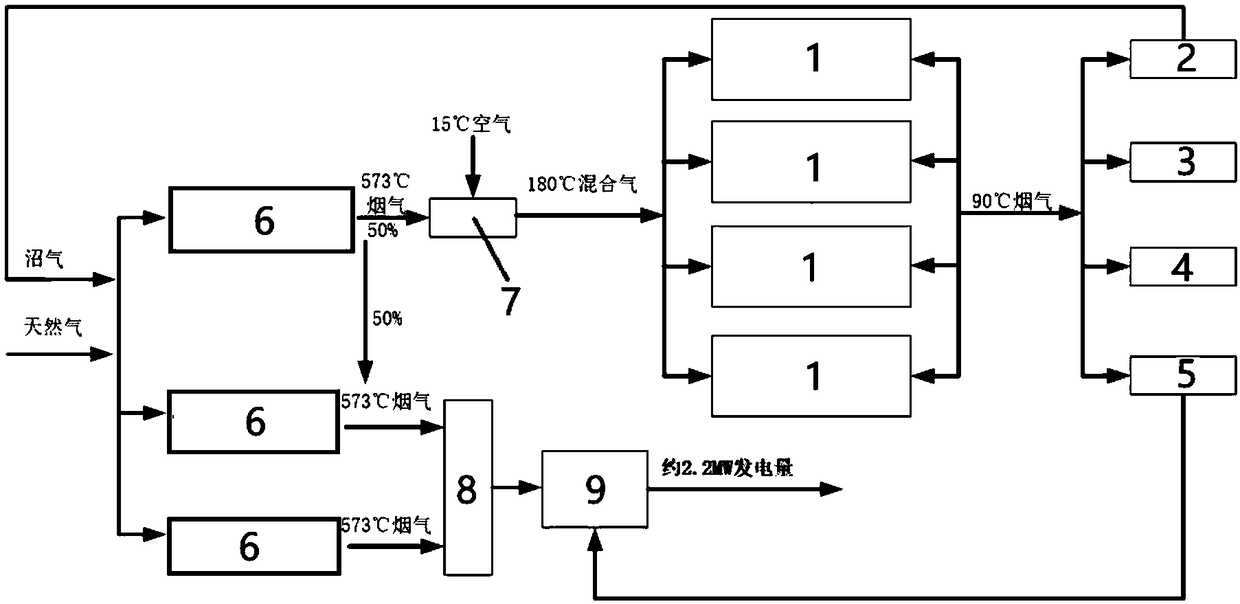

[0031] Such as figure 2 Shown, the energy supply system of papermaking production line of the present invention, papermaking production line comprises several pulp drying cylinders 1 and is arranged on the methane tank 2 of pulp drying cylinder 1 downstream, sludge drying device 3, sewage distillation device 4 and flue gas / Water heat exchanger 5, energy supply system includes several gas turbine generator sets 6, flue gas / air mixer 7, waste heat boiler 8, steam turbine generator set 9; each gas turbine generator set 6 burns natural gas and / or biogas tank 2 The generated biogas is used for electricity and high-temperature flue gas, which is used for the paper production line; at least one gas turbine generating set 6 generates part of the high-temperature flue gas that is passed into the flue gas / air mixer...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap