Building construction steel structure temporary bearing frame

A technology for building construction and bearing frame, which is applied to scaffolding supported by house structure, building structure, house structure support, etc., can solve the problems of insufficient lateral and vertical bearing capacity, reducing the practical life of the frame, hidden dangers of the frame, etc. To achieve the effect of increasing manned cargo capacity, improving operational efficiency and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

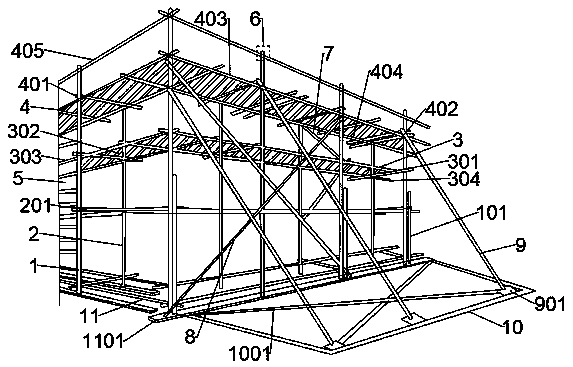

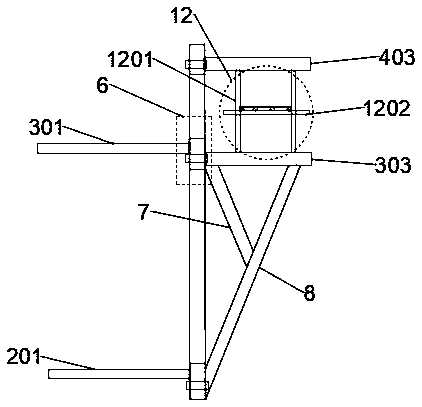

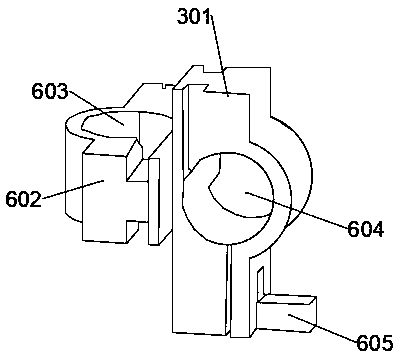

[0043] like Figure 1 to Figure 8 As shown, the present invention provides a steel structure temporary load-bearing frame for building construction, comprising several outer poles 1 and several inner poles 2, and the bottom ends of the outer poles 1 and the inner poles 2 are jointly connected with a stable chassis 11. A middle bearing frame 3 is arranged between the outer pole 1 and the inner pole 2, and a top bearing frame 4 is arranged on the top of the outer pole 1 and the inner pole 2, and the middle bearing frame 3 and the top bearing frame 4 are connected There are oblique support rods 7, a scissor support frame 8 is connected between the leftmost and rightmost outer vertical rods 1, and the outer side of the top floor carrier 4 is connected with any angle between 45-70 degrees with the ground The obliquely placed force-bearing column 9, the bottom end of the obliquely placed force-bearing column 9 is connected with a balance bottom frame 10, and a climbing ladder 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com