Slot assembly type hollow glass brick and construction method thereof

A hollow glass and construction method technology, applied in building materials, building components, buildings, etc., can solve problems such as high requirements for construction technology, inability to lay circuit pipelines inside, and inconvenient construction of hollow glass brick walls, and achieve easy inspection and replacement , The effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

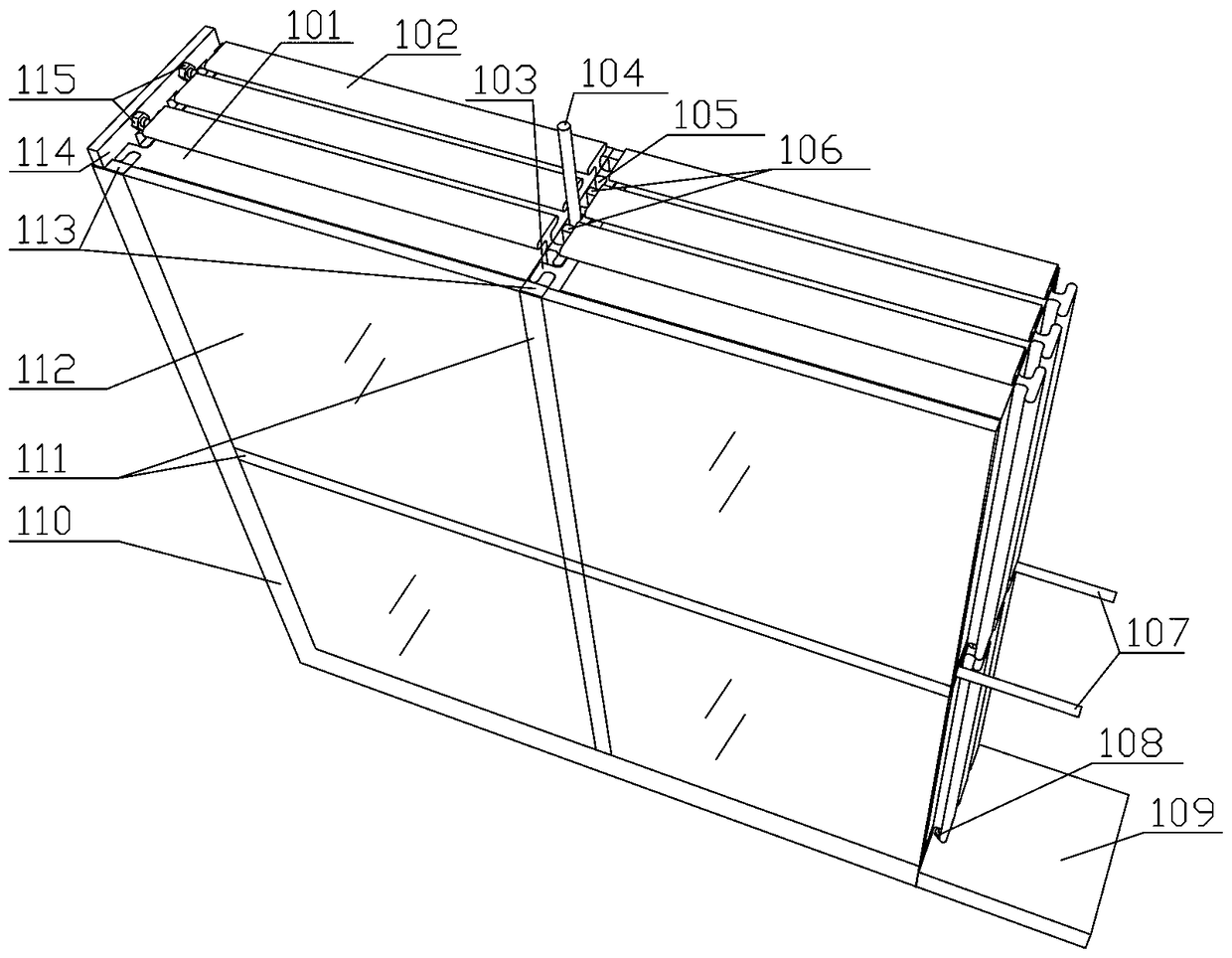

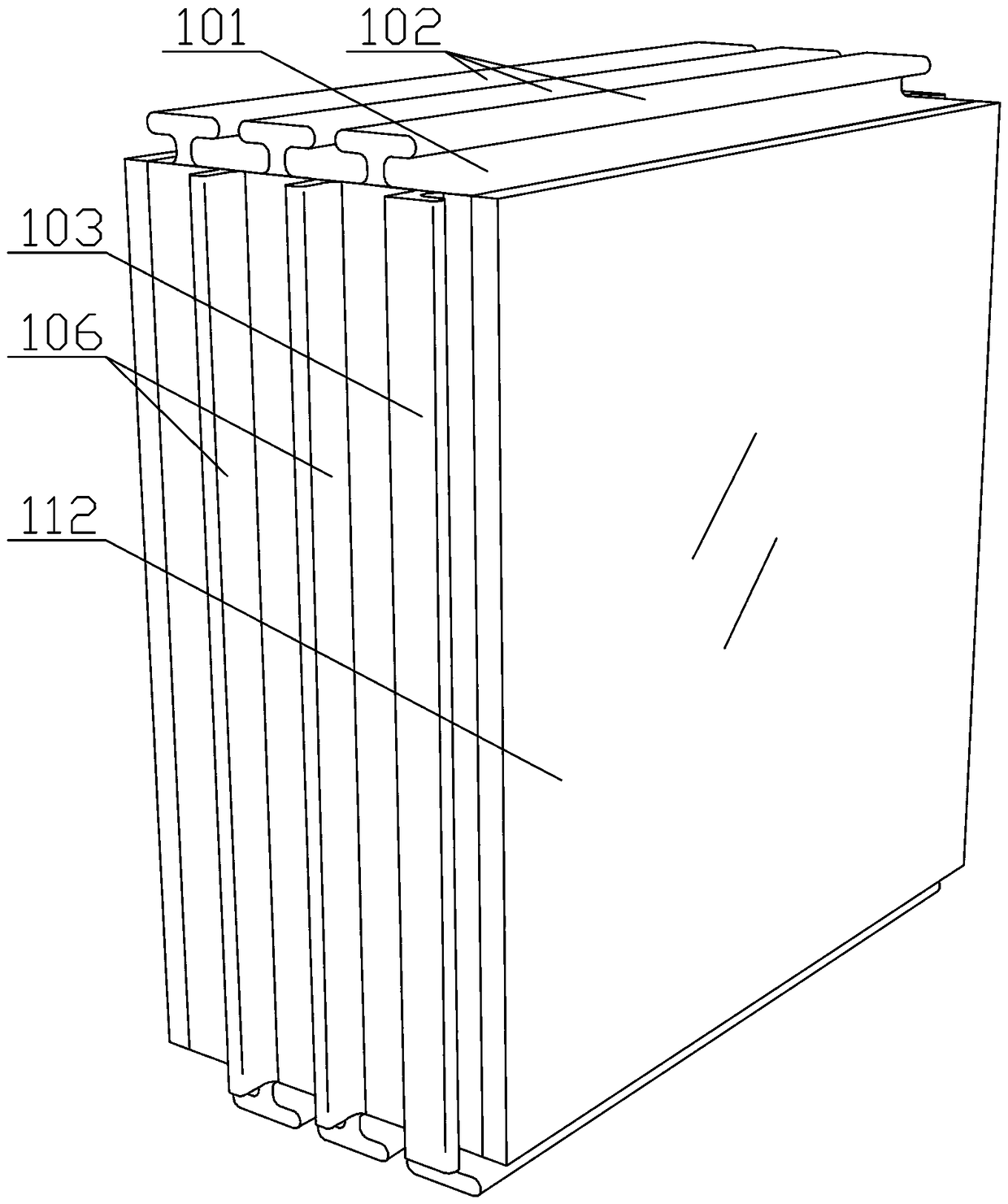

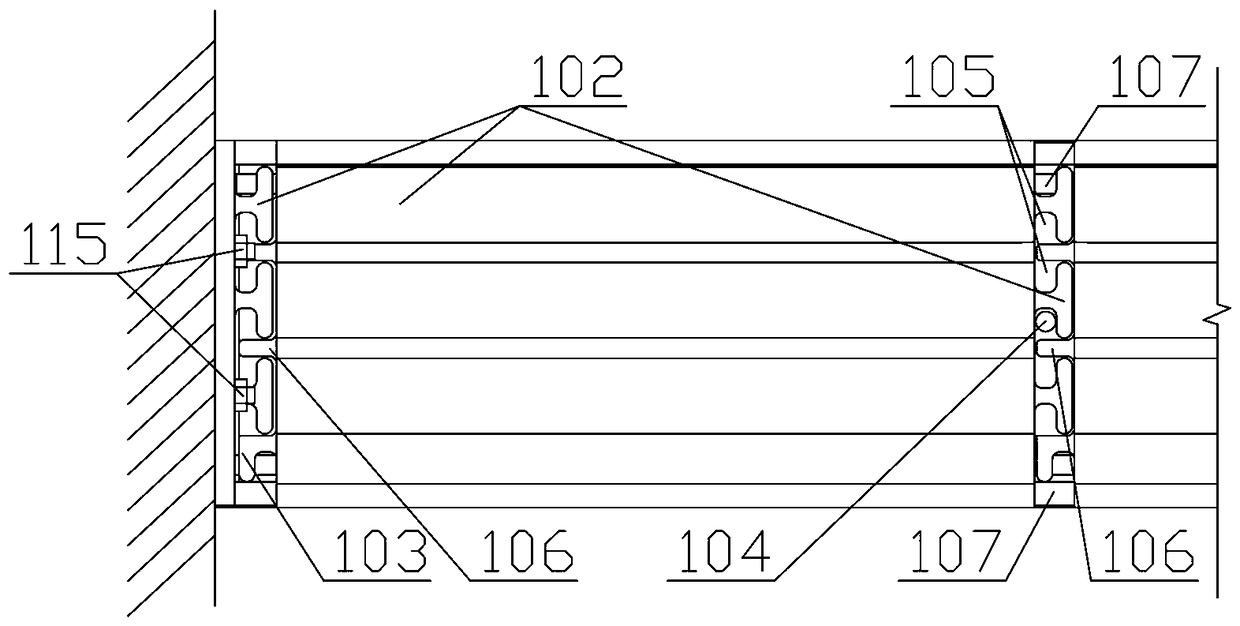

[0013] see figure 1 and figure 2 , the hollow glass block has slots on the four side walls of the upper, lower, left, and right sides. The upper, lower, and right sides are "T"-shaped slots (102), which engage with each other after plugged in (at the same time, the two ends and the middle three points are glued and fixed); the left side is "L"-shaped (103) and "I" "Type slot (106), the slot cavity (105) formed after being plugged and positioned with adjacent bricks or side slots, is used for laying reinforced steel bars or circuit pipelines. The bottom of the wall and the side frame of the wall also use positioning slots with "T"-shaped slots (102), and are fixed on the ground and side walls with the bottom positioning slot fixing bolts (108) and the side wall positioning slot fixing bolts (115) respectively. .

[0014] see image 3 , the slot cavity (105) formed after the "T"-shaped slot (102) on the right side of the left hollow glass block is plugged and positioned wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap