Combined frequency-conversion acoustic tile

A sound-absorbing brick, combined technology, applied in building materials, building components, sound insulation, etc., can solve the problem of low-frequency noise absorption, micro-perforated plate absorption peak frequency domain is not the same, micro-perforated plate is difficult to deal with the distribution of low-frequency noise, etc. problem, to achieve the effect of coping with noise intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific scheme of the combined frequency conversion sound-absorbing brick of the present invention is as follows.

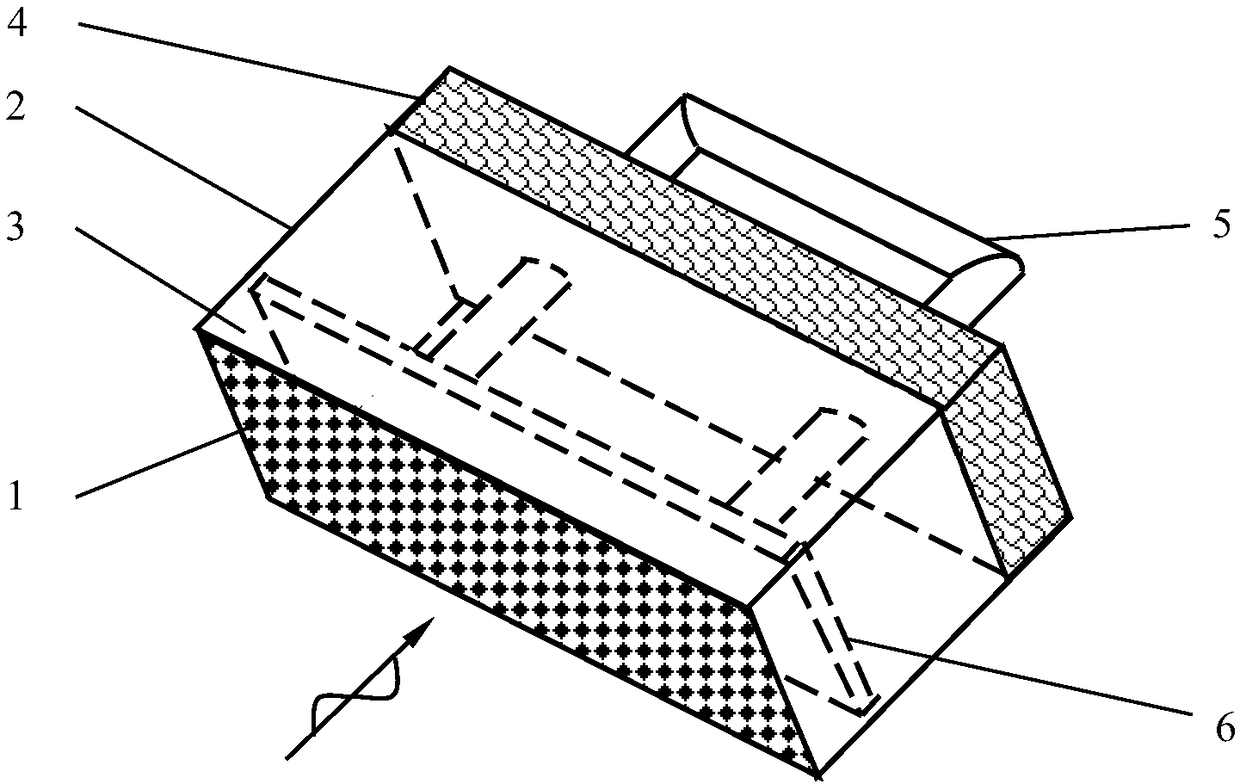

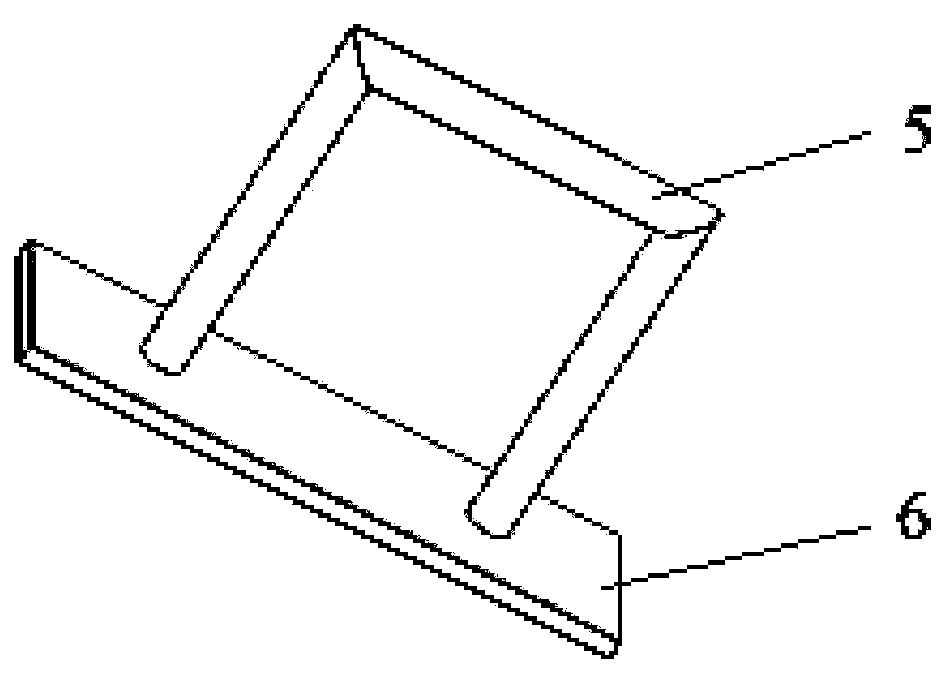

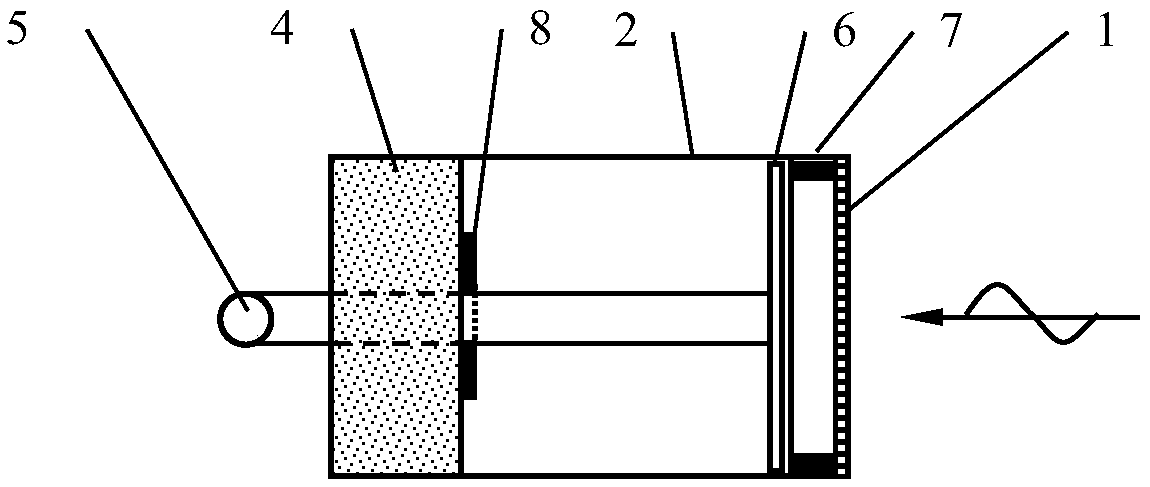

[0009] Such as figure 1 As shown, a cavity 3 is provided by the cavity 2 behind the micro-perforated plate 1, and a porous sound-absorbing plate 4 is arranged behind the cavity 3, and the respective lengths of the micro-perforated plate 1, the cavity 2, and the porous sound-absorbing plate 4 are , The width scale is the same as each other, for example, both are 300mm×100mm. The diameter of the micro-through holes on the micro-perforated plate 1 is 0.5 mm, the center-to-center distance between adjacent micro-through holes is 5.3 mm, the perforation rate is 0.7%, and the plate thickness is 0.5 mm. The plate thickness of cavity 2 is 5mm. The length and width of the cavity 3 are respectively less than three times the thickness of the cavity 3, such as length×width×thickness=290mm×90mm×100mm. The porous sound-absorbing board 4 is made of polyurethane ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com